Feeling lost in a sea of interview questions? Landed that dream interview for Gas Cutter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Gas Cutter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

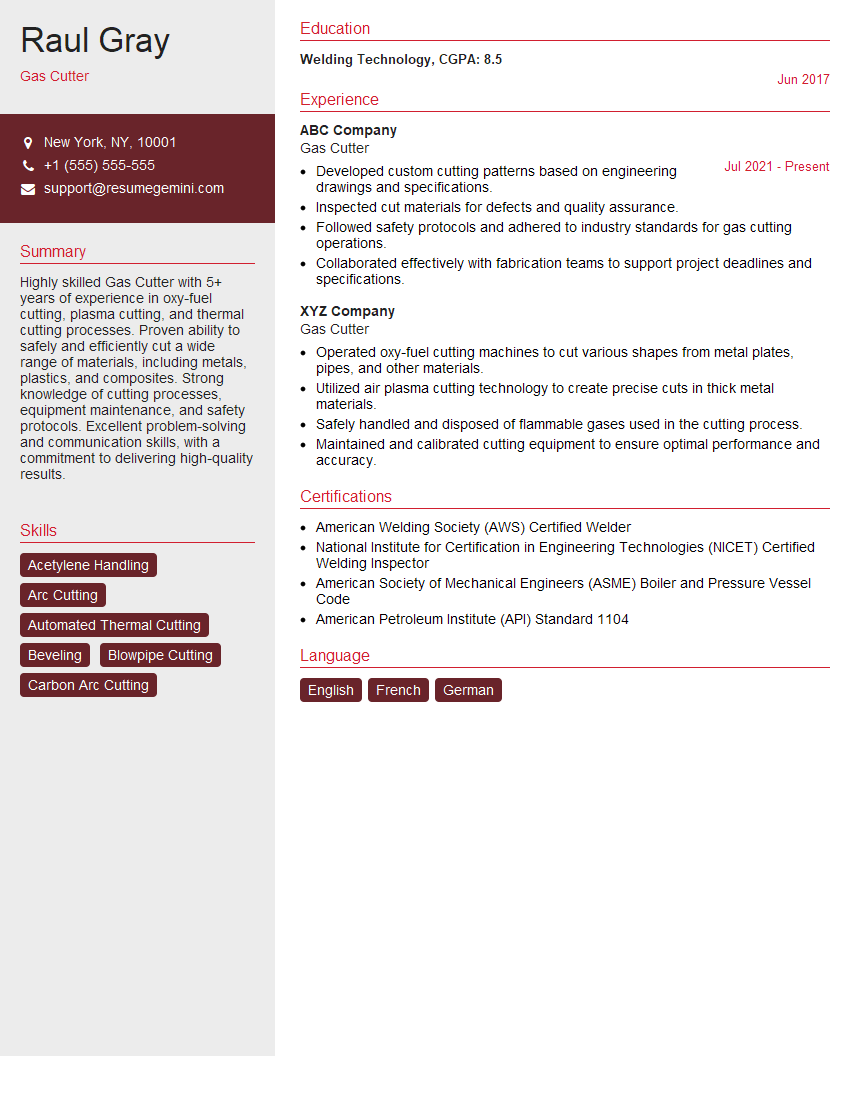

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gas Cutter

1. What are the different types of gas cutting equipment and their applications?

- Oxy-fuel cutting: Uses a mixture of oxygen and fuel gas to cut metal.

- Plasma cutting: Uses plasma torch to cut metal.

- Laser cutting: Uses a laser beam to cut metal.

- Waterjet cutting: Uses a high-pressure stream of water to cut metal.

2. What are the safety precautions that need to be taken while operating a gas cutter?

- Wear proper personal protective equipment (PPE) such as eye protection, gloves, and fire-resistant clothing.

- Ensure adequate ventilation to avoid the inhalation of harmful gases.

- Use the correct gas pressure and flow rates.

- Keep the cutting torch clean and in good working order.

3. How do you determine the correct cutting speed and angle for a given material and thickness?

- Refer to manufacturer’s recommendations for the specific material and thickness.

- Experiment with different speeds and angles to find the optimal settings.

- Consider the type of gas cutting equipment being used.

4. What are the different techniques used for cutting complex shapes with a gas cutter?

- Use templates or stencils to guide the cutting torch.

- Freehand cutting requires skill and experience.

- Computer-controlled cutting systems provide high precision and repeatability.

5. How do you maintain and troubleshoot a gas cutter?

- Regularly clean and inspect the cutting torch and hoses.

- Check for leaks and replace worn or damaged parts.

- Troubleshoot common problems such as incorrect gas pressure or torch malfunction.

6. What are the different types of gases used in gas cutting and their properties?

- Oxygen: Supports combustion and provides the heat for cutting.

- Fuel gases: Include acetylene, propane, and natural gas, which provide the fuel for combustion.

- Inert gases: Such as argon or helium, can be used to protect the cut surface from oxidation.

7. How do you ensure the accuracy and quality of gas cutting operations?

- Use precision measuring tools to mark the cutting lines.

- Hold the cutting torch perpendicular to the surface being cut.

- Control the cutting speed and angle.

- Inspect the cut quality regularly and make adjustments as needed.

8. What are the common defects that can occur in gas cutting and how can they be prevented?

- Dross: Slag formed on the cut surface

- Warping: Distortion of the metal due to heat

- Undercut: Cutting below the desired depth

- Overcut: Cutting beyond the desired width

9. How do you apply gas cutting techniques in different industries, such as construction, manufacturing, and shipbuilding?

- Construction: Cutting structural steel, beams, and plates

- Manufacturing: Cutting parts and components from sheet metal

- Shipbuilding: Cutting steel plates and sections

10. What are the latest advancements in gas cutting technology?

- Automated gas cutting systems

- Plasma cutting with higher power and precision

- Laser cutting with improved cutting speed and accuracy

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gas Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gas Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Gas Cutters are skilled tradespeople who use oxy-fuel torches or plasma cutters to cut metal. They work in various industries, including construction, manufacturing, and shipbuilding.

1. Cutting and Shaping Metal

Gas Cutters primary responsibility is to cut and shape metal using oxy-fuel torches or plasma cutters. They must be able to operate these machines safely and efficiently, and they must be able to produce precise cuts.

- Use oxy-fuel torches or plasma cutters to cut metal

- Operate machines safely and efficiently

- Produce precise cuts

2. Preparing Metal for Cutting

Before cutting metal, Gas Cutters must prepare the metal by cleaning it and removing any dirt or debris. They must also mark the metal where they will be cutting.

- Clean metal before cutting

- Remove dirt or debris

- Mark metal where it will be cut

3. Reading Blueprints and Specifications

Gas Cutters must be able to read blueprints and specifications to understand the project’s requirements. They must be able to follow instructions and work within the specified tolerances.

- Read blueprints and specifications

- Understand project requirements

- Follow instructions

- Work within specified tolerances

4. Safety

Gas Cutters must follow all safety regulations when working with oxy-fuel torches or plasma cutters. They must wear appropriate personal protective equipment (PPE), and they must be aware of the hazards associated with these machines.

- Follow safety regulations

- Wear appropriate PPE

- Be aware of hazards

Interview Tips

To ace a Gas Cutter interview, you must prepare adequately. Here are some tips to help you succeed:

1. Research the Company and the Position

Before the interview, take some time to research the company and the specific position you’re applying for. This will give you a good understanding of the company’s culture and the expectations for the role.

- Visit the company website

- Read about the company’s mission, values, and products or services

- Learn about the specific position you’re applying for

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice your answers to these questions so that you can deliver them confidently and concisely.

- Use the STAR method to answer interview questions

- Situation: Describe the situation or task you were faced with.

- Task: Explain your role and responsibilities in the situation.

- Action: Describe the specific actions you took to address the situation.

- Result: Explain the outcome of your actions and what you learned from the experience.

3. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of the interview shows that you’re interested in the position and the company. It’s also a good way to learn more about the role and the organization.

- What are the biggest challenges facing the company right now?

- What are the company’s goals for the next year?

- What are the opportunities for advancement within the company?

4. Dress Professionally and Arrive on Time

First impressions matter, so make sure you dress professionally for your interview. You should also arrive on time to show that you’re respectful of the interviewer’s time.

- Wear a clean, pressed shirt and pants or a skirt

- Wear closed-toe shoes

- Arrive 10-15 minutes early for your interview

5. Be Yourself and Be Confident

The most important thing is to be yourself and be confident in your abilities. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Be honest and open in your answers

- Make eye contact with the interviewer

- Speak clearly and confidently

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Gas Cutter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Gas Cutter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.