Are you gearing up for an interview for a Electric Arc Welder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Electric Arc Welder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

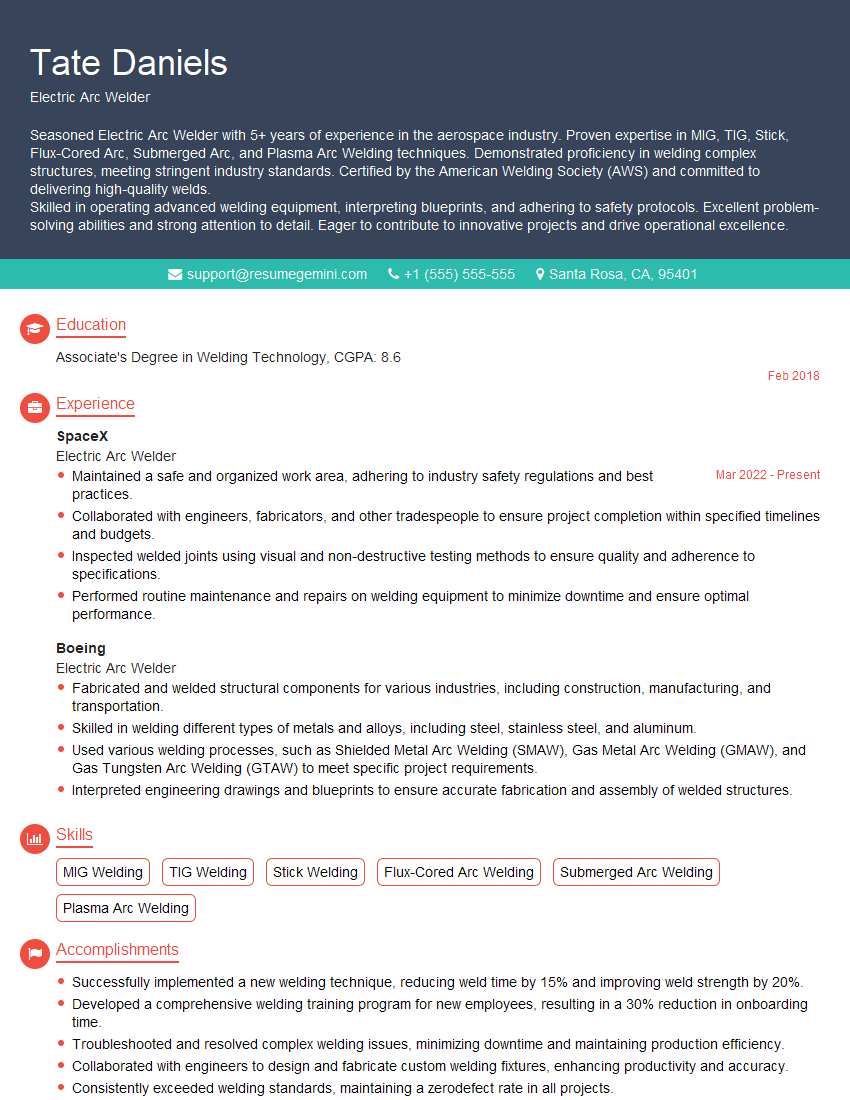

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electric Arc Welder

1. What are the different types of electric arc welding processes?

- Shielded metal arc welding (SMAW)

- Gas metal arc welding (GMAW)

- Gas tungsten arc welding (GTAW)

- Flux-cored arc welding (FCAW)

- Submerged arc welding (SAW)

2. What are the advantages and disadvantages of each process?

SMAW

- Advantages: Portable, low cost, versatile

- Disadvantages: Slow, high fume production

GMAW

- Advantages: Fast, low spatter, high quality

- Disadvantages: Requires shielding gas, can be difficult to weld in windy conditions

GTAW

- Advantages: High quality, no spatter, can weld thin materials

- Disadvantages: Slow, requires skilled welder

FCAW

- Advantages: Fast, high deposition rate, versatile

- Disadvantages: High fume production, can be difficult to control weld puddle

SAW

- Advantages: High quality, high deposition rate, automated

- Disadvantages: High cost, requires specialized equipment

3. What is the difference between AC and DC welding?

- AC welding: Alternating current, produces a more fluid weld pool, less penetration, can be used on thinner materials

- DC welding: Direct current, produces a more concentrated weld pool, greater penetration, can be used on thicker materials

4. What is the purpose of a welding rod?

- To provide filler metal for the weld joint

- To stabilize the arc

- To protect the weld pool from the atmosphere

5. What are the different types of welding rods?

- Solid rods

- Flux-cored rods

- Metal-cored rods

6. How do you select the correct welding rod for a job?

- Consider the base metal

- Consider the welding process

- Consider the joint design

- Consider the desired weld properties

7. What are the safety precautions that should be taken when welding?

- Wear appropriate protective clothing

- Use a welding helmet with a proper shade lens

- Ventilate the work area

- Keep flammable materials away from the welding area

- Be aware of the fire hazards associated with welding

8. What are the common problems that can occur when welding?

- Porosity

- Cold lap

- Undercut

- Spatter

- Warpage

9. How do you troubleshoot welding problems?

- Inspect the weld joint

- Check the welding equipment

- Adjust the welding parameters

- Consult with a welding expert

10. What are the latest trends in welding technology?

- Robotic welding

- Laser welding

- Friction stir welding

- Electron beam welding

- Plasma arc welding

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electric Arc Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electric Arc Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electric Arc Welders are responsible for joining metal components using electric arc welding techniques. They interpret technical drawings and welding specifications to determine the appropriate materials, equipment, and techniques to use. Key responsibilities include:

1. Preparation and Setup

Electric Arc Welders prepare and set up welding equipment according to specifications. They select the appropriate welding rods, electrodes, and shielding gases based on the materials being welded.

- Inspect and clean metal surfaces to ensure proper adhesion.

- Position and secure materials for welding.

2. Welding

Electric Arc Welders operate welding equipment to join metal components. They use various welding techniques, such as stick welding, MIG welding, and TIG welding, to create strong and durable joints.

- Maintain a stable arc and control the heat input to achieve proper weld quality.

- Inspect welds for defects and make necessary repairs.

3. Inspection and Testing

Electric Arc Welders inspect welds to ensure they meet quality standards. They use visual inspection techniques, as well as non-destructive testing methods, to detect any defects.

- Interpret welding symbols and specifications to verify weld dimensions and quality.

- Perform post-weld heat treatment to enhance the strength and properties of the weld.

4. Safety and Maintenance

Electric Arc Welders are responsible for maintaining a safe work environment. They follow safety procedures to prevent accidents and protect themselves and others from hazards.

- Wear appropriate personal protective equipment (PPE), such as welding helmets, gloves, and protective clothing.

- Maintain welding equipment and ensure it is in good working order.

Interview Preparation Tips

To ace an interview for an Electric Arc Welder position, candidates should follow these preparation tips:

1. Research the Company and Industry

Research the company, its values, and its products or services. Understand the industry in which the company operates and its key players. This knowledge will allow you to tailor your answers to the interviewer’s questions and demonstrate your interest in the company.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

2. Practice Your Welding Skills

Employers will often ask candidates to demonstrate their welding skills during the interview. Practice your welding techniques to ensure you perform well during the assessment. Consider practicing on scrap metal or sheet metal to improve your accuracy and consistency.

- Review welding safety procedures and best practices.

- Bring a portfolio of your welding work to the interview.

3. Prepare for Technical Questions

Prepare for technical questions related to welding techniques, materials, and equipment. Review welding symbols, welding codes, and industry standards. Be prepared to discuss your knowledge of different types of welds, joint designs, and welding processes.

- Study welding terminology and definitions.

- Practice answering common welding interview questions.

4. Highlight Your Safety Awareness

Employers prioritize safety in welding environments. Emphasize your commitment to safety by highlighting your knowledge of industry safety standards and best practices. Explain your experience with personal protective equipment (PPE) and safe welding practices.

- Familiarize yourself with OSHA regulations and safety guidelines.

- Share examples of how you have promoted safety in previous roles.

Next Step:

Now that you’re armed with the knowledge of Electric Arc Welder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Electric Arc Welder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini