Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Welder-Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

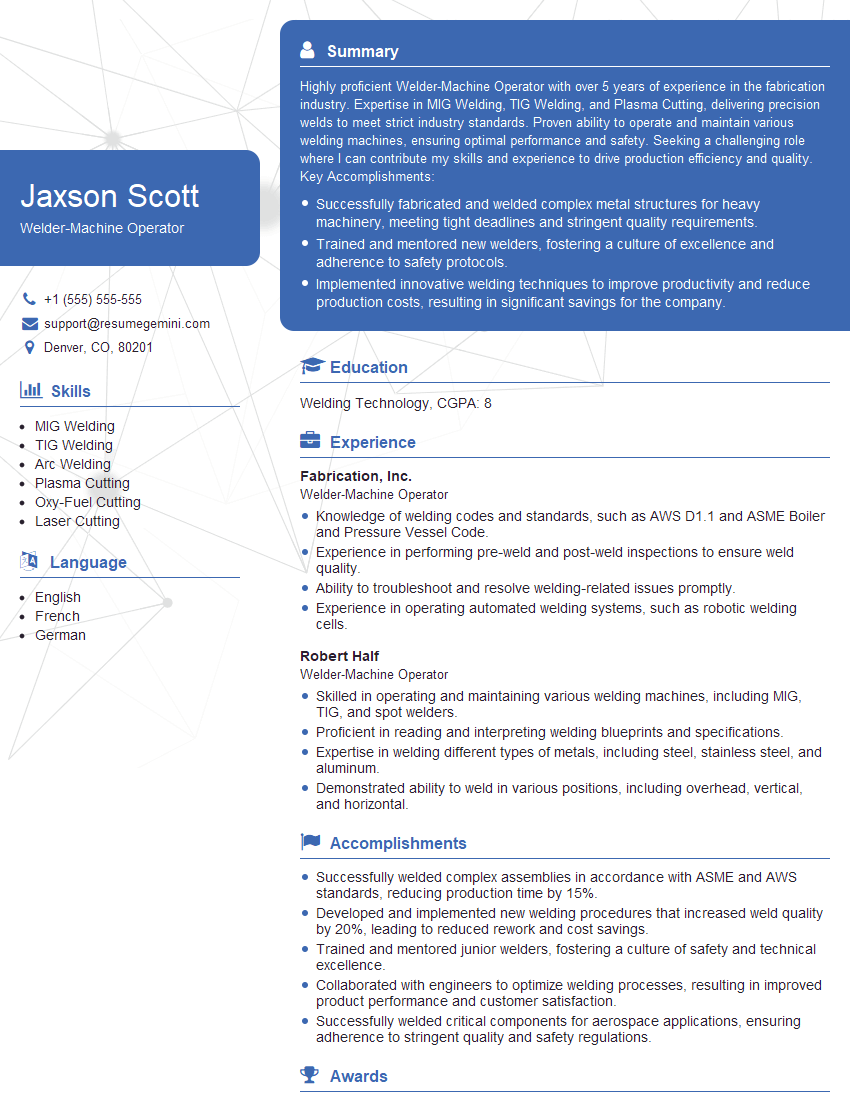

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Welder-Machine Operator

1. Describe the different types of welding processes you are familiar with and explain their advantages and disadvantages.

- Arc welding (SMAW, GMAW, FCAW, GTAW): Uses an electric arc to create a weld. It is versatile and can be used for a variety of materials, but it can be slower and less precise than other methods.

- Laser welding: Uses a laser beam to create a weld. It is faster and more precise than arc welding, but it can be more expensive and requires specialized equipment.

- Resistance welding: Uses heat and pressure to create a weld. It is fast and efficient, but it is limited to certain types of materials.

2. What are the most important factors to consider when selecting the correct welding process for a given application?

- Material thickness: The thickness of the material will determine the amount of heat and penetration required for welding.

- Material type: The type of material will also affect the welding process. Some materials, such as aluminum, require special welding techniques.

- Joint design: The design of the joint will also affect the welding process. Butt joints, for example, require a different welding technique than lap joints.

- Production rate: The required production rate will also affect the welding process. Some processes, such as laser welding, are faster than others.

3. What are the different types of welding defects and how can they be prevented?

- Porosity: Caused by gas bubbles trapped in the weld. Can be prevented by using a shielding gas or by welding in a vacuum.

- Inclusions: Caused by foreign objects trapped in the weld. Can be prevented by cleaning the weld area before welding.

- Cracking: Caused by stresses in the weld. Can be prevented by using the proper welding technique and by preheating the weld area.

- Undercut: Caused by the weld metal not penetrating the base metal. Can be prevented by using the proper welding technique and by using a filler metal that is compatible with the base metal.

4. What are the different types of welding equipment and how do they work?

- Welding machines: Provide the electrical power needed for welding. They can be either AC or DC, and they come in a variety of sizes and types.

- Welding torches: Direct the welding arc to the weld area. They are made of a variety of materials, including copper, brass, and steel.

- Filler metals: Provide the material that is added to the weld joint. They can be made of a variety of materials, including steel, aluminum, and stainless steel.

- Shielding gases: Protect the weld area from the atmosphere. They can be either inert gases, such as argon and helium, or active gases, such as carbon dioxide and oxygen.

5. What are the safety precautions that must be taken when welding?

- Wear appropriate safety gear, including a welding helmet, gloves, and protective clothing.

- Ventilate the work area to remove welding fumes.

- Keep the work area clean and free of tripping hazards.

- Never weld on a live circuit.

- Always inspect the welding equipment before use.

6. What are the different types of welding codes and standards?

- American Welding Society (AWS): Develops welding codes and standards for the United States.

- International Organization for Standardization (ISO): Develops welding codes and standards for international use.

- American Society of Mechanical Engineers (ASME): Develops welding codes and standards for pressure vessels and piping systems.

- American Petroleum Institute (API): Develops welding codes and standards for the oil and gas industry.

7. How do you stay up-to-date on the latest welding technologies and techniques?

- Read welding magazines and journals.

- Attend welding conferences and trade shows.

- Take welding courses and workshops.

- Network with other welders.

8. What do you think are the most important qualities of a successful welder?

- Attention to detail

- Manual dexterity

- Problem-solving skills

- Safety consciousness

- Commitment to quality

9. What is your experience with welding different types of materials?

- Steel

- Aluminum

- Stainless steel

- Cast iron

- Copper

10. What is your experience with welding different types of joints?

- Butt joints

- Edge joints

- Lap joints

- T-joints

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Welder-Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Welder-Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

## Key Job Responsibilities A Welder-Machine Operator is a skilled professional responsible for operating welding machines to join metal components together. They ensure the accuracy and quality of welds, adhering to safety regulations and industry standards. Core responsibilities include: ### 1. Welding Equipment Operation – Setup and operate welding machines, including TIG, MIG, and stick welding equipment – Adjust and calibrate welding parameters like amperage, voltage, and wire feed speed – Position workpieces and guide welding torch to achieve desired weld characteristics ### 2. Fabrication and Assembly – Interpret blueprints and welding instructions to understand project requirements – Prepare and assemble metal components using welding, grinding, and cutting techniques – Fabricate metal structures, fixtures, and equipment according to specifications ### 3. Quality Assurance – Inspect and test weld quality according to established standards – Identify and correct weld defects, ensuring structural integrity and reliability – Maintain welding equipment and work area to ensure safety and efficiency ### 4. Safety Compliance – Adhere to all applicable safety regulations and industry standards – Wear appropriate protective gear, including gloves, helmets, and fire-resistant clothing – Operate welding machines in a safe and responsible manner, preventing accidents or injuriesInterview Preparation Tips

To ace a Welder-Machine Operator job interview, follow these essential preparation tips: ### 1. Research the Company and Position – Learn about the company’s products or services, company culture, and industry position. – Thoroughly review the job description, noting key responsibilities and qualifications. – Identify areas where your skills and experience align with the company’s needs. ### 2. Practice Common Interview Questions – Prepare answers to common interview questions about your welding experience, technical skills, and safety practices. – Practice STAR (Situation, Task, Action, Result) method to provide concise and relevant examples. – Example: “Describe a time when you encountered a welding defect. How did you identify and resolve the issue?” ### 3. Highlight Your Welding Skills – Emphasize your proficiency in different welding techniques and the types of materials you’ve worked with. – Quantify your experience with specific numbers (e.g., “Completed over 500 TIG welds on stainless steel”). – Showcase your ability to weld to precise specifications and meet industry standards. ### 4. Demonstrate Safety Consciousness – Clearly articulate your commitment to safety in the workplace. – Discuss your understanding of applicable safety regulations and your adherence to them. – Provide examples of how you prioritize safety in your welding practices. ### 5. Be Enthusiastic and Prepared to Ask Questions – Show genuine interest in the position and the company. – Prepare questions that demonstrate your eagerness to learn more and contribute your skills. – Example: “Can you elaborate on the company’s welding technology and its application in current projects?”Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Welder-Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!