Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Getter Welder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

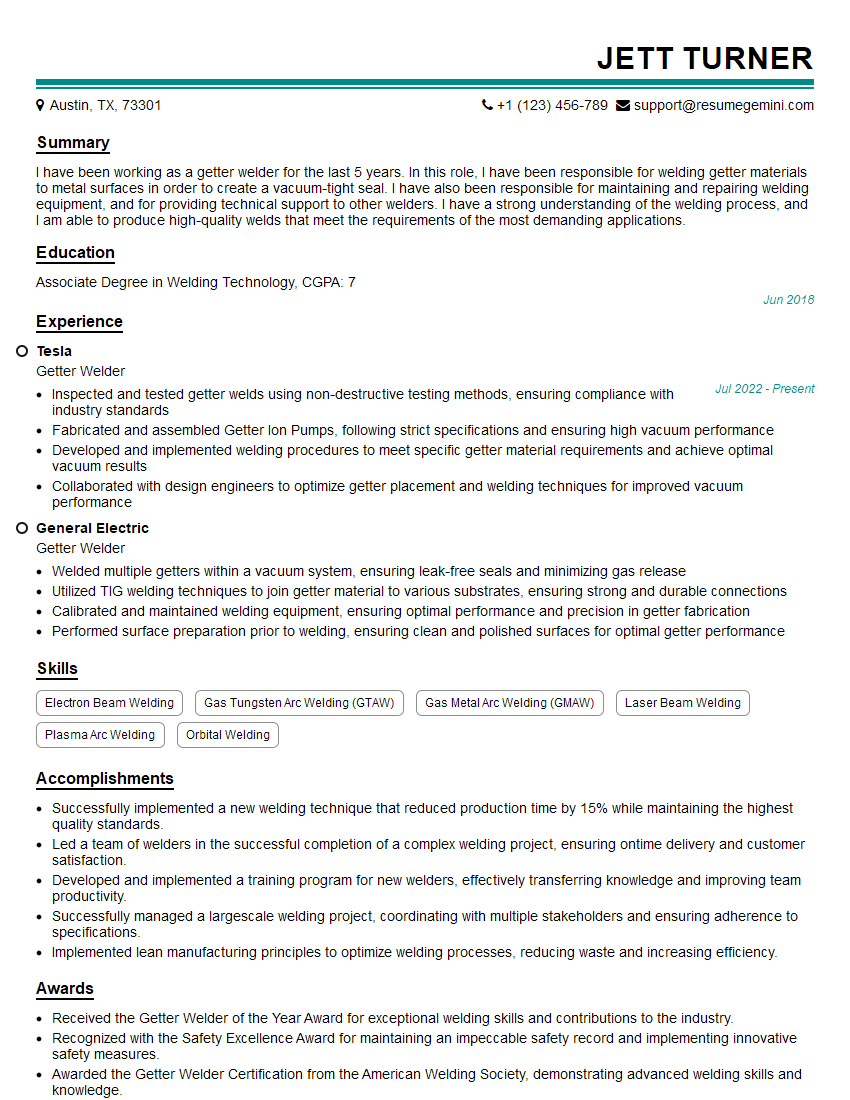

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Getter Welder

1. Describe the different types of welding processes you are familiar with.

In my experience, I have worked with a variety of welding processes, including:

- Gas Tungsten Arc Welding (GTAW) also known as TIG welding

- Gas Metal Arc Welding (GMAW) also known as MIG welding

- Shielded Metal Arc Welding (SMAW) also known as stick welding

- Flux-cored Arc Welding (FCAW)

- Submerged Arc Welding (SAW)

2. Can you explain the difference between a butt joint and an edge joint?

Butt Joint

- A butt joint is a joint where two pieces of metal are placed end-to-end and welded together.

- This type of joint is often used when the pieces of metal are of equal thickness.

Edge Joint

- An edge joint is a joint where the edges of two pieces of metal are welded together.

- This type of joint is often used when the pieces of metal are of different thicknesses.

3. What are the different types of welding positions?

There are four main welding positions:

- Flat position: This is the most common welding position, and it is used when the workpiece is flat on a table or other surface.

- Horizontal position: This position is used when the workpiece is horizontal, such as when welding a pipe.

- Vertical position: This position is used when the workpiece is vertical, such as when welding a wall.

- Overhead position: This position is used when the workpiece is overhead, such as when welding a ceiling.

4. What are the different types of welding defects?

There are many different types of welding defects, but some of the most common include:

- Porosity: This is a defect that occurs when there are small holes in the weld.

- Slag inclusions: This is a defect that occurs when pieces of slag are trapped in the weld.

- Undercut: This is a defect that occurs when the weld metal does not fully penetrate the base metal.

- Overcut: This is a defect that occurs when the weld metal penetrates the base metal too deeply.

5. What are the different types of welding fluxes?

There are many different types of welding fluxes, but some of the most common include:

- Acid fluxes: These fluxes are used to remove oxides from the surface of the metal.

- Alkaline fluxes: These fluxes are used to protect the weld metal from oxidation.

- Neutral fluxes: These fluxes do not react with the metal.

6. What are the different types of welding electrodes?

There are many different types of welding electrodes, but some of the most common include:

- Carbon steel electrodes: These electrodes are made from carbon steel and are used to weld carbon steel.

- Stainless steel electrodes: These electrodes are made from stainless steel and are used to weld stainless steel.

- Aluminum electrodes: These electrodes are made from aluminum and are used to weld aluminum.

7. What are the different types of welding machines?

There are many different types of welding machines, but some of the most common include:

- Arc welding machines: These machines use an electric arc to melt the metal.

- Resistance welding machines: These machines use pressure and heat to weld the metal.

- Laser welding machines: These machines use a laser to melt the metal.

8. What are the safety precautions that must be taken when welding?

There are many safety precautions that must be taken when welding, including:

- Wearing protective clothing, such as a welding helmet, gloves, and apron.

- Ensuring that the work area is well-ventilated.

- Using proper welding techniques to avoid creating defects.

- Storing welding equipment properly to prevent fires.

9. What are the different types of welding certifications?

There are many different types of welding certifications, but some of the most common include:

- American Welding Society (AWS) certifications

- Canadian Welding Bureau (CWB) certifications

- International Institute of Welding (IIW) certifications

10. What is your experience with welding different types of metals?

I have experience welding a variety of metals, including:

- Carbon steel

- Stainless steel

- Aluminum

- Copper

- Titanium

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Getter Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Getter Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Getter welders play a vital role in vacuum technology, specializing in joining components by applying heat using getters to create a high-vacuum environment. Their primary responsibilities include:

1. Getter Application

Apply getters to metal surfaces using specialized techniques, such as evaporation or sputtering, to enhance vacuum quality by removing residual gases.

- Select appropriate getters based on system requirements.

- Determine optimal getter placement and quantity for maximum effectiveness.

2. Vacuum Chamber Preparation

Prepare and maintain vacuum chambers by cleaning and degassing surfaces, installing components, and ensuring proper sealing.

- Clean and degrease chamber surfaces to eliminate contaminants.

- Degas components to remove trapped gases that can impair vacuum quality.

3. Welding Operations

Perform welding operations to join components within vacuum chambers, ensuring leak-tight seals and structural integrity.

- Use specialized welding techniques, such as TIG welding, to achieve precise and reliable welds.

- Inspect welds for defects and ensure compliance with quality standards.

4. Leak Detection and Repair

Detect and repair leaks in vacuum systems using specialized equipment, such as helium leak detectors.

- Locate leaks using precision leak detection techniques.

- Implement appropriate repair methods to seal leaks and maintain vacuum integrity.

Interview Tips

Interview Tips

1. Research the Role and Company

Thoroughly read the job description and visit the company’s website to gain a clear understanding of their products and services. This will help you align your skills and experience with the role and demonstrate your interest in the company.

- Highlight your expertise in getter application techniques, such as evaporation and sputtering.

- Emphasize your understanding of vacuum chamber preparation and degassing processes.

2. Showcase Your Welding Experience

Provide specific examples of your welding skills and experience in a vacuum environment. Describe the types of welds you have performed and the methods you used to ensure high-quality results.

- Quantify your work whenever possible, using specific metrics and results.

- Explain your problem-solving abilities and how you have overcome challenges related to welding in vacuum systems.

3. Highlight Your Leak Detection and Repair Skills

Describe your experience in using helium leak detectors and other techniques to identify and repair leaks in vacuum systems.

- Share examples of successful leak repairs you have performed, emphasizing your analytical and troubleshooting skills.

- Explain your understanding of different leak repair methods and how you select the most appropriate approach for each situation.

4. Prepare for Technical Questions

Expect technical questions related to getter welding principles, vacuum chamber design, and welding techniques. Be prepared to discuss topics such as getter selection, degassing processes, and weld inspection criteria.

- Review relevant technical materials and practice answering common interview questions.

- Prepare questions of your own to show your interest and engagement in the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Getter Welder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!