Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Furnace Brazer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

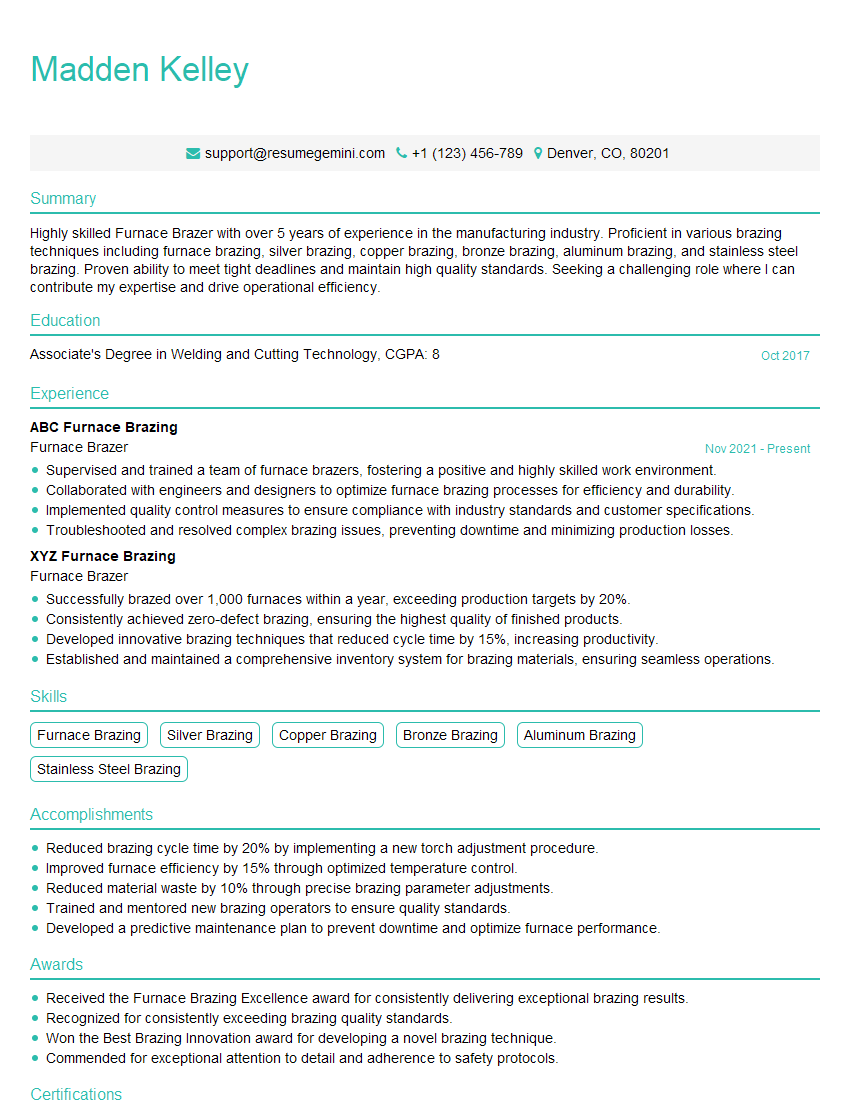

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Furnace Brazer

1. How do you maintain a safe brazing environment?

- Ensure adequate ventilation to remove fumes and gases.

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a respirator.

- Keep work areas clean and free of clutter.

- Store and handle flammable materials properly.

- Follow established safety protocols and procedures.

2. Explain the key steps involved in furnace brazing.

- Preparation: Clean and prepare the parts to be joined.

- Fluxing: Apply flux to the joint area to promote bonding.

- Assembly: Position the parts in the furnace and secure them.

- Heating: Heat the parts to the appropriate brazing temperature.

- Cooling: Allow the parts to cool slowly to avoid thermal stress.

3. Describe the types of brazing filler metals and their applications.

- Copper-base alloys: Widely used for joining a variety of metals, including copper, brass, and steel.

- Silver-base alloys: Used for high-strength, temperature-resistant joints.

- Nickel-base alloys: Used for corrosion-resistant and high-temperature applications.

4. How do you determine the appropriate heating cycle for furnace brazing?

- Consider the melting point of the filler metal.

- Evaluate the thermal properties of the parts being joined.

- Use a temperature profile to control the heating and cooling rates.

5. Discuss the significance of flux in furnace brazing.

- Removes oxides and impurities from the joint surfaces.

- Promotes wetting of the filler metal to the base metal.

- Reduces surface tension and enhances capillary flow.

6. How do you troubleshoot common problems encountered in furnace brazing?

- Insufficient joint strength: Check for improper preparation, flux application, heating cycle, or filler metal selection.

- Porosity: Inspect for moisture contamination, gas entrapment, or improper fluxing.

- Oxidation: Ensure adequate shielding gas or flux coverage.

7. Describe the role of quality control in furnace brazing.

- Establish and maintain quality standards.

- Perform inspections at various stages of the process.

- Monitor and record process parameters.

- Identify and address non-conformances.

8. How do you ensure the consistency and reliability of furnace brazed joints?

- Use standardized processes and procedures.

- Control process parameters within tight tolerances.

- Perform regular equipment calibration and maintenance.

- Train and supervise operators to ensure proper technique.

9. What safety precautions should be taken when performing furnace brazing?

- Follow established safety protocols and procedures.

- Ensure adequate ventilation to remove fumes and gases.

- Wear appropriate personal protective equipment (PPE).

- Be aware of potential hazards, such as hot surfaces and flammable materials.

10. How do you stay up-to-date on advancements in furnace brazing technology?

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Participate in online forums and discussions.

- Collaborate with other professionals in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Furnace Brazer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Furnace Brazer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Furnace Braziers are responsible for maintaining and repairing industrial furnaces, kilns, and ovens used in various industrial processes. Their key responsibilities include:

1. Furnace Maintenance

Regularly inspect and monitor furnaces to identify any potential issues or damage.

- Check and adjust furnace temperatures, pressure, and airflow.

- Lubricate and maintain furnace components, such as burners, fans, and valves.

2. Repair and Troubleshooting

Diagnose and repair any malfunctions or breakdowns in furnaces.

- Replace worn or damaged components, such as refractory linings, heating elements, and sensors.

- Troubleshoot electrical and mechanical issues to restore furnace functionality.

3. Safety and Compliance

Ensure that furnaces meet safety regulations and standards.

- Conduct regular safety inspections and audits.

- Maintain accurate records and documentation related to furnace maintenance and repairs.

4. Material Handling

Handle and transport various materials used in furnace operations.

- Load and unload materials into and out of furnaces.

- Inspect materials for defects and ensure proper storage.

Interview Tips

To prepare for a Furnace Brazer interview, it is essential to understand the key job responsibilities and highlight your relevant skills and experience.

1. Research the Company and Industry

Familiarize yourself with the company’s operations, products, and industry trends. This demonstrates your interest in the position and understanding of the industry landscape.

2. Emphasize Your Technical Skills

Highlight your proficiency in furnace maintenance, repair, and troubleshooting techniques. Provide specific examples of projects where you successfully identified and resolved furnace issues.

3. Demonstrate Safety Awareness

Emphasize your commitment to safety by discussing your knowledge of industry regulations and best practices. Mention any safety certifications or training you have obtained.

4. Prepare for Common Questions

Practice answering common interview questions related to furnace maintenance, troubleshooting, and safety. This will help you articulate your skills and experience confidently.

5. Ask Relevant Questions

Prepare thoughtful questions about the company’s furnace operations, maintenance practices, and safety protocols. This shows your enthusiasm and interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Furnace Brazer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.