Are you gearing up for an interview for a Resistance Machine Welder Setter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Resistance Machine Welder Setter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

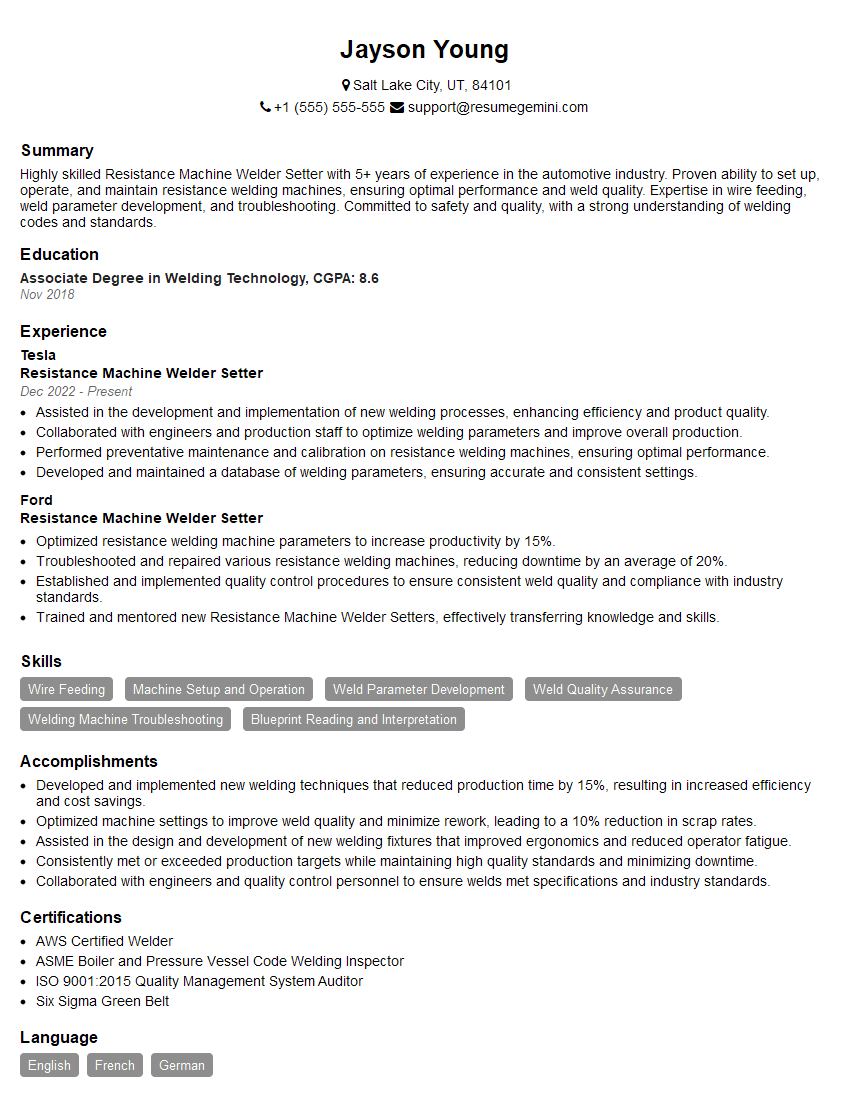

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Resistance Machine Welder Setter

1. Resistance Machine Welder Setter interview question?

Describe the critical parameters that influence the quality of the welds produced by resistance welding machines and explain their effects.

- Weld current: Affects the heat generated and weld strength.

- Weld time: Determines the duration of heating and fusion.

- Electrode force: Applies pressure to the joint and ensures good electrical contact.

- Electrode material and shape: Influence the thermal conductivity and current density.

- Weld surface preparation: Proper cleaning and surface finish ensure good electrical conductivity.

2. Resistance Machine Welder Setter interview question?

Maintenance and Troubleshooting

- Inspect electrodes regularly for wear and replace when necessary.

- Clean and lubricate moving parts to prevent seizing.

- Check electrical connections for loose wires or terminals.

- Troubleshoot weld quality issues by analyzing weld appearance, strength, and joint integrity.

- Calibrate equipment periodically to ensure accurate and reliable operation.

Safety

- Wear appropriate welding gear, including helmet, gloves, and safety glasses.

- Ensure that the work area is well-ventilated to remove welding fumes.

- Properly ground and isolate the welding machine for electrical safety.

3. Resistance Machine Welder Setter interview question?

Explain the different types of resistance welding processes and their applications.

- Spot welding: Joining two metal sheets at a localized point.

- Seam welding: Continuous welding of overlapping metal sheets.

- Projection welding: Welding studs or projections on one sheet to another.

- Flash welding: Welding by heating metal surfaces with an electric arc and forging them together.

- Percussion welding: Joining thin or dissimilar metals using a high-speed impact.

4. Resistance Machine Welder Setter interview question?

Describe the various methods for measuring and ensuring the quality of resistance welds.

- Visual inspection: Checking weld appearance, size, and integrity.

- Destructive testing: Performing mechanical tests to assess weld strength.

- Non-destructive testing (NDT): Using techniques such as radiography or ultrasonic testing to evaluate weld quality without damaging it.

5. Resistance Machine Welder Setter interview question?

Explain the key factors to consider when selecting the appropriate resistance welding equipment for a specific application.

- Material thickness and type

- Desired weld strength and quality

- Production volume and cycle time

- Space and accessibility constraints

- Budget

6. Resistance Machine Welder Setter interview question?

Describe the role of welding electrodes in resistance welding and explain their selection and maintenance.

- Conduct electricity and transmit heat to the weld area.

- Shape and size influence current density and weld quality.

- Materials such as copper, copper alloys, or tungsten used for electrodes.

- Regular cleaning and dressing of electrodes to maintain contact and prevent overheating.

7. Resistance Machine Welder Setter interview question?

Explain the concept of heat balance in resistance welding and how it affects weld quality.

- Balance between heat input and heat dissipation.

- Excess heat can lead to burn-through or weld defects.

- Insufficient heat can result in weak or incomplete welds.

- Factors influencing heat balance: material properties, weld parameters, and electrode design.

8. Resistance Machine Welder Setter interview question?

Describe the importance of proper cooling in resistance welding and explain different cooling methods.

- Controls cooling rate and weld grain structure.

- Prevents weld cracking and brittleness.

- Cooling methods: air cooling, water cooling, or forced air cooling.

9. Resistance Machine Welder Setter interview question?

Explain the advantages and disadvantages of resistance welding compared to other joining methods.

Advantages:

- Fast and efficient

- Repeatable and consistent

- Low distortion

Disadvantages:

- Limited joint design possibilities

- Weld strength can be affected by material thickness

- Can require specialized equipment and skilled operators

10. Resistance Machine Welder Setter interview question?

Describe the future trends and advancements in resistance welding technology.

- Digital control and monitoring systems

- Automated weld parameter optimization

- Advanced materials and electrode designs

- Integration with robotics and automated production lines

- Development of new welding processes

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Resistance Machine Welder Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Resistance Machine Welder Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Resistance Machine Welder Setters are responsible for setting up and operating resistance welding machines to produce welded assemblies. They work with engineers and other production staff to develop and implement welding procedures, and they ensure that the equipment is operating properly to produce high-quality welds.

1. Set Up and Operate Resistance Welding Machines

Resistance Machine Welder Setters are responsible for setting up and operating a variety of resistance welding machines, including spot welders, projection welders, and seam welders. They must be able to read and interpret blueprints and welding specifications, and they must be able to adjust the machine settings to achieve the desired weld quality.

2. Develop and Implement Welding Procedures

Resistance Machine Welder Setters work with engineers and other production staff to develop and implement welding procedures. These procedures specify the welding parameters, such as the welding current, voltage, and time, as well as the fixturing and tooling to be used. Resistance Machine Welder Setters must be able to troubleshoot welding problems and make adjustments to the welding process as needed.

3. Ensure Equipment is Operating Properly

Resistance Machine Welder Setters are responsible for ensuring that the welding equipment is operating properly. They must be able to identify and troubleshoot mechanical and electrical problems, and they must be able to perform routine maintenance on the equipment.

4. Maintain Quality Standards

Resistance Machine Welder Setters are responsible for maintaining quality standards for the welded assemblies. They must be able to inspect welds and identify any defects. They must also be able to take corrective action to prevent defects from occurring in the future.

Interview Tips

Preparing for an interview for a Resistance Machine Welder Setter position can be daunting, but with the right preparation, you can increase your chances of success.

1. Be Prepared to Discuss Your Experience

In your interview, you will likely be asked about your experience with resistance welding. Be sure to highlight your skills and knowledge in this area, and be prepared to discuss specific projects that you have worked on.

2. Know the Different Types of Resistance Welding Machines

There are a variety of different types of resistance welding machines, and each type has its own advantages and disadvantages. Be sure to familiarize yourself with the different types of machines and their applications so that you can answer questions about them in your interview.

3. Understand Welding Parameters

Welding parameters are the settings on a resistance welding machine that determine the quality of the weld. Be sure to understand the different welding parameters and how they affect the weld quality.

4. Be Able to Troubleshoot Welding Problems

Resistance welding machines can sometimes experience problems. Be sure to be prepared to discuss how you would troubleshoot and fix common welding problems.

5. Be Familiar with Safety Regulations

Resistance welding can be a hazardous process, so it is important to be familiar with the safety regulations that apply to this process. Be sure to review the safety regulations before your interview so that you can answer questions about them.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Resistance Machine Welder Setter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.