Are you gearing up for a career in Torch Straightener and Heater? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Torch Straightener and Heater and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

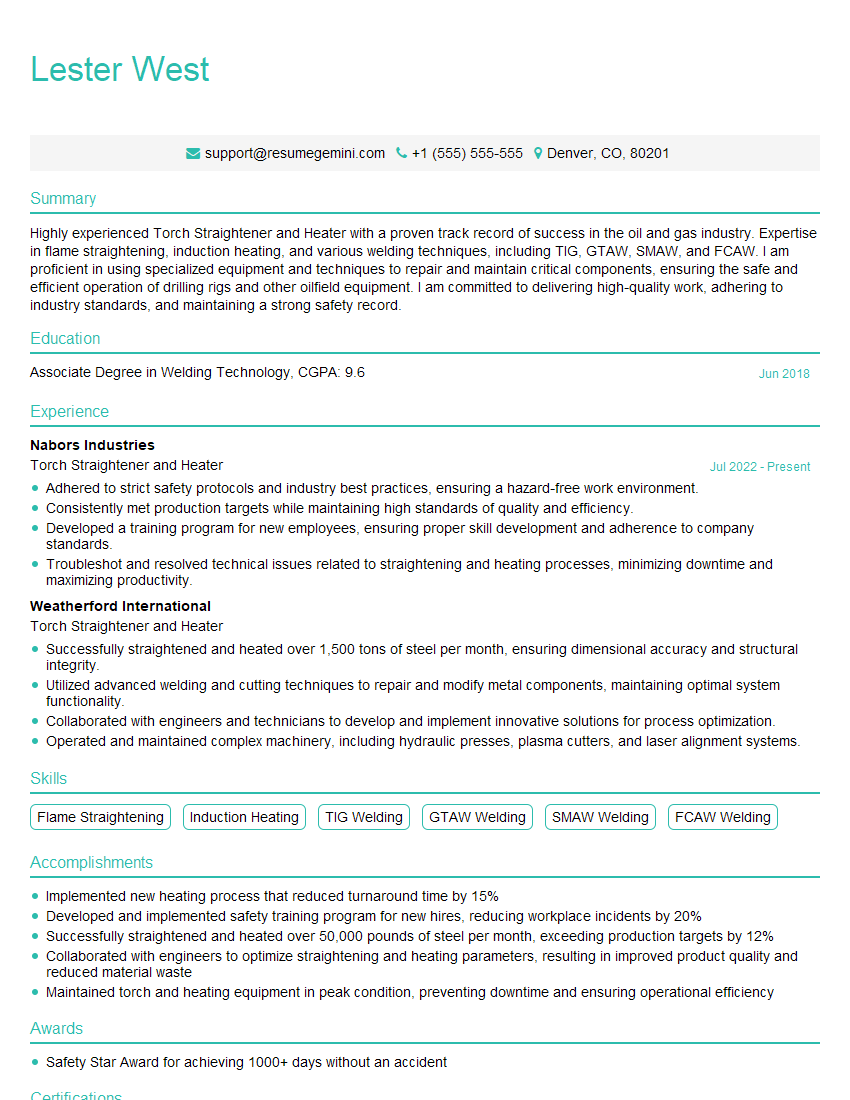

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Torch Straightener and Heater

1. Describe the steps involved in preparing a metal part for torch straightening?

- Inspect the part for any damage or defects.

- Clean the part to remove any dirt, grease, or other contaminants.

- Mark the areas that need to be straightened.

- Set up the torch and heat the metal to the appropriate temperature.

2. What are the different techniques used in torch straightening?

subheading of the answer

- Spot heating: This involves heating a small area of the metal to a high temperature to soften it and then straightening it with a hammer or other tool.

- Line heating: This involves heating a line along the length of the metal to a high temperature to soften it and then straightening it with a hammer or other tool.

subheading of the answer

- Progressive heating: This involves heating the metal gradually from one end to the other to soften it and then straightening it with a hammer or other tool.

3. What are the safety precautions that must be taken when using a torch for straightening?

- Wear appropriate safety gear, including gloves, safety glasses, and a fire-resistant apron.

- Use the torch in a well-ventilated area.

- Keep the torch away from flammable materials.

- Never point the torch at anyone.

4. What are the common mistakes that can be made when using a torch for straightening?

- Overheating the metal.

- Not heating the metal evenly.

- Using the wrong technique for the job.

- Not taking proper safety precautions.

5. What are the different types of torches that can be used for straightening?

- Propane torches

- Acetylene torches

- Oxy-acetylene torches

- Plasma torches

6. What is the difference between a torch and a heater?

- A torch produces a flame that is used to heat metal to a high temperature.

- A heater produces a stream of hot air that is used to heat metal to a lower temperature.

- Torches are used for straightening and bending metal, while heaters are used for preheating metal before welding or brazing.

7. What are the different types of heaters that can be used for straightening?

- Propane heaters

- Electric heaters

- Infrared heaters

8. What are the safety precautions that must be taken when using a heater for straightening?

- Wear appropriate safety gear, including gloves, safety glasses, and a fire-resistant apron.

- Use the heater in a well-ventilated area.

- Keep the heater away from flammable materials.

- Never point the heater at anyone.

9. What are the common mistakes that can be made when using a heater for straightening?

- Overheating the metal.

- Not heating the metal evenly.

- Using the wrong technique for the job.

- Not taking proper safety precautions.

10. What are the advantages of using a heater for straightening?

- Heaters can be used to heat metal to a more precise temperature than torches.

- Heaters are less likely to damage the metal than torches.

- Heaters are easier to use than torches.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Torch Straightener and Heater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Torch Straightener and Heater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Torch Straightener and Heater is responsible for straightening and heat-treating metal parts using a torch. Their key responsibilities include:

1. Preparing Parts for Straightening

Measuring and marking parts to determine the required amount of straightening

2. Heating and Straightening Parts

Using a torch to heat metal parts to soften them

Applying force to straighten parts using a variety of tools, such as hammers, anvils, and jigs

Cooling parts rapidly to harden them and retain their new shape

3. Inspecting Straightened Parts

Ensuring that straightened parts meet specifications

Identifying and correcting any defects

4. Maintaining Equipment

Cleaning and maintaining torches and other equipment

Performing minor repairs as needed

Interview Tips

To prepare for an interview for a Torch Straightener and Heater position, it is important to:

1. Research the Company

Learn about the company’s products, services, and culture

This will show the interviewer that you are interested in the position and that you have taken the time to learn about the company.

2. Practice Your Answers to Common Interview Questions

Some common interview questions that you may be asked include:

- Tell me about your experience as a Torch Straightener and Heater.

- What are your strengths and weaknesses?

- Why are you interested in this position?

- What are your salary expectations?

It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Bring Examples of Your Work

If possible, bring examples of your work to the interview

This will give the interviewer a chance to see your skills and abilities firsthand.

4. Be Prepared to Talk About Your Safety Knowledge

As a Torch Straightener and Heater, it is important to have a strong understanding of safety procedures

Be prepared to talk about your safety knowledge and experience during the interview.

5. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview

This shows the interviewer that you are serious about the position and that you are respectful of their time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Torch Straightener and Heater interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.