Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rod Welder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

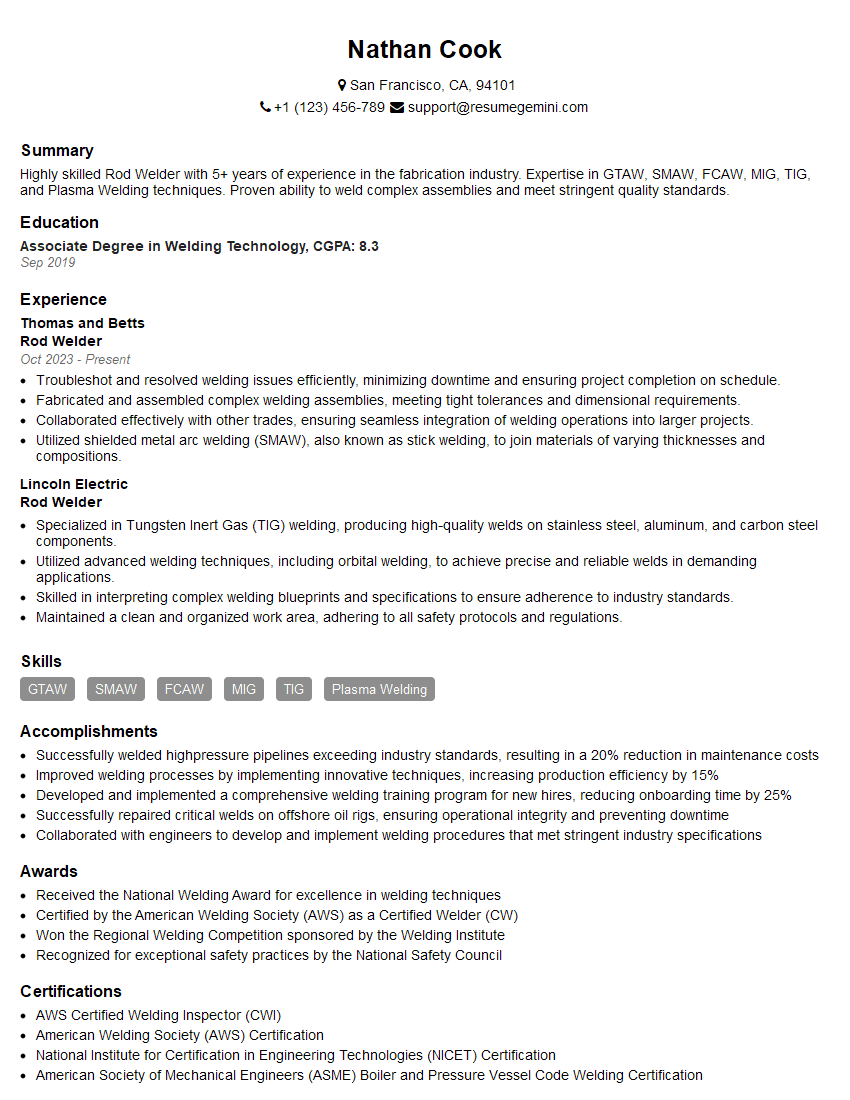

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rod Welder

1. Tell me about the different welding techniques you are proficient in and provide examples of when you have used them?

– Gas Metal Arc Welding (GMAW): Used in a variety of applications, including automotive manufacturing and shipbuilding. – Gas Tungsten Arc Welding (GTAW): Used for welding thin materials and creating precise welds. – Flux-Cored Arc Welding (FCAW): Used in industrial settings and construction projects. – Shielded Metal Arc Welding (SMAW): Used for heavy-duty welding applications, such as in construction and shipbuilding.

2. What is the ASME Boiler and Pressure Vessel Code, and how have you applied it in your work?

Compliance with Safety Standards

- Ensures adherence to industry standards for welding pressure vessels and boilers.

- Provides guidelines for material selection, weld procedures, and testing to meet safety requirements.

Quality Control and Documentation

- Requires detailed documentation of welding procedures, materials used, and inspection results.

- Facilitates quality assurance and traceability throughout the welding process.

Specific Projects

- Welded pressure vessels according to ASME Code Section VIII, Division 1, ensuring compliance with design specifications.

- Developed weld procedures and conducted welder qualifications as per ASME Code requirements.

3. Describe the steps involved in welding a pipeline, and highlight any specific challenges you have encountered.

– Site Preparation: Clearing the work area, setting up equipment, and ensuring safety measures. – Pipe Alignment: Aligning the pipes accurately using tools like laser levelers and measuring tapes. – Joint Preparation: Cleaning and beveling the pipe ends to create a proper weld joint. – Welding: Using appropriate welding techniques, such as GMAW or FCAW, to join the pipes. – Inspection: Conducting visual, radiographic, or ultrasonic inspections to ensure weld quality. – Challenges: – Maintaining weld consistency and quality over long distances. – Dealing with weather conditions, such as extreme heat or cold, which can affect the welding process. – Working in confined spaces or difficult-to-access areas.

4. How do you ensure the quality of your welds, and what are some common defects you have encountered?

– Visual Inspection: Regularly examining welds for any visible defects, such as cracks, porosity, or undercut. – Non-Destructive Testing (NDT): Utilizing methods like radiography, ultrasonic testing, or magnetic particle testing to detect internal flaws. – Destructive Testing: Conducting tensile tests, bend tests, or hardness tests on sample welds to assess their mechanical properties. – Common Defects: – Cracks: Resulting from stresses, improper welding techniques, or material flaws. – Porosity: Gas bubbles trapped in the weld, leading to reduced strength and corrosion resistance. – Undercut: Groove formed at the edge of the weld, causing a loss of material and potential stress concentrations.

5. What are the safety protocols you follow when working with welding equipment, and how do you maintain a safe work environment?

– Proper Attire: Wearing protective clothing, including gloves, welding helmet, and appropriate footwear. – Hazard Identification: Recognizing potential hazards, such as electrical, fire, and fume exposure. – Ventilation: Ensuring adequate ventilation to prevent fume accumulation and maintain air quality. – Equipment Maintenance: Regularly inspecting and maintaining welding equipment, including cables, hoses, and power sources. – Work Area Safety: Keeping the work area free of tripping hazards, flammable materials, and welding debris.

6. How do you stay up-to-date with the latest welding technologies and industry best practices?

– Attend industry conferences and workshops to learn about new techniques and advancements. – Read technical journals and industry publications to stay informed about best practices and research findings. – Participate in online forums and discussion groups to connect with other professionals and share knowledge. – Obtain certifications from welding organizations, such as the American Welding Society (AWS), to demonstrate proficiency.

7. What is the difference between preheat and post-weld heat treatment, and when are each typically used?

– Preheat: – Involves heating the base metal before welding to reduce the risk of cracking. – Typically used for welding thick materials, high-strength steels, and dissimilar metals. – Post-Weld Heat Treatment (PWHT): – Involves heating the welded joint after welding to improve its properties. – Typically used to relieve residual stresses, improve ductility, and enhance strength in critical applications.

8. Tell me about a time when you had to troubleshoot and resolve a complex welding issue.

– Describe the problem encountered, including the symptoms and potential causes. – Explain the steps taken to diagnose the issue, such as visual inspection, testing, and research. – Discuss the solution implemented, including any modifications to welding parameters, equipment, or materials. – Highlight the results achieved and how they resolved the welding issue.

9. How do you manage multiple welding projects simultaneously while ensuring quality and meeting deadlines?

– Planning and Prioritization: Setting priorities, creating schedules, and allocating resources effectively. – Communication and Coordination: Communicating regularly with team members, suppliers, and clients to ensure smooth project execution. – Quality Control: Implementing quality control measures, such as regular inspections and testing, to maintain high standards. – Collaboration and Teamwork: Working effectively with colleagues and supervisors to share knowledge, assist with tasks, and overcome challenges.

10. What are your career goals and aspirations as a Rod Welder?

– Express interest in advancing skills and knowledge in welding technologies. – Discuss aspirations for leadership roles or specialized certifications. – Explain how the position aligns with career goals and provides opportunities for growth and development. – Emphasize commitment to the welding profession and continuous improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rod Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rod Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rod Welders are responsible for joining metal components using welding techniques. They work in various industries, including construction, manufacturing, and repair.

1. Welding

Rod Welders are proficient in a variety of welding techniques, including arc welding, gas welding, and flux-cored arc welding.

- Prepare metal surfaces for welding, including cleaning, grinding, and preheating.

- Select the appropriate welding equipment and materials for the job.

- Operate welding equipment to join metal components.

- Inspect welds to ensure they meet quality standards.

2. Fabrication

Rod Welders may also be involved in fabrication tasks, such as cutting, bending, and shaping metal components.

- Read and interpret blueprints and drawings.

- Cut and shape metal components using hand tools or power equipment.

- Assemble and fit metal components.

3. Maintenance

Rod Welders may also perform maintenance tasks, such as repairing or replacing worn or damaged components.

- Identify and repair welding defects.

- Troubleshoot and repair welding equipment.

- Maintain a clean and safe work environment.

4. Safety

Rod Welders must follow all safety regulations and procedures.

- Wear appropriate personal protective equipment (PPE), including welding helmets, gloves, and aprons.

- Follow proper ventilation and fire safety procedures.

- Work in a clean and well-maintained environment.

Interview Tips

To ace the interview for a Rod Welder position, candidates should be prepared to discuss their welding skills and experience.

1. Research the Company

Before the interview, candidates should research the company they are applying to. This will help them understand the company’s culture, values, and business objectives.

- Visit the company website.

- Read news articles and press releases about the company.

- Talk to people who work for the company.

2. Practice Your Answers

Candidates should practice answering common interview questions, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”.

- Write out your answers in advance.

- Practice saying your answers out loud.

- Get feedback from a friend or family member.

3. Be Prepared to Discuss Your Welding Skills

Candidates should be prepared to discuss their welding skills and experience in detail.

- Provide examples of your welding projects.

- Explain your knowledge of different welding techniques.

- Describe your safety procedures.

4. Ask Questions

At the end of the interview, candidates should ask questions to show their interest in the position and the company.

- Ask about the company’s culture.

- Ask about the company’s growth plans.

- Ask about the training and development opportunities available.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rod Welder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!