Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Welder and Fitter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

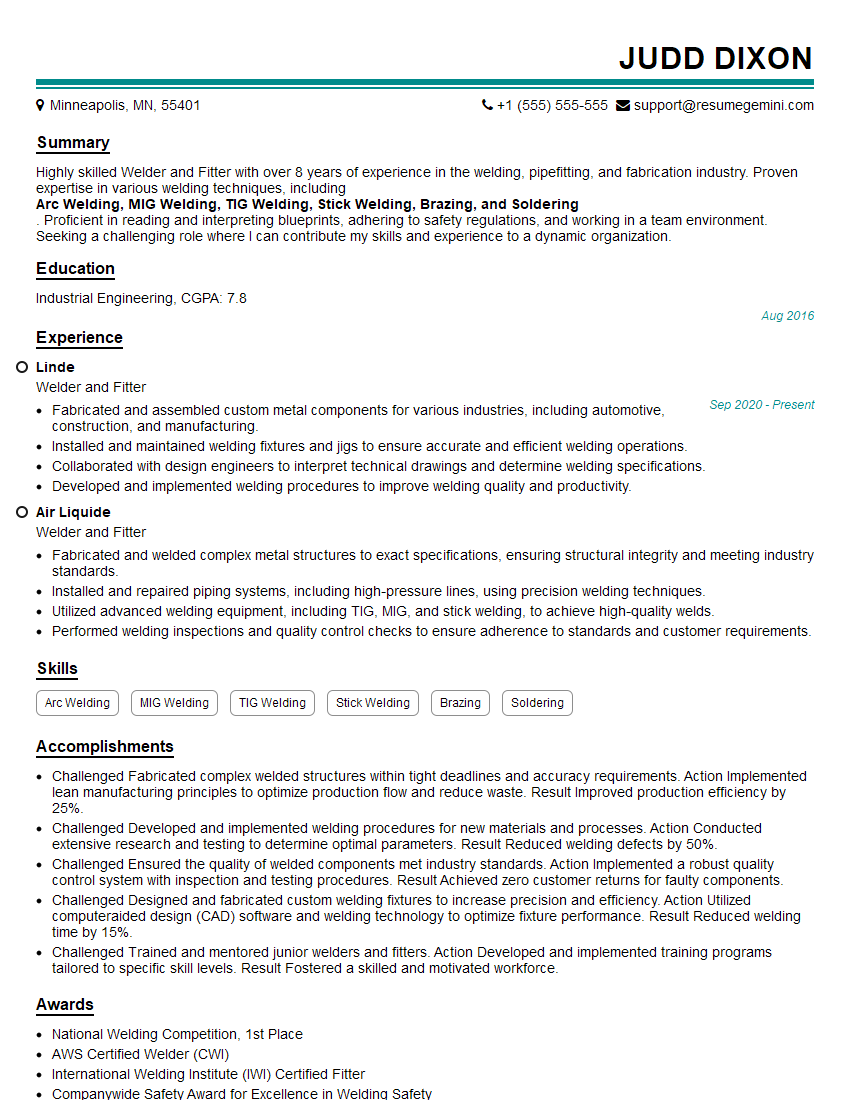

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Welder and Fitter

1. What welding processes are you proficient in?

- Gas Tungsten Arc Welding (GTAW) or Tungsten Inert Gas (TIG) welding

- Gas Metal Arc Welding (GMAW) or Metal Inert Gas (MIG) welding

- Shielded Metal Arc Welding (SMAW) or Stick welding

2. What types of joints can you weld?

Butt joints

- Square butt joint

- Bevel butt joint

- V-groove butt joint

Edge joints

- Square edge joint

- Bevel edge joint

- V-groove edge joint

3. What are the different types of welding defects and how do you avoid them?

- Porosity: caused by entrapped gases, avoid by using clean materials and shielding gas.

- Cracking: caused by stresses or lack of fusion, avoid by using proper welding techniques and preheating the metal.

- Undercut: caused by excessive heat input, avoid by using proper welding parameters and techniques.

4. What safety precautions should be taken when welding?

- Wear appropriate protective gear (helmet, gloves, apron)

- Ensure proper ventilation to avoid inhaling fumes

- Keep the work area clean and free of flammable materials

5. What is the difference between a fitter and a welder?

- Fitter: Prepares and aligns metal components for welding, ensures proper fit and alignment.

- Welder: Joins metal components using welding techniques, ensures proper weld quality.

6. What are the key responsibilities of a fitter?

- Inspect and measure metal components

- Cut, shape, and assemble metal components

- Align and tack weld components

7. What are the key responsibilities of a welder?

- Select and prepare welding equipment

- Join metal components using appropriate welding techniques

- Inspect welds for quality and defects

8. What is the difference between a welding procedure specification (WPS) and a welding procedure qualification record (WPQR)?

- WPS: Outlines the welding parameters and procedures to be used for a specific welding application.

- WPQR: Documents the results of welding tests performed to qualify a WPS.

9. What are the different types of welding codes and standards?

- American Welding Society (AWS)

- American Society of Mechanical Engineers (ASME)

- International Organization for Standardization (ISO)

10. What is your experience with welding in different positions?

- Flat

- Horizontal

- Vertical

- Overhead

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Welder and Fitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Welder and Fitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Welders and Fitters are responsible for joining and assembling various metal components to create structures, equipment, and other objects. Their key responsibilities include:

1. Welding and Fabrication

Welders and Fitters use different welding techniques to join metal components, ensuring proper penetration and strength. They operate welding machines, interpret blueprints, and follow precise specifications to create complex structures and repair damaged parts.

2. Fitting and Assembly

They fit and assemble metal components using hand tools, power tools, and precision measuring instruments. They ensure that components align correctly and meet design specifications before welding or bonding them together.

3. Cutting and Shaping

Welders and Fitters cut and shape metal parts using plasma cutters, oxy-acetylene torches, and other tools. They follow precise dimensions and ensure that the cut and shaped pieces meet the required specifications.

4. Inspection and Testing

They inspect and test welded joints and assembled structures to ensure compliance with industry standards and safety regulations. They use visual inspections, non-destructive testing methods, and other techniques to identify any defects or areas of concern.

Interview Tips

Preparing thoroughly for a Welder and Fitter interview can significantly increase your chances of success. Here are some tips and hacks to help you ace the interview:

1. Research the Company and Position

Take the time to learn about the company’s industry, products, and culture. Research the specific Welder and Fitter position you are applying for, understanding its responsibilities and requirements.

2. Highlight Your Skills and Experience

Emphasize your welding and fitting skills, including the specific techniques and equipment you are proficient in. Showcase your ability to read blueprints, interpret specifications, and adhere to industry standards.

3. Prepare Technical Questions

Expect to answer technical questions related to welding techniques, materials, and safety procedures. Be prepared to demonstrate your knowledge of different types of welds, welding equipment, and industry best practices.

4. Showcase Your Problem-Solving Abilities

Welders and Fitters often encounter challenges on the job. Prepare examples of how you have solved problems related to fitting, welding, or other aspects of the job. Highlight your analytical and critical thinking skills.

5. Emphasize Safety and Quality

Welding and Fitting involves potential hazards. Emphasize your commitment to safety and your adherence to industry regulations. Additionally, highlight your attention to detail and your ability to produce high-quality work that meets specifications.

6. Prepare Questions for the Interviewer

Asking thoughtful questions during the interview shows your engagement and interest in the position. Prepare questions about the company’s projects, training opportunities, or the specific challenges of the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Welder and Fitter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!