Are you gearing up for an interview for a Oxyacetylene Torch Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Oxyacetylene Torch Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

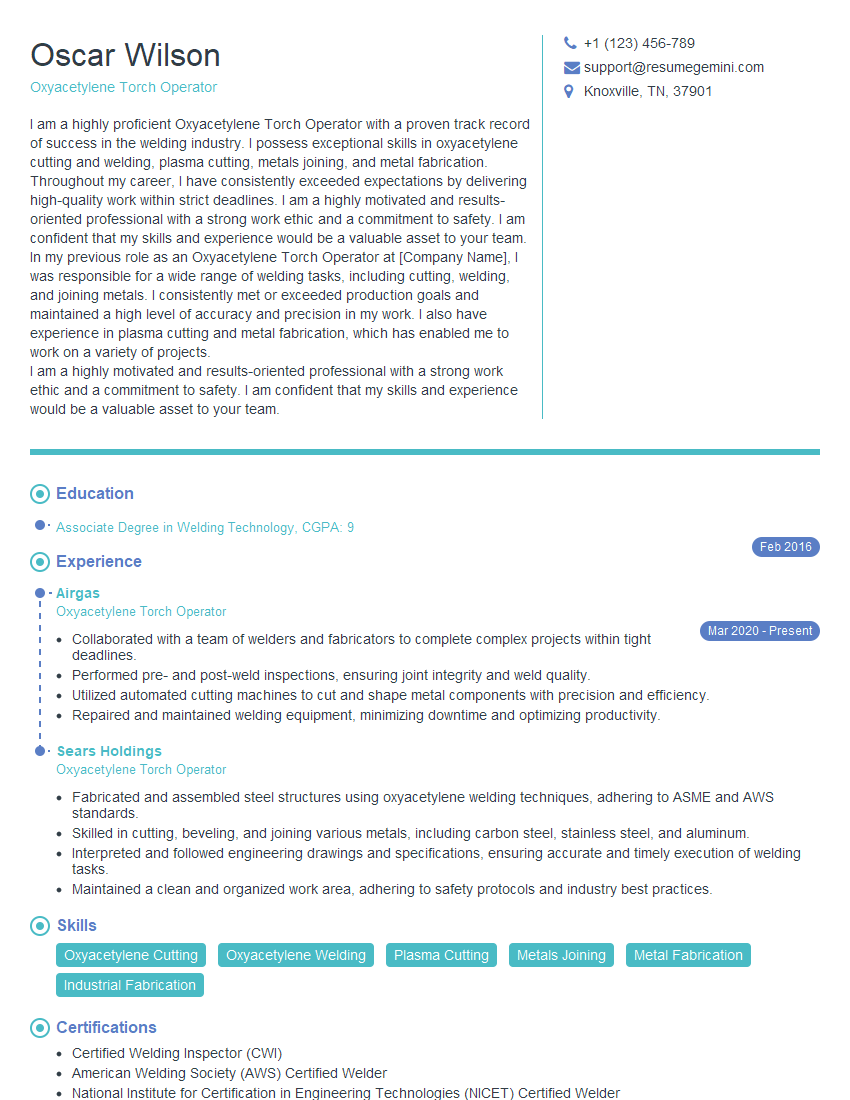

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oxyacetylene Torch Operator

1. Tell us about your experience as an Oxyacetylene Torch Operator?

- Started my career as an Oxyacetylene Torch Operator in [Year] at [Company Name].

- Worked on various projects involving cutting, welding, and brazing operations.

- Developed proficiency in handling different types of materials, including steel, stainless steel, aluminum, and copper.

- Maintained a clean and safe work environment, adhering to all safety regulations.

- Worked closely with other tradespeople to ensure project timelines were met.

2. Describe the safety measures you take when operating an oxyacetylene torch?

Pre-Operation Checks

- Inspect the torch, hoses, and connections for any damage.

- Ensure the work area is well-ventilated and free of flammable materials

- Wear appropriate personal protective equipment (PPE), including goggles, gloves, and flame-resistant clothing.

During Operation

- Maintain a safe distance from flammable objects.

- Keep the torch pointed away from the body.

- Never leave the torch unattended while ignited.

- Use a backfire preventer to prevent flashbacks.

Post-Operation

- Allow the torch to cool down before disassembling it.

- Store the torch and accessories in a safe and dry location.

3. What techniques do you use to ensure precise cutting with an oxyacetylene torch?

- Use a sharp cutting tip and maintain a proper distance from the workpiece.

- Control the speed and angle of the torch to achieve clean and accurate cuts.

- Use a straight edge or template to guide the torch for straight cuts.

- Practice and develop hand-eye coordination for precise control.

4. How do you adjust the oxyacetylene flame for different welding applications?

- Adjust the oxygen-to-acetylene ratio to achieve the desired flame characteristics.

- For cutting, a carburizing flame (excess acetylene) is used to create a reducing atmosphere.

- For welding, a neutral flame (equal parts oxygen and acetylene) is used to prevent oxidation.

- For brazing, a slightly oxidizing flame (excess oxygen) is used to promote bonding.

5. Describe the different types of oxyacetylene torch tips and their applications?

- Cutting Tips: Designed to provide a high-temperature flame for cutting metal.

- Welding Tips: Used for joining metal pieces, with different sizes and shapes for various applications.

- Brazing Tips: Have a smaller flame for precise heating and joining of non-ferrous metals.

- Heating Tips: Used for heating metal without cutting or welding.

6. Explain the process of flame hardening using an oxyacetylene torch?

- Clean and prepare the metal surface to be hardened.

- Use a neutral flame to heat the metal to a specific temperature.

- Rapidly quench the metal in water or oil to create a hard and wear-resistant surface.

7. How do you maintain and troubleshoot an oxyacetylene torch?

Maintenance

- Regularly clean the torch tips and hoses to prevent blockages.

- Inspect the regulators and gauges for proper operation.

- Lubricate moving parts as per manufacturer’s instructions.

Troubleshooting

- Torch Backfires: Caused by flashback, which can be resolved by adjusting the oxygen-to-acetylene ratio.

- Leaking Hoses: Replace damaged hoses immediately.

- Malfunctioning Regulators: Contact a qualified technician for repair or replacement.

8. What safety regulations and codes are applicable to oxyacetylene torch operation?

- NFPA 51: Standard for the Storage and Use of Oxygen and Fuel Gases.

- OSHA 29 CFR 1910.252: Welding, Cutting, and Brazing.

- Local building codes: May have specific requirements for oxyacetylene torch use.

9. How do you stay updated on the latest advancements in oxyacetylene torch technology?

- Attend industry conferences and trade shows.

- Read technical journals and articles.

- Consult with manufacturers and suppliers.

10. What sets you apart from other Oxyacetylene Torch Operators?

- Extensive experience in various oxyacetylene torch applications.

- Strong understanding of safety regulations and best practices.

- Proven ability to produce high-quality welds, cuts, and brazes.

- Excellent problem-solving and troubleshooting skills.

- Commitment to continuous learning and improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oxyacetylene Torch Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oxyacetylene Torch Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Oxyacetylene Torch Operator is a skilled professional who specializes in utilizing oxyacetylene torches for cutting, welding, soldering, and brazing various materials. The key job responsibilities of an Oxyacetylene Torch Operator typically include:

1. Equipment Operation

Safely operating oxyacetylene torches and related equipment, including regulators, hoses, and nozzles.

- Adjusting gas pressures and flow rates to achieve optimal flame characteristics

- Maintaining and repairing equipment as needed

2. Cutting and Welding Operations

Precisely cutting and welding metal components using oxyacetylene torches.

- Interpreting blueprints and work orders to determine cutting and welding specifications

- Setting up workstations and preparing materials for cutting or welding

3. Soldering and Brazing

Soldering and brazing metal components to join them without melting the base metal.

- Selecting the appropriate solder or brazing alloy for the job

- Applying flux and heating the metal to the desired temperature

4. Safety and Compliance

Adhering to safety protocols and regulations related to oxyacetylene torch operations.

- Wearing appropriate personal protective equipment (PPE)

- Ventilating work areas adequately

- Storing and handling oxyacetylene cylinders safely

Interview Tips

Preparing for an Oxyacetylene Torch Operator interview can significantly improve your chances of success. Here are some effective interview preparation tips to help you ace the interview:

1. Research the Company and Position

Take the time to research the company’s profile, industry, and specific job requirements. Understanding the company’s culture and the role’s expectations will help you tailor your answers and demonstrate your interest.

- Visit the company’s website for information on its history, values, and current projects

- Read industry publications and news articles to stay up-to-date on trends and best practices

2. Practice Your Answers

Prepare thoughtful responses to common interview questions, such as “Tell me about yourself” or “Why are you interested in this position?” Rehearsing your answers will help you deliver them confidently and effectively.

- Use the STAR method to structure your answers: Situation, Task, Action, Result

- Provide specific examples from your previous experience that demonstrate your skills and qualifications

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience during the interview. Focus on your proficiency in oxyacetylene torch operations, including cutting, welding, soldering, and brazing.

- Quantify your accomplishments whenever possible, using numbers and data to support your claims

- Mention any certifications or training programs you have completed to enhance your credibility

4. Ask Informed Questions

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the position. Prepare a few questions that show you have researched the company and the role.

- Inquire about the company’s safety protocols and training opportunities

- Ask about the growth potential and career advancement paths within the organization

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Oxyacetylene Torch Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.