Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Friction Welding Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

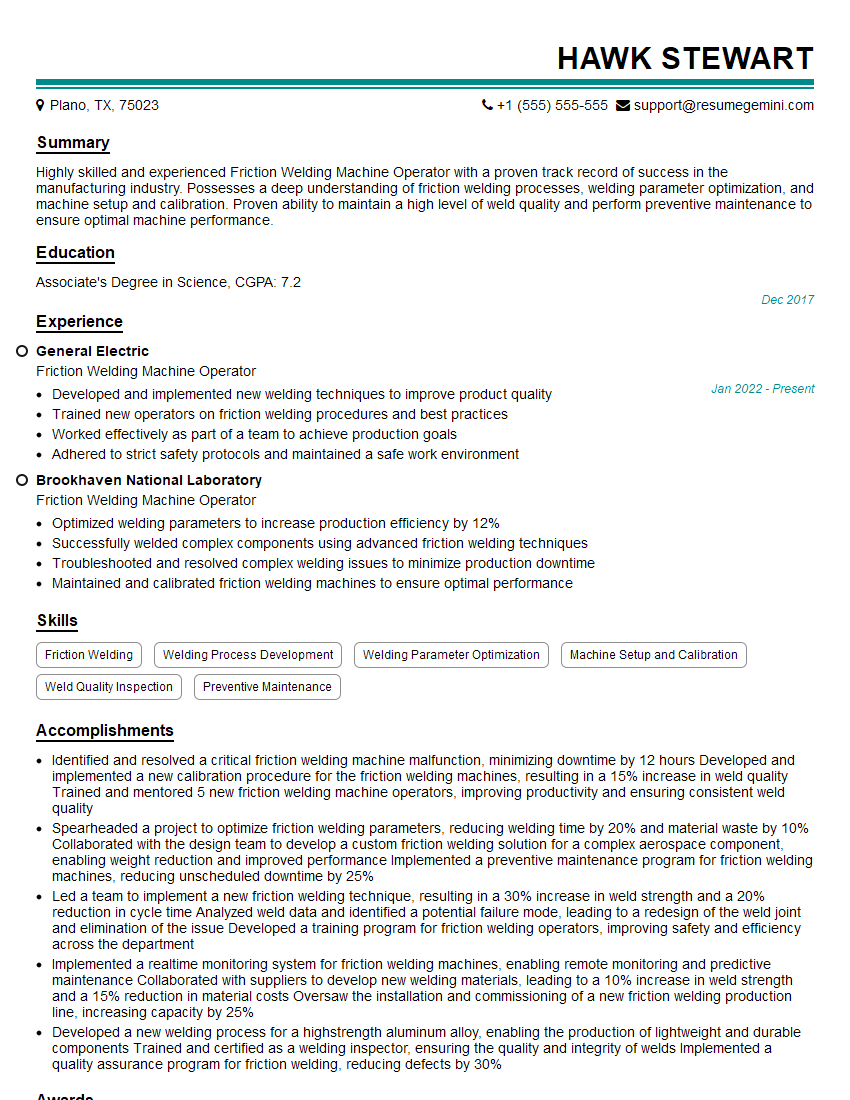

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Friction Welding Machine Operator

1. What are the key steps involved in friction welding?

- Prepare the workpieces by cleaning and chamfering the edges.

- Load the workpieces into the welding machine.

- Rotate one of the workpieces while applying pressure to the other workpiece.

- Increase the pressure until the workpieces begin to fuse together.

- Continue rotating and applying pressure until the weld is complete.

2. What are the different types of friction welding machines?

Rotary friction welding

- Uses a rotating spindle to rotate one of the workpieces.

- Suitable for welding cylindrical parts.

Linear friction welding

- Uses a linear motion to move one of the workpieces.

- Suitable for welding flat or irregular-shaped parts.

Orbital friction welding

- Uses a rotating motion to move one of the workpieces around the other workpiece.

- Suitable for welding complex shapes.

3. What are the factors that affect the quality of a friction weld?

- Surface preparation

- Clamping pressure

- Rotation speed

- Welding time

- Material properties

4. What are the advantages of friction welding?

- Strong welds

- No filler material required

- Fast welding process

- Low distortion

- Versatile process

5. What are the disadvantages of friction welding?

- Limited to joining similar metals

- Can be difficult to weld thin or delicate materials

- Requires specialized equipment

- Can be noisy and produce sparks

6. What are the safety precautions that should be taken when operating a friction welding machine?

- Wear appropriate safety gear, including eye protection, ear protection, and gloves.

- Ensure that the machine is properly grounded.

- Keep the work area clean and free of debris.

- Do not operate the machine if you are tired or under the influence of drugs or alcohol.

7. What is the difference between friction welding and other welding processes?

- Friction welding does not require filler material.

- Friction welding is a solid-state welding process, which means that the metal is not melted during the welding process.

- Friction welding is faster than other welding processes.

8. What are the applications of friction welding?

- Automotive industry

- Aerospace industry

- Medical industry

- Construction industry

9. What are the challenges of friction welding?

- Controlling the welding parameters to achieve the desired weld quality.

- Preventing defects such as porosity and cold shuts.

- Welding dissimilar metals.

10. What is the future of friction welding?

- Development of new friction welding techniques.

- Increased use of friction welding in new applications.

- Integration of friction welding with other manufacturing processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Friction Welding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Friction Welding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Friction Welding Machine Operators play a crucial role in manufacturing industries, utilizing friction welding machines to join metal components accurately and efficiently. Their key responsibilities include:

1. Machine Operation

Operate friction welding machines according to established procedures and parameters.

- Set up and calibrate the machine based on welding specifications.

- Load and align the metal components to be welded.

- Monitor machine performance and adjust settings as needed.

2. Quality Control

Ensure the quality and integrity of welded joints.

- Inspect welded parts for defects and adherence to specifications.

- Conduct non-destructive testing, such as ultrasonic or radiographic inspection, to verify weld quality.

- Maintain records and document all welding processes and results.

3. Machine Maintenance

Perform routine maintenance and repairs on friction welding machines.

- Lubricate and clean machine components regularly.

- Identify and troubleshoot machine malfunctions.

- Perform minor repairs and adjustments as authorized.

4. Safety and Compliance

Adhere to all safety regulations and industry standards.

- Wear appropriate personal protective equipment (PPE).

- Follow safety procedures for machine operation and maintenance.

- Maintain a clean and organized work environment.

Interview Tips

To ace the interview for a Friction Welding Machine Operator position, candidates should consider the following tips and hacks:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends. This demonstrates interest and enthusiasm for the role.

- Visit the company website and social media pages.

- Read industry publications and news articles.

2. Highlight Relevant Experience

Emphasize your previous experience operating friction welding machines, including any specific skills or certifications acquired.

- Provide specific examples of successful welding projects you have completed.

- Quantify your accomplishments whenever possible, using metrics such as increased production efficiency or reduced defect rates.

3. Demonstrate Safety Consciousness

Safety is paramount in manufacturing environments. Showcase your understanding of safety protocols and your commitment to following them.

- Discuss your experience with PPE and safe work practices.

- Mention any safety certifications or training you have completed.

4. Ask Informed Questions

Asking thoughtful questions at the end of the interview indicates your engagement and curiosity. It also allows you to clarify any uncertainties.

- Inquire about the specific projects you would be working on.

- Ask about the company’s commitment to training and professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Friction Welding Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!