Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Oxyhydrogen Welder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

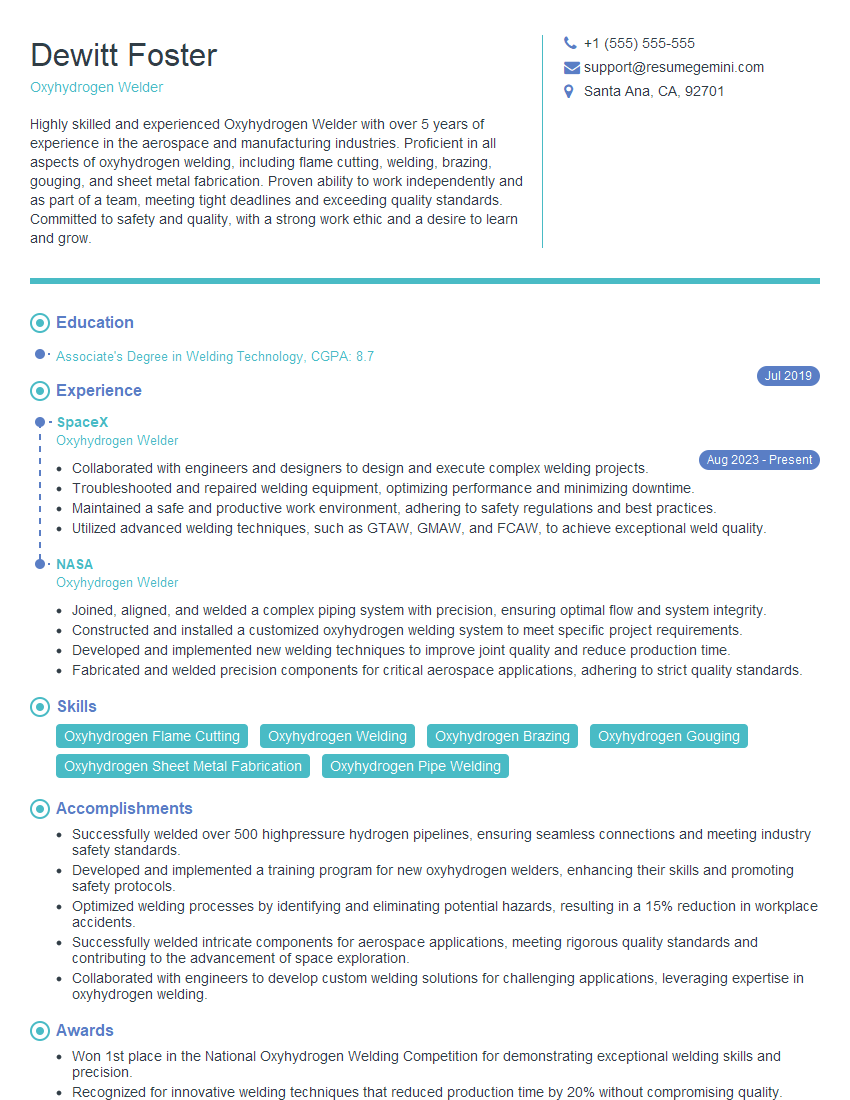

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oxyhydrogen Welder

1. Describe the process of oxyhydrogen welding.

Oxyhydrogen welding involves generating a high-temperature flame by mixing hydrogen and oxygen gases. This flame is then used to weld metal pieces together.

- The first step is to connect the oxyhydrogen torch to the hydrogen and oxygen gas supplies.

- The gases are then mixed in the torch and ignited to create a flame.

- The welder directs the flame at the metal pieces to be welded, melting the metal and causing it to fuse together.

- The welded joint is then allowed to cool and solidify, creating a strong and permanent bond.

2. What are the advantages and disadvantages of oxyhydrogen welding?

Advantages

- Produces a clean and precise weld.

- Can be used to weld a wide variety of metals.

- Portable and easy to use.

Disadvantages

- Requires a lot of training and experience to master.

- Can be dangerous if not used properly.

- Can be more expensive than other welding methods.

3. What are the different types of oxyhydrogen welding torches?

There are two main types of oxyhydrogen welding torches: high-pressure and low-pressure.

- High-pressure torches use a high-pressure gas supply, which results in a hotter flame.

- Low-pressure torches use a low-pressure gas supply, which results in a cooler flame.

- The type of torch used depends on the thickness of the metal being welded.

4. What are the safety precautions that must be taken when using oxyhydrogen welding equipment?

- Wear proper safety gear, including gloves, goggles, and a welding helmet.

- Ensure that the welding area is well-ventilated.

- Keep the welding torch away from flammable materials.

- Never use the welding torch while under the influence of alcohol or drugs.

- Always follow the manufacturer’s instructions for operating the welding equipment.

5. What are the common defects that can occur in oxyhydrogen welds and how can they be prevented?

- Porosity: This is caused by gas bubbles becoming trapped in the weld metal. It can be prevented by ensuring that the welding area is clean and free of moisture.

- Cracking: This is caused by the weld metal cooling too quickly. It can be prevented by preheating the metal before welding and by allowing it to cool slowly after welding.

- Undercutting: This is caused by the weld metal melting the base metal. It can be prevented by using a smaller welding torch and by moving the torch more slowly.

- Overheating: This is caused by the weld metal becoming too hot. It can be prevented by using a smaller welding torch and by moving the torch more quickly.

6. What are the different applications of oxyhydrogen welding?

- Oxyhydrogen welding is used in a variety of applications, including:

- Automotive repair

- Appliance repair

- Jewelry making

- Art and sculpture

- Metal fabrication

7. What are the career opportunities for oxyhydrogen welders?

- Oxyhydrogen welders can work in a variety of industries, including:

- Automotive repair shops

- Appliance repair shops

- Fabrication shops

- Art studios

- Jewelry stores

8. What is the average salary of an oxyhydrogen welder?

The average salary of an oxyhydrogen welder depends on their experience, location, and industry.

- According to the U.S. Bureau of Labor Statistics, the median annual salary for welders, cutters, solderers, and brazers was $47,610 in May 2021.

- The lowest 10 percent earned less than $30,630, and the highest 10 percent earned more than $74,920.

9. What is the job outlook for oxyhydrogen welders?

The job outlook for oxyhydrogen welders is expected to be good over the next decade.

- According to the U.S. Bureau of Labor Statistics, employment of welders, cutters, solderers, and brazers is projected to grow 3 percent from 2021 to 2031.

- This growth is expected to be driven by increased demand for welding services in the construction, manufacturing, and transportation industries.

10. What are the skills and qualifications required to become an oxyhydrogen welder?

- Technical skills: Oxyhydrogen welders must have a strong understanding of the oxyhydrogen welding process, as well as the ability to operate oxyhydrogen welding equipment.

- Physical skills: Oxyhydrogen welders must have good hand-eye coordination and be able to work in a variety of positions.

- Communication skills: Oxyhydrogen welders must be able to communicate clearly with other workers and supervisors.

- Education and training: Oxyhydrogen welders typically receive on-the-job training or complete an apprenticeship program.

- Certification: Some oxyhydrogen welders choose to become certified by the American Welding Society (AWS).

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oxyhydrogen Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oxyhydrogen Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Oxyhydrogen Welders join metal parts using oxyhydrogen welding techniques. These welding specialists utilize hydrogen and oxygen gases to produce intense flames. They interpret blueprints and welding specifications to understand project requirements. Additionally, they examine welding surfaces for flaws, defects, and cleanliness prior to welding.

1. Welding Techniques

Oxyhydrogen Welders utilize various welding techniques, namely oxyhydrogen welding, torch brazing, and soldering. They calibrate welding equipment, set up welding stations, and position workpieces for welding.

- Ensure proper gas flow and pressure

- Select and adjust welding tips based on metal thickness

- Control welding speed and angle to achieve desired weld quality

2. Safety Compliance

Oxyhydrogen Welders prioritize safety in the workplace. They wear protective gear, including welding helmets, gloves, and aprons, to mitigate hazards like sparks, fumes, and heat. Welders follow established safety protocols and conduct regular equipment inspections to ensure a safe working environment.

- Inspect welding equipment for defects, leaks, or faulty connections

- Maintain a clean and organized work area free of tripping hazards

- Store and handle welding gases properly to prevent explosions or leaks

3. Quality Control

Quality control is paramount for Oxyhydrogen Welders. They inspect welded joints for defects, such as cracks, porosity, or incomplete fusion, using visual inspection techniques or non-destructive testing methods. Welders ensure welds meet specifications and industry standards, garantireing the structural integrity and functionality of the welded product.

- Interpret and adhere to welding codes and standards

- Perform visual inspections and non-destructive testing to detect weld defects

- Grind, re-weld, or repair defective welds to meet quality requirements

4. Collaboration and Communication

Oxyhydrogen Welders often collaborate with other professionals, such as engineers, project managers, and metal fabricators. They participate in project planning discussions, review design specifications, and provide feedback on welding feasibility and techniques.

- Read and interpret blueprints and technical drawings

- Discuss welding procedures and techniques with engineers and project managers

- Provide input on material selection, weld joint design, and quality control measures

Interview Tips

To prepare for an Oxyhydrogen Welder interview, you can follow these effective tips:

1. Research the Company and Industry

Demonstrating knowledge of the company and industry shows your interest and enthusiasm for the role. Research the company’s values, history, products or services, and industry trends. This knowledge will help you understand the company’s culture and how your skills and experience align with their needs.

- Visit the company’s website

- Read industry news and articles

- Connect with employees on LinkedIn

2. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers beforehand. This will help you feel more confident and articulate during the interview. Some common interview questions for Oxyhydrogen Welders include:

- Tell us about your experience with oxyhydrogen welding.

- What are the different types of welding joints you are familiar with?

- How do you ensure the quality of your welds?

3. Highlight Your Skills and Experience

Emphasize your welding skills and experience that are relevant to the job. Quantify your accomplishments whenever possible to demonstrate your impact. For example, instead of saying “I have experience in welding,” you could say “I have welded over 1000 joints using oxyhydrogen welding techniques, resulting in a 99% pass rate on quality inspections.”

4. Be Prepared to Discuss Safety

Safety is crucial in oxyhydrogen welding. Be prepared to discuss your safety knowledge and practices. You could mention your experience with using personal protective equipment, following safety protocols, and maintaining a safe work environment. Emphasize your commitment to safety and your understanding of the hazards associated with oxyhydrogen welding.

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest in the role. Prepare a few questions that demonstrate your curiosity and eagerness to learn more about the company, the position, or the industry. This could include questions about the company’s growth plans, the challenges and opportunities in the industry, or the training and development opportunities available to employees.

- What is the company’s vision for the future?

- What are the biggest challenges facing the industry right now?

- What opportunities are there for professional development?

Next Step:

Now that you’re armed with the knowledge of Oxyhydrogen Welder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Oxyhydrogen Welder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini