Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Solderer-Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

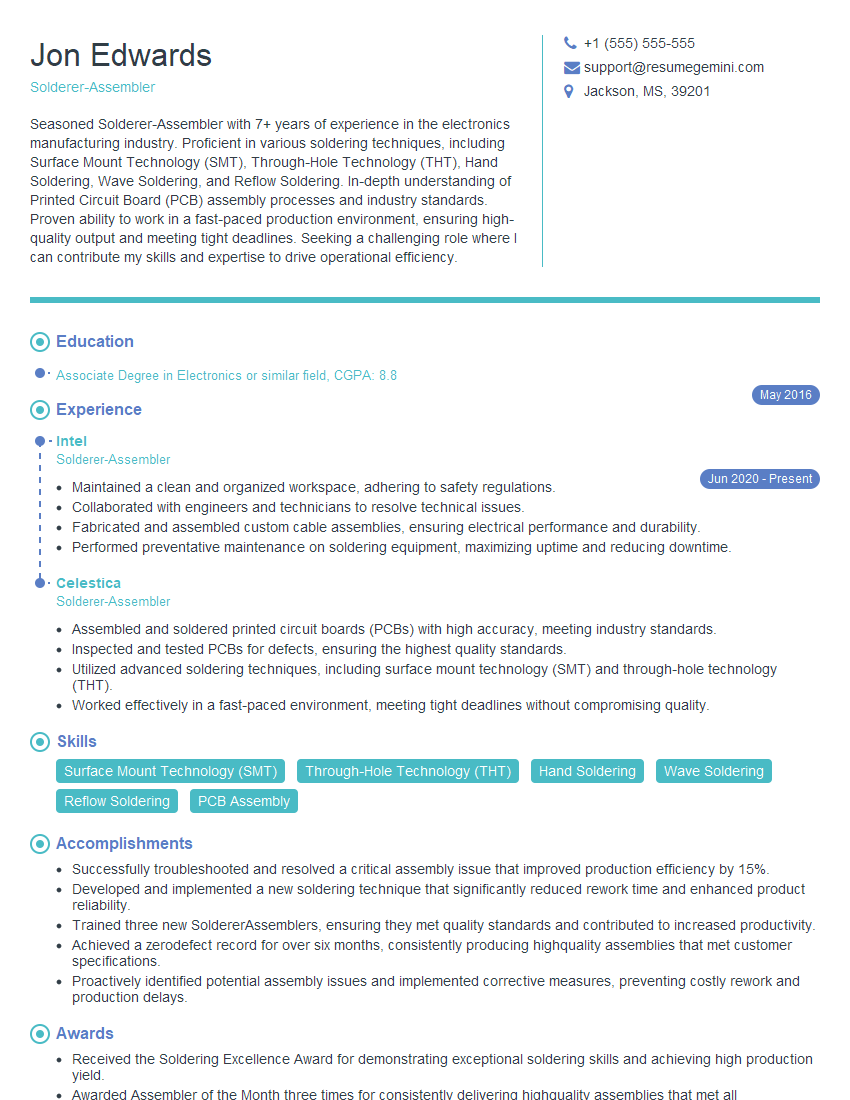

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Solderer-Assembler

1. What are your experiences in soldering and assembling electronic components?

Here are some of my experiences in soldering and assembling electronic components:

- I have over 5 years of experience in soldering and assembling electronic components for various industries, including consumer electronics, automotive, and medical devices.

- I am proficient in a wide range of soldering techniques, including hand soldering, wave soldering, and reflow soldering.

- I am also experienced in assembling electronic components using both manual and automated processes.

2. What are the different types of solder joints?

Types of Solder Joints

- Butt joint

- Edge joint

- Lap joint

- T-joint

- Mitre joint

Factors Affecting the Strength of a Solder Joint

- Type of solder joint

- Solder alloy

- Soldering technique

- Surface preparation

- Component design

3. What are the common defects in soldered joints?

There are many common defects in soldered joints, some of the most common include:

- Solder bridges

- Cold solder joints

- Open solder joints

- Solder balls

- Solder icicles

4. How do you inspect soldered joints?

I inspect soldered joints using a variety of methods, including:

- Visual inspection

- Electrical testing

- X-ray inspection

- Ultrasonic inspection

5. What are the safety precautions that must be taken when soldering?

When soldering, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment, including safety glasses, gloves, and a lab coat.

- Work in a well-ventilated area.

- Use a soldering iron that is properly grounded.

- Do not touch the hot tip of the soldering iron.

- Be aware of the potential for fire and burns.

6. What are the different types of soldering fluxes?

Types of Soldering Fluxes

- Rosin flux

- Water-soluble flux

- No-clean flux

Functions of Soldering Flux

- To remove oxides from the surface of the metal

- To improve the flow of solder

- To prevent solder from bridging

7. What is the difference between a solder mask and a solder paste?

Solder mask is a protective coating that is applied to the printed circuit board (PCB) to prevent solder from bridging between adjacent conductors. Solder paste is a mixture of solder and flux that is applied to the PCB before the components are assembled. The solder paste helps to hold the components in place and ensures that the solder joints are properly formed.

8. What are the different types of soldering equipment?

Soldering Irons

- Pen-type soldering iron

- Pencil-type soldering iron

- Butane soldering iron

Soldering Stations

- Soldering station with temperature control

- Soldering station with fume extraction

- Soldering station with automatic feeder

Other Soldering Equipment

- Solder

- Flux

- Soldering tips

- Desoldering tools

9. What are the different types of soldering techniques?

Hand Soldering

- Through-hole soldering

- Surface mount soldering

Wave Soldering

- Single-wave soldering

- Double-wave soldering

Reflow Soldering

- Vapor-phase reflow soldering

- Infrared reflow soldering

- Convection reflow soldering

10. What are the quality standards for soldered joints?

IPC-A-610

IPC-A-610 is the most widely used quality standard for soldered joints. It defines the acceptance criteria for a variety of solder joint types, including:

- Through-hole solder joints

- Surface mount solder joints

- Ball grid array (BGA) solder joints

IPC-J-STD-001

IPC-J-STD-001 is another quality standard for soldered joints. It is used by the military and aerospace industries.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Solderer-Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Solderer-Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Solderer-Assemblers are responsible for a range of tasks related to the assembly and soldering of electronic components.

1. Component Assembly

They gather and assemble electronic components, such as resistors, capacitors, and transistors, according to specifications and schematics.

- Interpreting assembly drawings and schematics

- Selecting and placing components accurately

2. Soldering

Solderer-Assemblers use soldering irons to join electrical components on printed circuit boards (PCBs). They must ensure precise application of solder and clean solder joints.

- Soldering components according to established standards

- Inspecting solder joints for quality and accuracy

3. Inspection and Testing

They inspect and test solder joints and assembled components for defects and functionality using various tools and equipment.

- Conducting visual inspections and electrical tests

- Troubleshooting and resolving assembly issues

4. Maintenance and Equipment Calibration

Solderer-Assemblers perform maintenance and calibration tasks on equipment used in the assembly process, such as soldering irons and testing equipment.

- Maintaining a clean and organized work area

- Calibrating and maintaining equipment to ensure accuracy

Interview Tips

To ace the interview for a Solderer-Assembler position, it’s important to prepare thoroughly and showcase your skills and experience.

1. Research the Company and Position

Before the interview, gather information about the company, its products, and the specific Solderer-Assembler role. This will help you understand the company’s needs and tailor your answers accordingly.

- Visit the company website for details on their products and services

- Search industry news and articles to learn about the company’s recent developments

2. Practice Your Technical Skills

Demonstrate your soldering and component assembly abilities. Practice using different types of soldering irons and work on sample PCBs to refresh your skills and build confidence.

- Create a portfolio of your previous work to showcase your soldering quality

- Practice soldering on various types of components, including SMT and through-hole

3. Prepare for Competency Questions

Be ready to answer questions that assess your technical competencies, such as:

- “Describe your process for soldering surface-mount components.”

- “How do you troubleshoot a defective solder joint?”

4. Highlight Your Soft Skills

Solderer-Assemblers often work in teams and must have good communication, attention to detail, and problem-solving abilities. Provide examples from your previous work experience that demonstrate these qualities.

- “In my previous role, I worked closely with engineers to resolve assembly issues and improve production efficiency.”

- “My attention to detail helped me identify and correct minor defects in soldered joints, preventing potential failures.”

5. Be Enthusiastic and Professional

Show your interest in the position and the company. Maintain a positive attitude and be respectful of the interviewer. Dress professionally and arrive on time for the interview.

- Prepare questions to ask the interviewer about the company and the role

- Send a thank-you note after the interview to reiterate your interest and inquire about next steps

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Solderer-Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!