Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Welder-Assembler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Welder-Assembler so you can tailor your answers to impress potential employers.

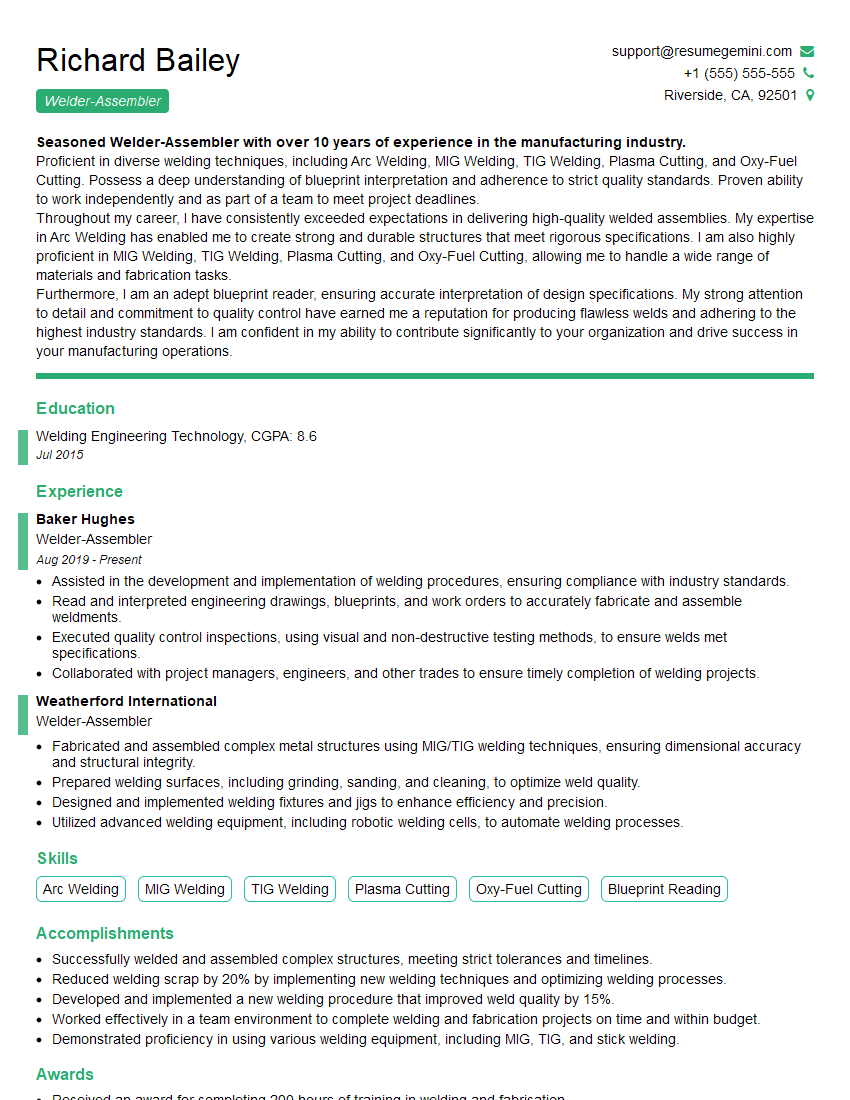

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Welder-Assembler

1. What are the different types of welding processes you have experience with?

- Arc Welding (SMAW, GMAW, GTAW)

- Resistance Welding (Spot Welding, Seam Welding)

- Laser Welding

2. Describe the steps involved in preparing a workpiece for welding.

Cleaning the Surface

- Remove dirt, oil, and rust

- Use solvents, abrasives, or brushes

Joint Preparation

- Edge preparation (beveling, chamfering)

- Gap measurement and adjustment

3. What welding joints are commonly used in structural fabrication?

- Butt Joint

- Edge Joint

- Corner Joint

- T-Joint

- Lap Joint

4. How do you ensure the quality of your welds?

- Visual Inspection

- Non-Destructive Testing (NDT)

- Dye Penetrant Testing

- Radiographic Testing

- Stress Testing

5. What are the safety precautions you take while welding?

- Protective Clothing (gloves, helmet, coverall)

- Ventilation

- Eye Protection

- Fire Extinguisher

- Hot Work Permit

6. How do you handle welding in different positions (flat, vertical, horizontal)?

- Flat Position: Use gravity

- Vertical Position: Use weaving techniques

- Horizontal Position: Use backhand or forehand technique

7. What types of materials have you welded before?

- Steel (Mild Steel, Stainless Steel)

- Aluminum

- Cast Iron

- Copper

8. How do you read and interpret welding blueprints and specifications?

- Identify symbols, dimensions, and tolerances

- Understand welding processes, materials, and joint types

- Follow safety instructions and quality standards

9. What are the troubleshooting steps you take if a weld is not meeting specifications?

Identify the Issue

- Visual Inspection

- Non-Destructive Testing

Determine the Cause

- Incorrect setup

- Equipment malfunction

- Material defects

Corrective Actions

- Adjust parameters

- Repair or replace equipment

- Use different welding techniques

10. How do you stay up-to-date on the latest welding techniques and technologies?

- Attend industry conferences and workshops

- Read technical journals and articles

- Consult with manufacturers and suppliers

- Take online courses or certification programs

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Welder-Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Welder-Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Welder-Assembler is responsible for performing various welding and assembly tasks in a manufacturing environment. Their duties include:

1. Welding and Joining Components

Using various welding techniques (e.g., MIG, TIG, arc welding) to join metal components and fabricate assemblies.

- Reading and interpreting blueprints and work orders to determine welding specifications and assembly instructions.

- Setting up and operating welding equipment, including grinders, cutters, and welding machines.

2. Assembly and Fitting

Assembling components into complete products, including fastening, riveting, and bolting.

- Ensuring that components fit together correctly and meet quality standards.

- Making adjustments to parts as needed to achieve proper fit and alignment.

3. Quality Inspection

Inspecting welded joints and assemblies to ensure they meet specifications and industry standards.

- Using measuring tools, gauges, and other inspection equipment to verify dimensions, weld integrity, and overall quality.

- Identifying and correcting any defects or non-conformances.

4. Maintenance and Repair

Performing routine maintenance and repairs on welding equipment and assembly line machinery.

- Replacing worn or damaged parts, cleaning and calibrating equipment.

- Troubleshooting and resolving equipment malfunctions to minimize downtime.

Interview Tips

Preparing for an interview for a Welder-Assembler position requires research, practice, and a well-organized strategy. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Before the interview, take the time to research the company you’re applying to and the industry they operate in. This will give you a better understanding of their products, services, culture, and the specific requirements of the Welder-Assembler role.

- Visit the company website to learn about their history, mission, and values.

- Check industry news and publications to stay up-to-date on trends and best practices.

2. Practice Your Welding Skills

As a Welder-Assembler, it’s essential to demonstrate your technical proficiency during the interview. If possible, practice your welding skills beforehand to ensure you can confidently perform welding techniques and answer questions related to your expertise.

- Set up a practice area in your garage or other suitable location.

- Gather the necessary materials, including scrap metal, welding equipment, and safety gear.

3. Prepare for Technical Questions

Anticipate technical questions related to welding processes, equipment, and quality standards. Review the job description and research common welding techniques to prepare your answers.

- Be familiar with different types of welding joints (e.g., butt joint, T-joint, corner joint).

- Understand the properties of various metals and how they affect welding.

4. Emphasize Safety and Quality

Safety is paramount in welding and assembly operations. Show that you prioritize safety by highlighting your knowledge of safety protocols and your commitment to following them.

- Demonstrate your understanding of personal protective equipment (PPE) and how it prevents workplace accidents.

- Explain your approach to quality control and your experience in identifying and correcting defects.

Next Step:

Now that you’re armed with the knowledge of Welder-Assembler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Welder-Assembler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini