Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Thermit Welding Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

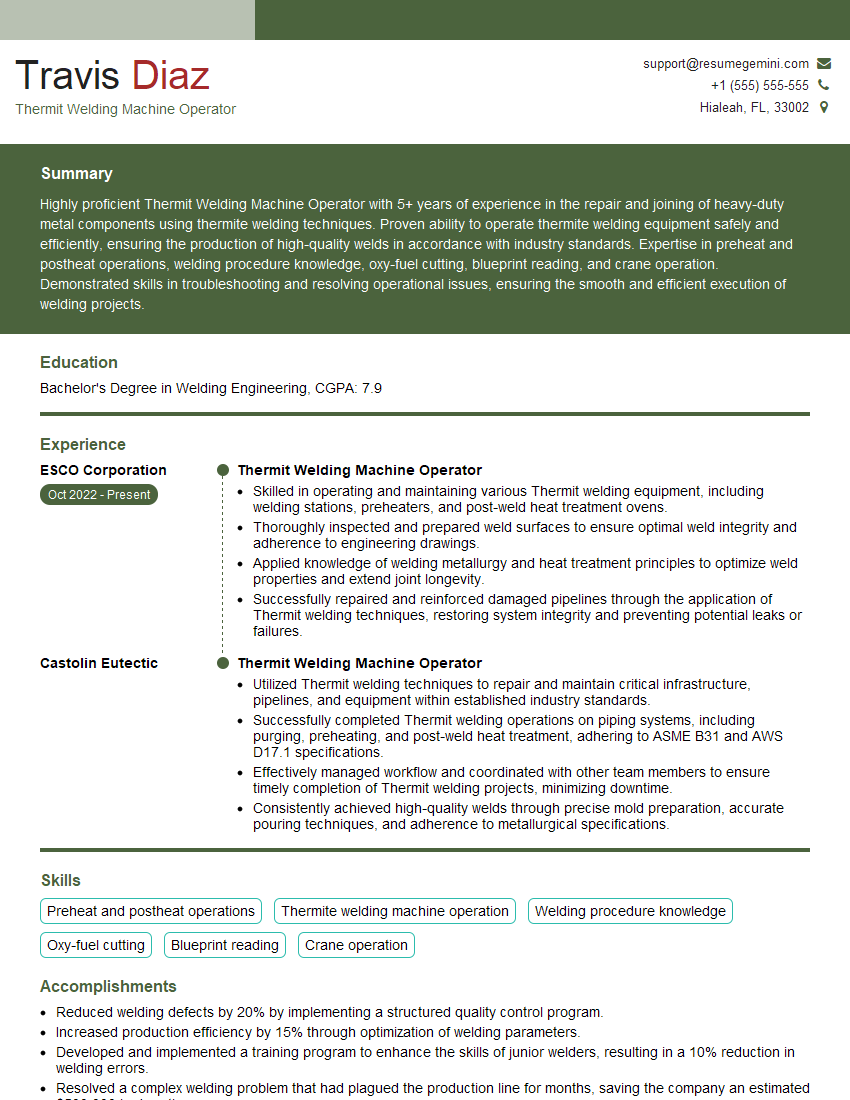

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Thermit Welding Machine Operator

1. What are the key responsibilities of a Thermit Welding Machine Operator?

- Preparing and setting up the thermit welding machine for operation

- Operating the machine to weld railway tracks, pipelines, and other metal structures

- Maintaining the machine and its components to ensure optimal performance

2. What are the different types of thermit welding processes?

Manual Thermit Welding Process:

- Involves the use of manual tools and equipment to prepare and weld the joint

- Requires more skill and experience from the operator

Semi-Automatic Thermit Welding Process:

- Utilizes semi-automatic equipment to prepare and weld the joint

- Faster and more efficient than manual welding

Automatic Thermit Welding Process:

- Employs robotic or automated equipment to perform the welding process

- Offers the highest level of consistency and quality

3. What are the safety precautions an operator should observe while working with thermit welding equipment?

- Wearing appropriate protective clothing (gloves, mask, apron)

- Ensuring proper ventilation to avoid exposure to fumes

- Storing and handling thermite materials safely

- Following established safety protocols and procedures

4. What are the common defects that can occur during thermit welding?

- Inclusions or voids

- Weld cracks

- Undercuts or lack of fusion

- Porosity

5. How do you troubleshoot and resolve common thermit welding defects?

- Checking the welding parameters and making necessary adjustments

- Examining the joint preparation and ensuring proper cleaning and alignment

- Inspecting the thermite materials and equipment for any issues

- Adopting appropriate corrective measures based on the identified root cause

6. What are the advantages and disadvantages of using thermit welding?

Advantages:

- Strong and reliable welds

- Suitable for welding large and thick sections

- Can be used in remote or field locations

Disadvantages:

- Time-consuming process

- Requires specialized skills and training

- Can generate hazardous fumes

7. What is the importance of preheating the weld joint before thermit welding?

- Preheating reduces the risk of thermal stresses

- Ensures a uniform temperature distribution in the weld area

- Improves the metallurgical properties of the weld

- Promotes better fusion and reduces the likelihood of defects

8. What is the purpose of using a flux in thermit welding?

- Flux creates a protective layer over the molten metal

- Prevents oxidation and impurities from contaminating the weld

- Improves the fluidity and penetration of the molten metal

9. How do you ensure proper alignment and fit-up of the weld joint before welding?

- Use measuring tools and gauges to verify dimensions

- Check for any gaps or misalignments

- Tack weld the joint to hold it in place

- Ensure the joint is properly cleaned and free of any debris

10. What are the post-welding procedures that need to be followed for thermit welded joints?

- Allow the weld to cool slowly and uniformly

- Remove the welding mold and slag

- Inspect the weld for any defects

- Perform necessary post-weld treatments (e.g., heat treatment, stress relief)

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Thermit Welding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Thermit Welding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Thermit Welding Machine Operator plays a critical role in welding and joining metal components using the thermit process. Their primary responsibilities include:

1. Thermit Welding Operations

Conduct thermit welding operations to join, repair, or build up metal components, following specified procedures and safety guidelines.

- Prepare and assemble welding molds and materials.

- Control and monitor the thermit welding process to ensure proper fusion and weld quality.

- Grind and finish welded joints to meet specifications.

2. Equipment Maintenance and Calibration

Maintain and calibrate thermit welding equipment, including the crucible, ignition system, and welding molds.

- Inspect and clean equipment regularly to ensure optimal performance.

- Troubleshoot and repair equipment as needed.

- Calibrate equipment to ensure accuracy and precision.

3. Safety and Compliance

Adhere to safety regulations and guidelines related to thermit welding operations.

- Wear appropriate personal protective equipment (PPE).

- Control and dispose of hazardous materials safely.

- Follow proper operating procedures to minimize risks.

4. Documentation and Reporting

Document and report on thermit welding activities and results.

- Maintain accurate records of welding parameters and inspections.

- Report any incidents or deviations from standard procedures.

- Collaborate with inspectors to ensure compliance.

Interview Preparation Tips for a Thermit Welding Machine Operator

To ace an interview for a Thermit Welding Machine Operator position, consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s background, industry, and specific requirements for the role. This shows your interest and preparation.

- Review the company website, LinkedIn page, and industry news.

- Understand the specific thermit welding techniques and applications relevant to the job.

2. Highlight Your Skills and Experience

Emphasize your technical abilities in thermit welding, including your experience with different welding materials and processes.

- Quantify your accomplishments and provide specific examples of your successful thermit welding projects.

- Describe your proficiency in operating and maintaining thermit welding equipment.

3. Demonstrate Your Safety Consciousness

Thermit welding involves working with hazardous materials and high temperatures. Showcase your understanding of safety protocols and your commitment to maintaining a safe work environment.

- Explain your knowledge of OSHA regulations and industry best practices for thermit welding.

- Describe your experience in handling and storing hazardous materials safely.

4. Showcase Your Problem-Solving Abilities

Thermit welding often requires quick decision-making and troubleshooting. Highlight your ability to identify and resolve problems effectively.

- Provide examples of how you have overcome challenges or resolved unexpected issues during thermit welding operations.

- Explain your approach to problem-solving and your ability to think critically.

5. Be Prepared for Technical Questions

Anticipate technical questions related to thermit welding, such as:

- Describe the exothermic reaction involved in thermit welding.

- What safety precautions should be taken when handling thermit materials and equipment?

- How do you calculate the amount of thermit required for a specific weld?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Thermit Welding Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.