Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Oxygraph Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

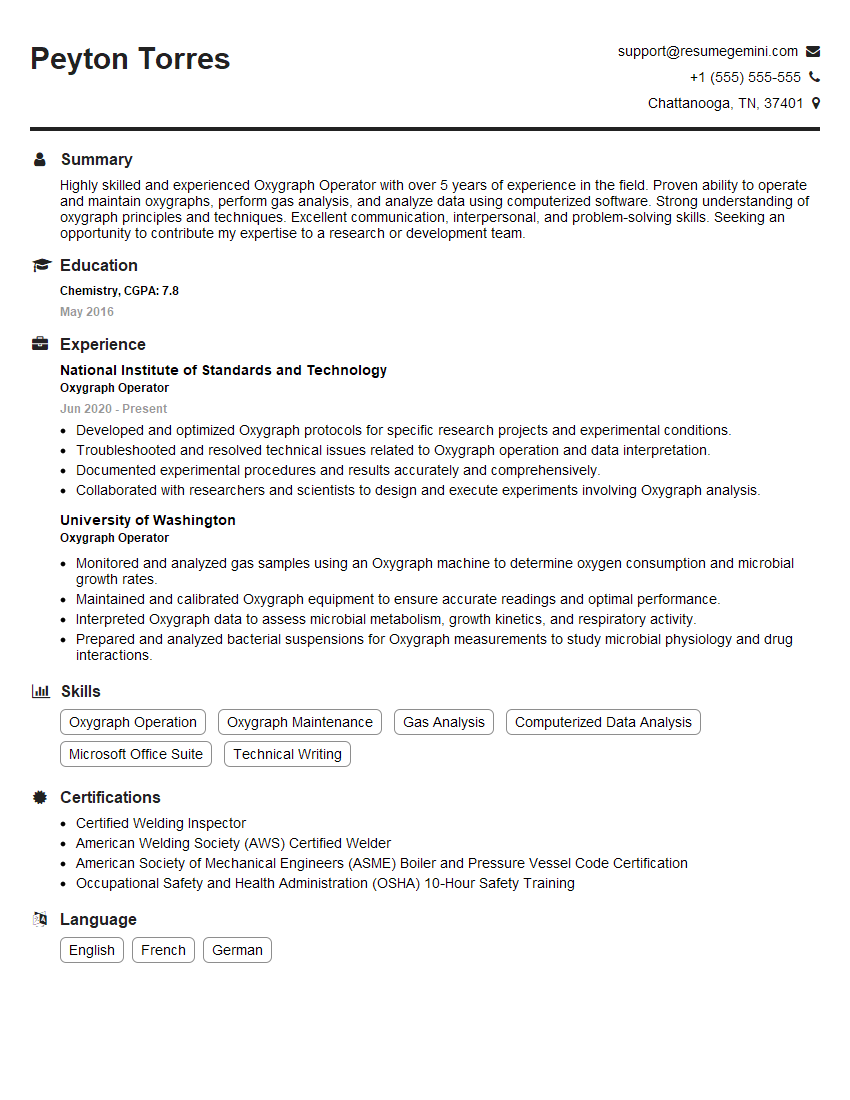

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oxygraph Operator

1. Describe the main responsibilities of an Oxygraph Operator?

An Oxygraph Operator is responsible for operating and maintaining oxygraph equipment used to measure the oxygen consumption of biological samples. Their primary responsibilities include:

- Setting up and calibrating oxygraph equipment according to established protocols.

- Preparing biological samples and loading them into the oxygraph chamber.

- Monitoring the oxygen consumption of samples and recording data using software or data loggers.

- Analyzing data to determine the respiratory activity or metabolic rate of the samples.

- Maintaining and troubleshooting oxygraph equipment to ensure optimal performance.

- Adhering to safety protocols and following established operating procedures.

2. Explain the principles of oxygraphy and how it is used to measure oxygen consumption?

Concepts of Oxygraphy

- Oxygraphy is a technique that measures the rate of oxygen consumption by biological samples.

- It is based on the principle that oxygen is consumed by cells for metabolic processes, such as respiration.

Measurement Process

- In oxygraphy, a sample is placed in a sealed chamber containing a known volume of oxygen.

- As the sample consumes oxygen, the oxygen concentration in the chamber decreases.

- An oxygen sensor detects the decrease in oxygen concentration and produces an electrical signal.

- The signal is recorded and used to calculate the rate of oxygen consumption.

3. What types of biological samples can be analyzed using oxygraphy?

Oxygraphy can be used to analyze a wide range of biological samples, including:

- Microorganisms (e.g., bacteria, yeast)

- Plant tissues (e.g., leaves, roots)

- Animal tissues (e.g., muscle, liver)

- Whole organisms (e.g., small fish, invertebrates)

- Cell suspensions (e.g., mammalian cells, stem cells)

4. What are the applications of oxygraphy in research and industry?

Oxygraphy has numerous applications in research and industry, including:

- Assessing the metabolic activity of microorganisms in environmental samples or industrial processes.

- Determining the respiratory rates of plant tissues under different environmental conditions.

- Evaluating the mitochondrial function of animal tissues in biomedical research.

- Monitoring the viability and growth of cell cultures in biotechnology and pharmaceutical industries.

- Measuring the oxygen uptake of aquatic organisms in ecological studies.

5. What are the different types of oxygraph equipment available and their respective advantages and disadvantages?

There are various types of oxygraph equipment available, each with its advantages and disadvantages:

Classical Oxygraphs

- Advantages: High accuracy and precision; suitable for long-term measurements.

- Disadvantages: Large sample size required; can be sensitive to vibrations.

Micro-Oxygraphs

- Advantages: Small sample size required; allows for real-time monitoring.

- Disadvantages: Lower accuracy compared to classical oxygraphs; may be affected by sample thickness.

Fiber-Optic Oxygraphs

- Advantages: Non-invasive; can measure oxygen consumption in specific regions of a sample.

- Disadvantages: Limited measurement range; can be sensitive to temperature fluctuations.

6. Describe the calibration and maintenance procedures you follow for oxygraph equipment?

Calibration

- Calibrate the oxygraph regularly using a known oxygen concentration (e.g., air-saturated water).

- Follow manufacturer’s instructions for calibration procedures.

Maintenance

- Clean the oxygraph chamber and sensors regularly to prevent contamination.

- Replace worn or damaged parts as needed.

- Follow manufacturer’s recommendations for maintenance intervals.

7. Explain how you analyze and interpret oxygraph data to determine oxygen consumption rates?

- Calculate the rate of oxygen consumption by measuring the slope of the oxygen consumption curve.

- Normalize the data to account for sample size or experimental conditions.

- Identify any patterns or trends in the data to determine the effects of experimental variables.

- Consider the limitations and potential sources of error in the data analysis.

8. What troubleshooting steps do you take when encountering issues with oxygraph measurements?

- Check the calibration of the equipment.

- Ensure that the sample is properly prepared and loaded.

- Inspect the oxygen sensor for damage or contamination.

- Examine the data for any anomalies or artifacts.

- Consult the manufacturer’s manual or seek technical support if necessary.

9. How do you ensure the accuracy and reliability of your oxygraph measurements?

- Follow established protocols and adhere to quality control measures.

- Calibrate the equipment regularly and maintain it in good working condition.

- Use appropriate sample preparation techniques to minimize variability.

- Replicate experiments to ensure reproducibility of results.

- Document all experimental procedures and data analysis methods.

10. What are the emerging trends and advancements in oxygraphy technology?

- Development of miniaturized and portable oxygraphs.

- Integration of sensors and microfluidics for real-time monitoring.

- Advancements in data analysis and visualization techniques.

- Applications of oxygraphy in high-throughput screening and drug discovery.

- Non-invasive oxygen consumption measurements using optical or electrochemical methods.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oxygraph Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oxygraph Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Oxygraph Operators play a crucial role in various industries, including welding, shipbuilding, and manufacturing. Their primary responsibility is to operate oxygraph cutting machines, which cut precise shapes and patterns into metal using a controlled stream of oxygen and fuel gas.

1. Operating Oxygraph Cutting Machines

Oxygraph Operators are responsible for setting up, calibrating, and operating oxygraph cutting machines. They must ensure that the machine is running smoothly and efficiently to produce high-quality cuts.

- Set up and adjust the cutting machine according to specifications.

- Monitor the cutting process and make necessary adjustments to maintain precise cuts.

- Troubleshoot and resolve any technical issues that may arise during operation.

2. Reading and Interpreting Engineering Drawings

Oxygraph Operators must be able to read and interpret engineering drawings to understand the required shapes and patterns for cutting.

- Study and analyze technical drawings to identify cutting requirements.

- Determine the appropriate cutting parameters based on the material thickness and desired shape.

3. Material Handling and Preparation

Oxygraph Operators are responsible for handling and preparing metal sheets or plates for cutting. They must ensure that the material is properly positioned and secured to achieve accurate cuts.

- Load and secure metal sheets onto the cutting bed.

- Clean and prepare the cutting surface to remove any contaminants.

- Inspect the material for defects or inconsistencies that may affect the cutting process.

4. Post-Cutting Inspection and Quality Control

After the cutting process is complete, Oxygraph Operators are responsible for inspecting the cut parts to ensure they meet the required specifications.

- Visually inspect the cut pieces for accuracy, cleanliness, and surface finish.

- Measure and verify dimensions to confirm compliance with the engineering drawings.

- Identify and rectify any defects or deviations from the specifications.

Interview Tips

To ace an Oxygraph Operator interview, candidates should thoroughly prepare by researching the role, practicing their technical skills, and developing strong communication and interpersonal abilities. Here are some tips to help candidates succeed:

1. Research the Company and Position

Before the interview, candidates should thoroughly research the company’s background, industry standing, and the specific requirements of the Oxygraph Operator position. This knowledge will demonstrate their interest in the opportunity and enable them to tailor their answers to the company’s needs.

- Visit the company’s website and social media pages.

- Read industry publications and articles to stay updated on current trends.

2. Practice Technical Skills

Oxygraph Operators must possess strong technical skills. Candidates should practice reading and interpreting engineering drawings, setting up and calibrating cutting machines, and troubleshooting common issues. They can do this by:

- Reviewing technical manuals and online resources.

- Simulating the cutting process using software or hands-on practice.

- Seeking guidance from experienced Oxygraph Operators.

3. Develop Communication and Interpersonal Abilities

Oxygraph Operators often work in teams and interact with supervisors, engineers, and clients. They should possess strong communication and interpersonal skills to convey information clearly, collaborate effectively, and maintain positive relationships.

- Practice active listening and asking clarifying questions.

- Prepare examples of how they have successfully resolved conflicts or worked in a team environment.

4. Prepare for Common Interview Questions

Candidates should anticipate common interview questions and prepare thoughtful responses that highlight their qualifications. Some typical questions include:

- Tell me about your experience operating oxygraph cutting machines.

- How do you read and interpret engineering drawings?

- Describe a challenging situation you faced as an Oxygraph Operator and how you overcame it.

- What are your strengths and weaknesses as an Oxygraph Operator?

5. Be Enthusiastic and Professional

Candidates should convey enthusiasm for the role and the industry. They should dress professionally, arrive on time for the interview, and maintain a positive and respectful demeanor throughout the process. By demonstrating a genuine interest in the opportunity and a commitment to the craft, they can increase their chances of making a strong impression on the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Oxygraph Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!