Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Service Tech/Welder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Service Tech/Welder so you can tailor your answers to impress potential employers.

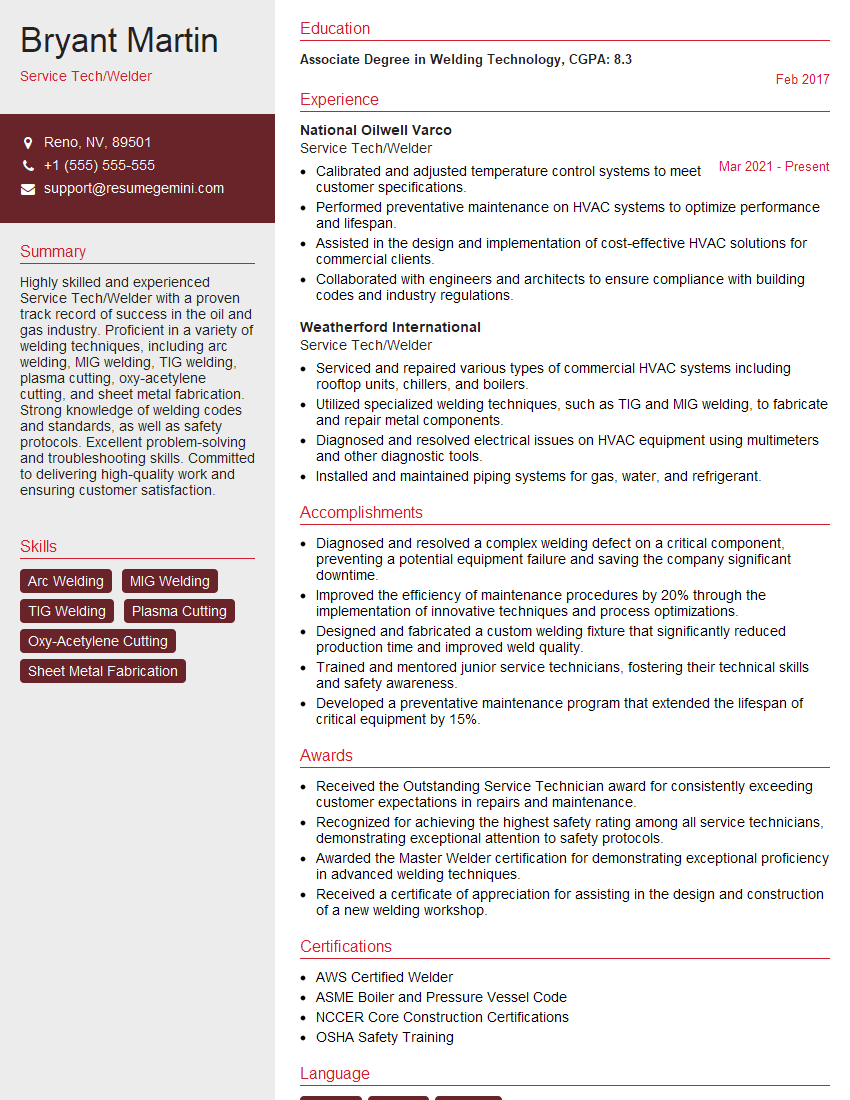

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Service Tech/Welder

1. Tell me about your experience with welding different types of metals?

In my previous role, I worked on a variety of welding projects involving different metals, including steel, stainless steel, aluminum, and titanium. I have extensive experience in various welding techniques, such as MIG, TIG, and stick welding. My expertise allows me to produce high-quality welds that meet the required specifications and industry standards.

2. Can you describe the process of welding a pressure vessel?

Safety Procedures

- Ensure proper ventilation and wear appropriate safety gear.

- Inspect the vessel for any damage or defects before welding.

Welding Procedures

- Prepare the vessel by cleaning and prepping the surfaces to be welded.

- Choose the appropriate welding technique and materials for the vessel’s specifications.

- Weld the vessel according to the specified welding procedures, ensuring proper penetration and fusion.

Inspection and Testing

- Inspect the welds visually and conduct non-destructive testing (e.g., dye penetrant or ultrasonic) to ensure weld quality.

- Perform pressure testing to verify the vessel’s integrity and ability to withstand the desired pressure.

3. What are the common defects that can occur in welding? How do you prevent and correct them?

- Porosity: Caused by gas entrapment. Prevented by using clean materials, proper shielding gas, and avoiding welding in drafty areas. Corrected by grinding and re-welding.

- Undercut: Excessive removal of base metal. Prevented by using proper welding parameters, maintaining a consistent electrode angle, and avoiding excessive heat input. Corrected by grinding and filling the undercut with weld metal.

- Cracking: Caused by excessive stress or embrittlement. Prevented by using preheating, stress-relieving techniques, and avoiding welding during extreme temperature changes. Corrected by removing the cracked section and re-welding.

4. How do you ensure the quality of your welds?

- Proper Preparation: Clean and prepare the surfaces to be welded, including removing rust, scale, and contaminants.

- Correct Technique: Use the appropriate welding technique, equipment, and materials for the specific application.

- Visual Inspection: Regularly inspect the welds for any visible defects, such as porosity, undercut, or cracks.

- Non-Destructive Testing: Conduct non-destructive testing (e.g., dye penetrant, ultrasonic) to detect any internal defects or imperfections.

- Compliance with Codes and Standards: Ensure that the welds meet the required industry codes and standards, such as AWS or ASME.

5. What types of welding equipment are you proficient in using?

- Manual Arc Welding: Stick welding (SMAW) and gas metal arc welding (GMAW)

- Semi-Automatic Welding: Flux-cored arc welding (FCAW) and metal inert gas welding (MIG)

- Automatic Welding: Gas tungsten arc welding (GTAW) and submerged arc welding (SAW)

6. How do you handle working in confined spaces?

- Safety First: Assess the space for potential hazards and ensure proper ventilation and lighting.

- Proper Equipment: Use compact equipment and specialized tools designed for confined spaces.

- Communication: Maintain clear communication with colleagues outside the confined space in case of emergencies.

- Ergonomics: Adopt comfortable and safe working postures to minimize strain and fatigue.

- Emergency Preparedness: Have an emergency plan in place and ensure that rescue equipment is readily accessible.

7. What is your experience with welding in different positions?

- Flat Position: Comfortable and allows for easy access to the weld joint.

- Horizontal Position: Requires more skill to maintain the molten weld pool and prevent slag inclusions.

- Vertical Position: Challenging due to gravity and requires specialized techniques to control the weld pool and prevent undercut.

- Overhead Position: Most difficult position, requiring excellent hand-eye coordination and the ability to work in awkward postures.

8. How do you stay updated with the latest welding techniques and advancements?

- Industry Publications: Read welding journals, magazines, and technical papers.

- Conferences and Seminars: Attend industry events to learn about new technologies and best practices.

- Online Resources: Utilize online platforms, forums, and webinars to connect with other welders and access valuable information.

- Certifications and Training: Pursue certifications and participate in training programs to enhance skills and knowledge.

9. Tell me about a time you faced a challenging welding project. How did you overcome the obstacles?

In a previous project, I encountered a situation where I had to weld a complex assembly in a confined space with limited accessibility. I had to devise a custom welding setup and utilize specialized tools to reach the weld joints. I also took extra precautions to ensure proper ventilation and safety measures in the confined space. Through careful planning, problem-solving, and meticulous execution, I was able to successfully complete the weld and meet the project requirements.

10. Why are you interested in working as a Service Tech/Welder in our company?

I am eager to join your company as a Service Tech/Welder due to its reputation for excellence in the industry. I am confident that my skills and experience in welding, troubleshooting, and customer service will be valuable assets to your team. I am particularly interested in the opportunity to contribute to your company’s commitment to providing high-quality repairs and installations to your clients.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Service Tech/Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Service Tech/Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Service Tech/Welder is responsible for a wide range of tasks related to the installation, maintenance, and repair of equipment and systems. This role requires a strong understanding of welding techniques, as well as the ability to work independently and as part of a team. Key job responsibilities include:

1. Equipment Installation and Maintenance

Installing and maintaining equipment and systems, including welding, fabrication, and piping.

- Inspecting equipment for signs of wear and tear, and making repairs as needed.

- Troubleshooting and resolving equipment malfunctions.

2. Welding

Performing a variety of welding tasks, including MIG, TIG, and stick welding.

- Interpreting welding blueprints and specifications.

- Setting up and operating welding equipment.

- Ensuring that welds meet all applicable safety and quality standards.

3. Fabrication and Piping

Fabricating and installing piping systems.

- Cutting, bending, and fitting pipes.

- Installing and connecting pipes to equipment and systems.

- Testing and inspecting piping systems for leaks.

4. Safety and Compliance

Ensuring that all work is performed in accordance with safety regulations and industry standards.

- Wearing appropriate safety gear, such as welding masks and gloves.

- Following all established safety procedures.

- Maintaining a clean and organized work area.

Interview Tips

Preparing for a Service Tech/Welder interview can be daunting, but by following these tips and tricks, you can increase your chances of success.

1. Research the Company and Position

Before the interview, take some time to learn about the company and the position you are applying for. This will help you answer questions about your qualifications and experience, and it will also show the interviewer that you are serious about the opportunity.

- Visit the company’s website to learn about their products, services, and culture.

- Read job descriptions and reviews to get an idea of what the position entails.

- Talk to people in your network who work for the company or who have knowledge of the industry.

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to structure your answers.

- Tell a story that highlights your skills and experience.

- Quantify your results whenever possible.

3. Bring a Portfolio of Your Work

If you have a portfolio of your welding work, bring it with you to the interview. This will give the interviewer a chance to see your skills firsthand. Make sure your portfolio is organized and well-presented.

4. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally for your interview. Arrive on time and be prepared to make a good impression.

5. Be Enthusiastic and Ask Questions

Show the interviewer that you are enthusiastic about the position. Ask questions about the company, the position, and the industry. This will show the interviewer that you are interested in learning more and that you are excited about the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Service Tech/Welder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!