Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Soldering Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

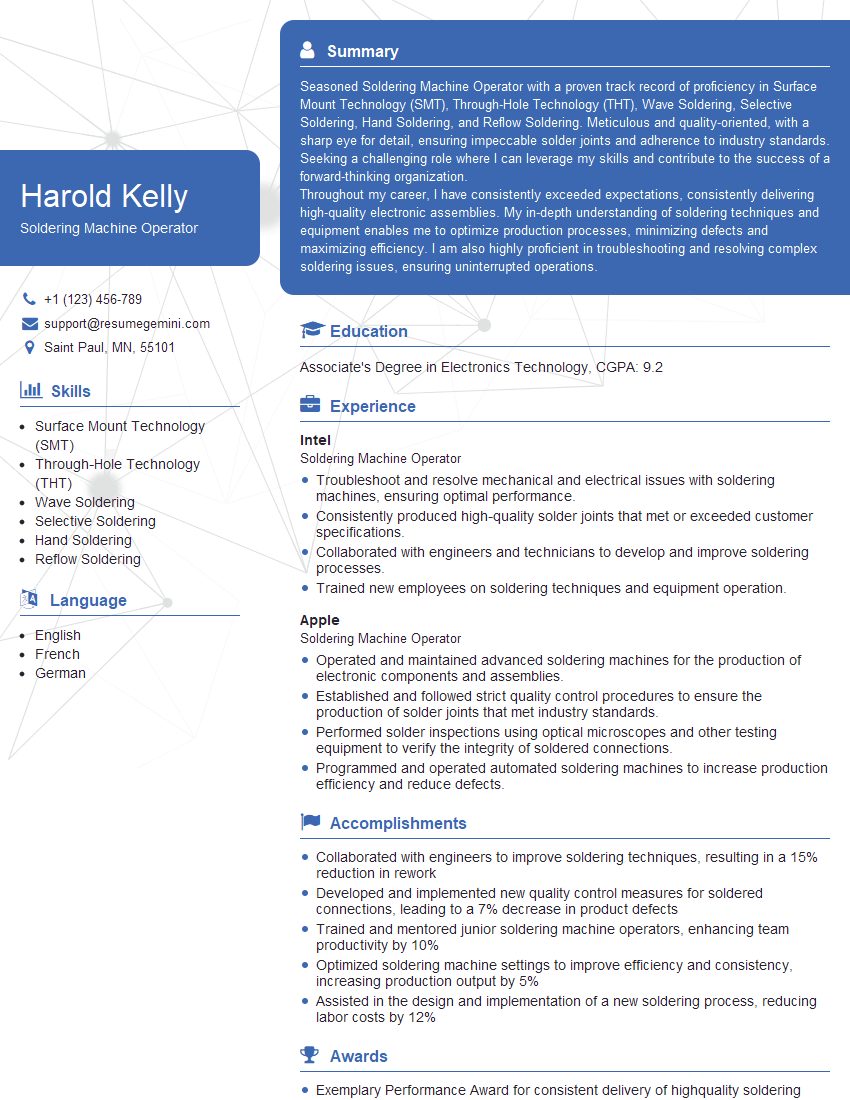

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Soldering Machine Operator

1. What are the different types of soldering machines?

There are various types of soldering machines, each suited for specific applications. Here are the main types:

- Wave Soldering Machine: Used for high-volume production, it solders components by passing them over a wave of molten solder.

- Reflow Soldering Machine: Employs a controlled temperature profile to melt solder paste and reflow solder joints.

- Selective Soldering Machine: Automates the soldering process for complex assemblies, allowing for precise placement and control.

- Hand Soldering Station: A basic tool used for manual soldering, providing temperature control and a soldering iron.

- Laser Soldering Machine: Utilizes a focused laser beam to melt solder, offering high precision and speed.

2. Explain the process of wave soldering.

Wave Solder Machine Operation:

- Flux Application: Circuit boards pass through a fluxer to remove oxides and promote solder adhesion.

- Preheat: Boards are preheated to reduce thermal shock and improve solderability.

- Soldering: Boards pass over a molten solder wave, creating solder joints.

- Cooling: Boards are cooled to solidify the solder and prevent bridging.

Wave Soldering Parameters:

- Solder Temperature: Typically ranges from 240-260°C.

- Wave Height: Controlled to ensure proper solder coverage without bridging.

- Wave Velocity: Adjusted to provide adequate time for solder joint formation.

3. What are the key factors to consider when selecting a soldering machine?

When selecting a soldering machine, several factors need to be considered:

- Type of Application: Determine the specific soldering requirements, such as batch production, high-volume manufacturing, or precision assembly.

- Throughput: Consider the required production rate and cycle time.

- Flexibility: Assess whether the machine can handle different board sizes and component types.

- Solder Joint Quality: Evaluate the machine’s ability to produce reliable and consistent solder joints.

- Budget: Determine the available financial resources for the equipment.

4. How do you troubleshoot common soldering defects?

To troubleshoot common soldering defects, follow these steps:

- Identify the Defect: Examine the solder joint and determine the type of defect (e.g., bridging, cold joint, tombstoning).

- Check Soldering Parameters: Verify that the soldering temperature, time, and flux application are within optimal ranges.

- Inspect Components: Ensure that components are properly aligned and free of contamination.

- Clean the Equipment: Regularly clean the soldering iron tips and wave solder machine to remove oxides and debris.

- Consult Reference Materials: Utilize technical manuals or online resources for guidance on specific defect troubleshooting.

5. What safety precautions should be observed when operating a soldering machine?

To ensure a safe working environment, follow these safety precautions:

- Use Proper Protective Gear: Wear protective gloves, eye goggles, and a face shield to prevent injuries from solder splatter.

- Ventilation: Ensure adequate ventilation to remove solder fumes.

- Handling Hot Equipment: Use insulated tools and protective gloves to handle hot soldering irons and machines.

- Electrical Safety: Ground the equipment properly to prevent electrical shocks.

- Fire Safety: Keep a fire extinguisher nearby and avoid using flammable materials in the work area.

6. What is the difference between soft solder and hard solder?

Soft solder and hard solder are two distinct types of solder alloys used for different applications:

- Soft Solder: Contains a lower melting point (typically below 300°C) and is commonly used in electronics, plumbing, and sheet metal work.

- Hard Solder: Has a higher melting point (above 300°C) and is used in applications requiring higher strength and durability, such as in jewelry making and metalworking.

7. How do you maintain and calibrate a soldering machine?

To maintain and calibrate a soldering machine, follow these steps:

- Regular Cleaning: Clean the soldering iron tips, nozzles, and other components to remove flux residue and oxides.

- Temperature Calibration: Use a temperature probe or multimeter to verify the accuracy of the machine’s temperature settings.

- Wave Height Adjustment: Ensure the wave height in a wave soldering machine is set correctly to prevent solder bridging.

- Flux Application Check: Inspect the flux application system to ensure it is delivering the proper amount of flux.

- Preventive Maintenance: Schedule regular maintenance intervals to inspect and replace worn parts, such as belts, nozzles, and tips.

8. What are the quality control measures for soldering operations?

To ensure the quality of soldered joints, implement the following quality control measures:

- Visual Inspection: Examine solder joints for proper wetting, lack of voids, and absence of bridging or cold joints.

- Electrical Testing: Perform electrical continuity tests to verify the electrical integrity of the joints.

- Mechanical Stress Testing: Subject solder joints to mechanical stress tests to assess their strength and durability.

- Environmental Testing: Conduct environmental tests (e.g., temperature cycling, humidity testing) to evaluate the long-term reliability of the solder joints.

- Process Monitoring: Monitor the soldering process parameters, such as temperature, solder paste application, and cycle time, to ensure consistency.

9. What is the role of flux in soldering?

Flux plays a crucial role in soldering by:

- Removing Oxides: Flux reacts with and removes oxides from metal surfaces, allowing the solder to make a strong bond.

- Promoting Wetting: Flux enhances the wetting properties of solder, ensuring that it spreads evenly over the metal surfaces.

- Preventing Solder Bridging: Flux helps prevent solder from bridging between adjacent conductors by creating a protective barrier.

- Improving Electrical Conductivity: The flux residue left after soldering can enhance the electrical conductivity of the joint.

10. What are the common types of solder defects and their causes?

Common solder defects and their causes include:

- Bridging: When solder connects adjacent conductors unintentionally, creating a short circuit.

- Cold Joint: A solder joint that lacks proper bonding, resulting in a weak or intermittent connection.

- Tombstoning: A component that stands upright on the board due to excessive solder on one side.

- Solder Balling: When solder forms into small balls instead of wetting the metal surfaces.

- Flux Spattering: When flux is ejected from the joint during soldering, creating a mess and potential short circuits.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Soldering Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Soldering Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Soldering Machine Operator is a production professional responsible for operating and maintaining soldering machines utilized in the manufacturing process.

1. Machine Operation

– Set up, calibrate, and operate soldering machines according to established specifications. – Load and unload PCBs, components, and other materials into the machine. – Monitor the soldering process and adjust parameters to ensure proper connections. – Perform regular maintenance and troubleshooting on soldering machines.

2. Quality Control

– Inspect soldered joints to ensure they meet quality standards. – Use measuring tools and magnification equipment to verify joint integrity. – Maintain accurate records of inspections and identify any potential defects.

3. Production and Efficiency

– Meet production targets while maintaining high levels of quality. – Identify bottlenecks and implement continuous improvement measures. – Work with other operators and departments to streamline production processes.

4. Safety and Compliance

– Follow established safety procedures and use personal protective equipment. – Comply with environmental regulations and ensure proper disposal of hazardous materials. – Participate in training and certification programs to enhance skills and knowledge.

Interview Tips

Preparing for an interview for a Soldering Machine Operator position requires research, practice, and confidence. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

– Visit the company website and social media pages to learn about their business, culture, and products. – Review the job description carefully to identify the key responsibilities and qualifications. – Prepare to discuss how your skills and experience align with the requirements of the role.

2. Practice Your Answers

– Anticipate common interview questions related to your experience, skills, and motivation. – Prepare concise and well-structured answers that highlight your strengths and qualifications. – Use the STAR method (Situation, Task, Action, Result) to provide specific examples of your accomplishments.

3. Showcase Your Technical Expertise

– Discuss your understanding of soldering techniques, machine operation, and quality control procedures. – Provide examples of how you have used your technical skills to solve problems and improve efficiency. – Be prepared to answer questions about specific types of soldering machines and materials.

4. Emphasize Your Problem-Solving Abilities

– Highlight your ability to identify and resolve issues related to soldering equipment and processes. – Provide examples of how you have used your analytical and troubleshooting skills to reduce downtime and maintain production quality.

5. Demonstrate Your Safety and Compliance Knowledge

– Explain your understanding of safety protocols and environmental regulations related to soldering operations. – Discuss your experience with using personal protective equipment and handling hazardous materials.

6. Show Your Enthusiasm and Motivation

– Express your interest in the position and the company. – Explain why you are excited about the opportunity to contribute to the team. – Be confident and enthusiastic about your abilities and willingness to learn and grow.

Next Step:

Now that you’re armed with the knowledge of Soldering Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Soldering Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini