Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Electrical Solderer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

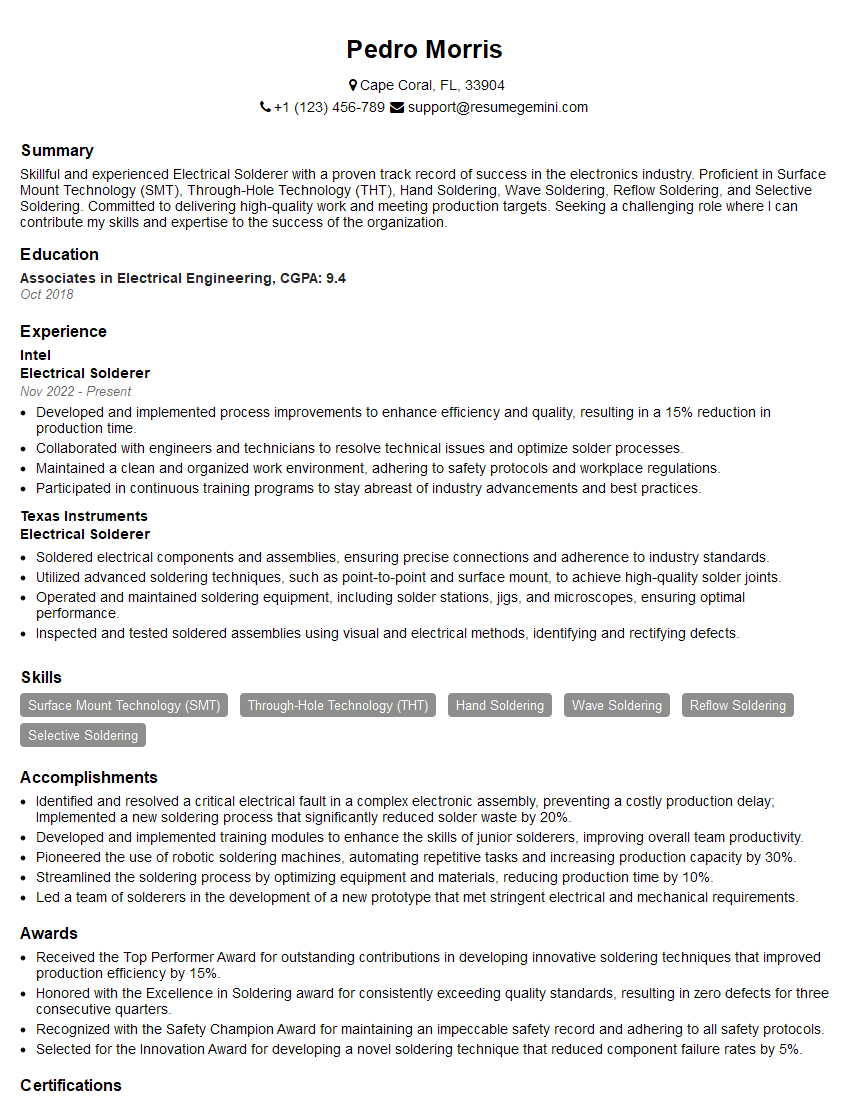

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electrical Solderer

1. What are the different types of soldering techniques used in electrical work?

- Through-hole soldering

- Surface mount soldering

- Wave soldering

- Reflow soldering

- Hand soldering

2. What are the safety precautions that should be taken when soldering?

Eye protection

- Wear safety glasses to protect your eyes from flying solder and flux.

Hand protection

- Wear gloves to protect your hands from heat and solder burns.

Ventilation

- Work in a well-ventilated area to avoid inhaling solder fumes.

3. What are the key factors that affect the quality of a soldered joint?

- Cleanliness of the surfaces to be joined

- Proper application of flux

- Correct soldering iron temperature

- Sufficient solder is applied

- Proper cooling rate

4. What are the common defects that can occur in soldered joints, and how can they be prevented?

Cold solder joints

- Caused by insufficient heat or solder

- Prevention: Use a hotter soldering iron or apply more solder

Dry solder joints

- Caused by lack of flux

- Prevention: Apply flux to the surfaces to be joined

Bridging

- Caused by too much solder

- Prevention: Use less solder or a smaller soldering iron tip

5. What are the different types of solder and their applications?

Lead-based solder

- Strong and ductile

- Used in high-stress applications

Lead-free solder

- More environmentally friendly

- Used in consumer electronics and other applications where lead is restricted

Silver-based solder

- High melting point

- Used in high-temperature applications

6. What are the different types of soldering equipment and their uses?

Soldering irons

- Handheld tools used to heat solder

- Available in different wattages and tip shapes

Soldering stations

- More advanced soldering systems that include a soldering iron, temperature control, and other features

- Often used in production environments

Soldering guns

- High-power soldering tools that are triggered by pulling a trigger

- Used for heavy-duty soldering applications

7. What are the different types of flux and their applications?

Rosin core solder

- Contains flux in the core of the solder wire

- Used for general-purpose soldering

Liquid flux

- Applied separately to the surfaces to be joined

- Available in different formulations for different applications

Paste flux

- Similar to liquid flux but thicker

- Used for surface mount soldering and other applications where flux control is critical

8. What are the different types of desoldering techniques and their advantages and disadvantages?

Manual desoldering

- Uses a desoldering braid or wick to remove solder

- Advantages: Simple and inexpensive

- Disadvantages: Time-consuming and can damage components if not done carefully

Vacuum desoldering

- Uses a vacuum pump to remove solder

- Advantages: Fast and efficient

- Disadvantages: Expensive and can be difficult to use on small components

Hot air desoldering

- Uses hot air to melt solder

- Advantages: Fast and efficient

- Disadvantages: Can damage components if not done carefully

9. What are the different types of solder joints and their applications?

Through-hole solder joint

- Used to connect components to a printed circuit board (PCB)

Surface mount solder joint

- Used to connect components to the surface of a PCB

Wire-to-wire solder joint

- Used to connect two wires together

10. What are the quality control procedures that can be used to ensure the quality of soldered joints?

Visual inspection

- Used to check for defects such as cold solder joints, dry solder joints, and bridging

Electrical testing

- Used to check for continuity and other electrical properties

X-ray inspection

- Used to check for internal defects such as voids and cracks

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electrical Solderer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electrical Solderer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electrical Solderers play a critical role in the electronic manufacturing industry by creating electrical connections between components using solder and a soldering iron. Their key responsibilities include:

1. Soldering Electrical Components

Precision soldering of electronic components onto printed circuit boards (PCBs) using soldering iron or wave soldering machine, ensuring secure and reliable connections.

- Identifying and selecting appropriate solder alloys and flux for specific materials and applications.

- Preparing and cleaning components and PCBs to create optimal soldering surfaces.

2. Inspecting Soldered Connections

Thorough examination of soldered connections using visual inspection techniques and specialized equipment to verify their quality and conformance to specifications.

- Identifying and correcting any defects or inconsistencies in solder joints.

- Adhering to industry standards and quality control measures.

3. Troubleshooting and Repairing Electrical Assemblies

Diagnosing and resolving electrical issues within soldered assemblies.

- Identifying faulty connections, shorts, or other defects.

- Replacing or repairing damaged components or traces.

4. Maintaining Equipment and Workspace

Ensuring the proper functioning and calibration of soldering equipment, including soldering irons, wave soldering machines, and inspection devices.

- Maintaining a clean and organized workspace to promote efficiency and safety.

- Performing routine maintenance and troubleshooting to prevent equipment failures.

Interview Tips

To ace an interview for an Electrical Solderer position, it’s essential to prepare thoroughly and showcase your skills and experience effectively. Here are some tips to help you succeed:

1. Research the Company and Position

Gather information about the company’s products, industry, and company culture. Familiarize yourself with the specific job requirements and responsibilities.

- Visit the company’s website, LinkedIn page, and other online resources.

- Read industry publications and articles to stay updated on best practices and technologies.

2. Highlight Your Soldering Skills and Experience

Demonstrate your proficiency in various soldering techniques, including hand soldering, wave soldering, and reflow soldering. Quantify your experience with specific examples.

- Describe the types of electronic assemblies you have worked on and the soldering standards you followed.

- Provide examples of projects where you successfully identified and resolved soldering defects.

3. Emphasize Quality and Attention to Detail

Electrical Solderers are responsible for ensuring the quality and reliability of electrical connections. Highlight your attention to detail and commitment to meeting or exceeding industry standards.

- Explain your inspection process and how you ensure the accuracy and integrity of soldered joints.

- Discuss your experience in adhering to quality control guidelines and implementing corrective actions.

4. Show Your Team Skills and Adaptability

Electrical Solderers often work in team environments and must be able to adapt to changing requirements. Emphasize your ability to collaborate effectively and your willingness to learn new technologies.

- Share examples of how you have contributed to team projects and supported your colleagues.

- Describe your experience in working with engineers, technicians, and other professionals.

5. Prepare for Technical Questions

Interviewers may ask technical questions to assess your knowledge and skills. Be prepared to discuss soldering techniques, materials, equipment calibration, and troubleshooting methods.

- Review soldering principles, including solder alloy selection, flux usage, and joint design.

- Familiarize yourself with the different types of soldering equipment and their applications.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Electrical Solderer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Electrical Solderer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.