Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Gas Welder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

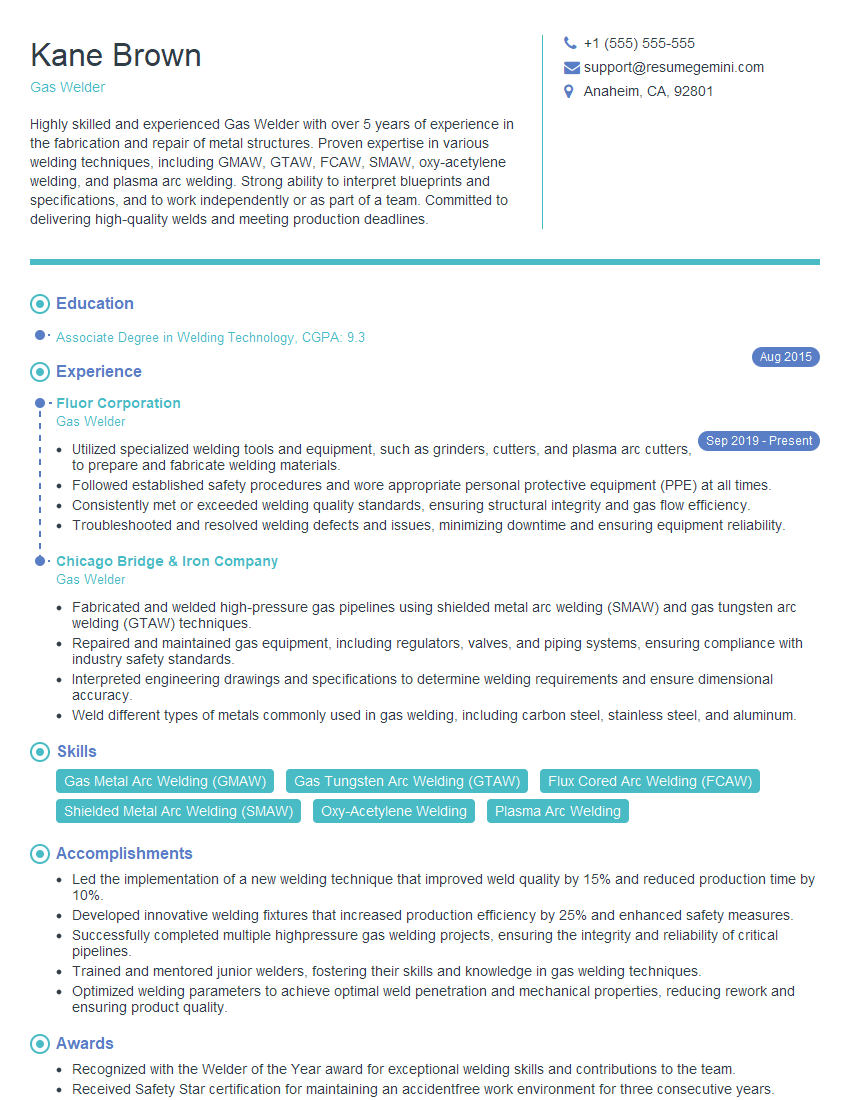

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gas Welder

1. What are the different types of gas welding processes?

There are three primary gas welding processes:

- Oxy-acetylene welding

- Oxy-fuel gas welding

- Plasma arc welding

2. What are the safety precautions that must be followed when gas welding?

Equipment Safety

- Regularly inspect and maintain equipment for leaks or damages

- Ensure proper ventilation to prevent gas build-up

Personal Safety

- Wear appropriate protective clothing (flame-resistant coveralls, gloves, etc.)

- Shield eyes with a welding helmet or goggles

3. How do you determine the correct gas flow rate for a given welding operation?

- Refer to manufacturer’s specifications for the specific gas and welding process

- Consider the material thickness, joint type, and welding speed

- Adjust gas flow rate to achieve proper flame or plasma characteristics

4. What are the different types of welding joints and when are they used?

- Butt joint: Joining two pieces of metal edge-to-edge, used for sheets and pipes

- Edge joint: Joining two pieces of metal along their edges, used for sheets and plates

- T-joint: Joining a perpendicular piece of metal to another, used for framing and supports

- Corner joint: Joining two pieces of metal at a 90-degree angle, used for boxes and frames

5. How do you prepare metal surfaces for gas welding?

- Clean surfaces thoroughly to remove dirt, oil, and rust

- Bevel edges if necessary to create a V- or U-shaped groove

- Use a flux to remove oxides and improve weld quality

6. What are the different types of welding torches and when are they used?

- Neutral flame torch: Equal amounts of oxygen and fuel gas, used for most welding applications

- Oxidizing flame torch: More oxygen than fuel gas, used for cutting metal

- Reducing flame torch: More fuel gas than oxygen, used for brazing and soldering

- Plasma torch: Uses an electric arc to create a plasma jet, used for precision welding and cutting

7. How do you troubleshoot common gas welding problems?

- Porosity: Adjust gas flow rate or use a different welding technique

- Cold lap: Increase heat input or adjust welding speed

- Undercut: Decrease heat input or adjust torch angle

- Burn-through: Decrease heat input or increase welding speed

8. What are the quality control measures for gas welding?

- Visual inspection: Check for defects such as cracks, porosity, and undercut

- Non-destructive testing: Use methods like radiography or ultrasonic testing to detect internal defects

- Destructive testing: Perform tensile or bend tests to assess weld strength

9. What are the advantages and disadvantages of gas welding compared to other welding processes?

Advantages:

- Versatile, can be used on various metals and thicknesses

- Portable, equipment can be easily moved to different locations

- Relatively low cost to set up and operate

Disadvantages:

- Slower welding speeds compared to other processes

- Requires skilled operators to achieve high-quality welds

- Produces fumes and gases that require ventilation

10. Describe a challenging gas welding project you have worked on and how you overcame the challenges.

Provide a specific example of a project where you faced technical difficulties, such as welding a thick or complex joint, and explain the steps you took to resolve the issues and achieve a successful outcome.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gas Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gas Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gas Welders are responsible for joining metal components using oxy-fuel or other gas welding processes. They must be able to interpret blueprints and drawings, set up and operate welding equipment, and inspect welds for quality. Key job responsibilities include:

1. Preparing and Joining Metal Components

Gas Welders prepare metal components for welding by cleaning and beveling edges. They then position the components and secure them in place. They use cutting torches to cut metal as needed.

2. Operating Welding Equipment

Gas Welders operate oxy-fuel welding equipment, which includes torches, regulators, and hoses. They adjust the gas flow and flame settings to achieve the desired weld quality.

3. Inspecting Welds

Gas Welders inspect welds for quality using visual inspection techniques. They check for defects such as cracks, undercut, and porosity. They also measure weld dimensions to ensure they meet specifications.

4. Maintaining Equipment

Gas Welders are responsible for maintaining their welding equipment. They clean and lubricate equipment regularly and perform minor repairs as needed.

Interview Tips

Preparing for an interview for a Gas Welder position can be daunting, but with the right preparation, you can increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and what they are looking for in a Gas Welder.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Why do you want to work for this company?” and “What are your strengths and weaknesses?”. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

4. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic about the position and who have a positive attitude. Be sure to convey your excitement about the opportunity to work for the company and to highlight your skills and experience.

5. Follow Up After the Interview

After the interview, take some time to follow up with the interviewer. Thank them for their time and reiterate your interest in the position. This shows the interviewer that you are still interested in the job and that you are willing to go the extra mile.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gas Welder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!