Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Welding Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

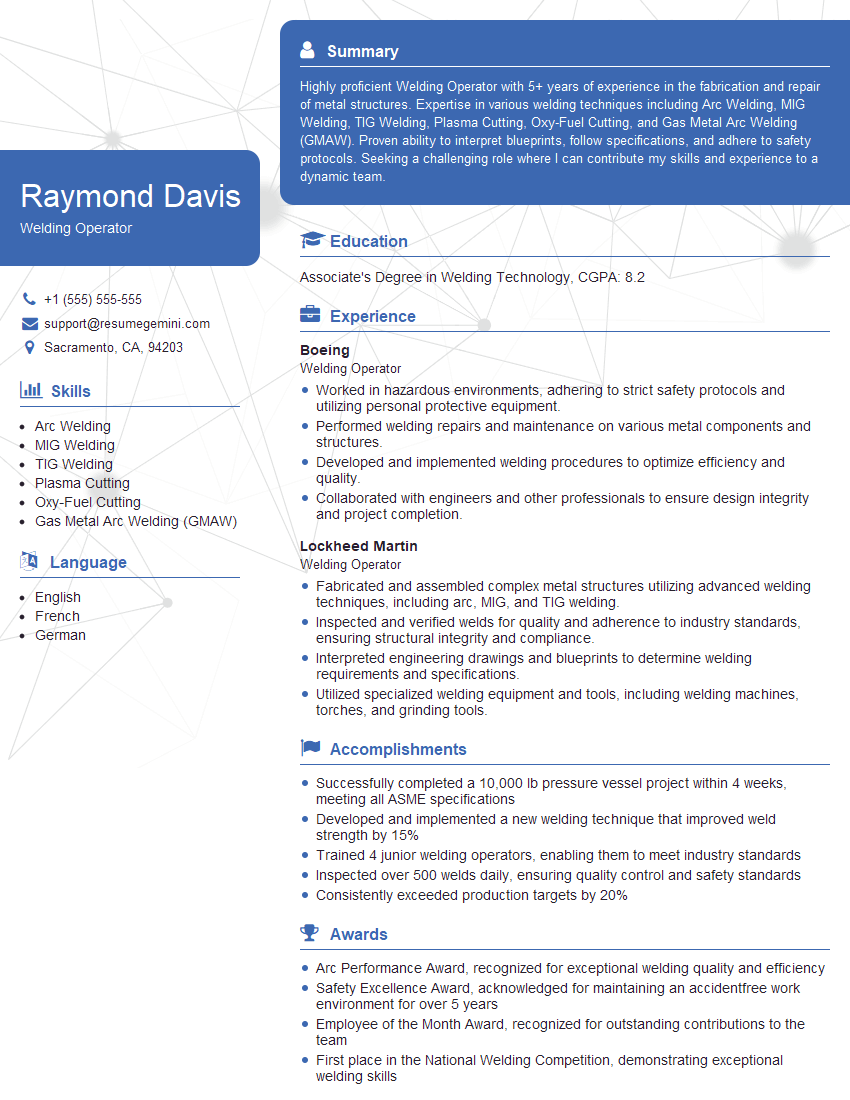

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Welding Operator

1. What are the different welding processes you are familiar with?

- Arc welding (e.g., TIG, MIG, stick) involves using an electric arc to create heat for welding.

- Gas welding involves using a fuel gas, such as acetylene or propane, to create heat for welding.

- Laser welding involves using a high-powered laser to create heat for welding.

- Resistance welding involves using heat generated by electrical resistance to weld materials.

2. What are the key factors to consider when selecting a welding process for a particular application?

Material thickness

- Thicker materials require more heat input, which may necessitate a higher-powered welding process.

Material type

- Different materials have varying welding characteristics, and some processes are better suited for certain materials.

Joint design

- The shape and orientation of the joint can impact the choice of welding process.

Welding environment

- Factors such as accessibility, ventilation, and safety regulations may influence the selection of a welding process.

3. How do you ensure the quality of your welds?

- Proper preparation of the welding area, including cleaning and joint preparation

- Using the correct welding process and parameters for the materials and joint

- Visual inspection of the weld to check for defects

- Non-destructive testing, such as radiography or ultrasonic testing, to verify weld integrity

4. What is the difference between pre-heat and post-heat in welding?

- Pre-heat involves heating the base metal before welding to reduce the risk of cracking and improve weldability.

- Post-heat involves heating the weld after welding to relieve stresses and improve mechanical properties.

5. What safety precautions do you take when welding?

- Wearing appropriate personal protective equipment (PPE), such as gloves, eye protection, and a welding helmet

- Ensuring proper ventilation to prevent exposure to welding fumes

- Keeping the work area clean and free of tripping hazards

- Storing and handling welding equipment safely

6. What types of welds are commonly used in structural steel fabrication?

- Butt welds

- Fillet welds

- Edge welds

- T-joints

- Corner joints

7. How do you determine the proper weld size for a given application?

- Consider the load-bearing requirements of the joint.

- Refer to welding codes and standards for guidance.

- Use weld size calculators or charts to determine the minimum required weld size.

8. What are the common welding defects and how can they be prevented?

Porosity

- Caused by trapped gases in the weld metal.

- Prevention: Ensure proper shielding gas coverage and avoid welding in windy conditions.

Incomplete fusion

- Caused by insufficient melting of the base metal during welding.

- Prevention: Use proper welding parameters and ensure the joint is properly prepared.

Undercut

- Caused by excessive melting of the base metal adjacent to the weld.

- Prevention: Use proper welding parameters and avoid excessive heat input.

9. How do you troubleshoot welding problems?

- Identify the symptoms of the problem, such as poor weld quality or equipment malfunction.

- Check for common causes, such as incorrect welding parameters, faulty equipment, or improper filler metal.

- Use diagnostic tools or refer to manufacturer’s manuals to pinpoint the issue.

- Implement corrective actions to resolve the problem and prevent recurrence.

10. What are the latest advancements in welding technology that you are aware of?

- Robotic welding for increased productivity and precision

- Laser welding for high-speed, low-distortion applications

- Hybrid welding techniques that combine multiple welding processes for improved weld quality

- Advanced welding inspection techniques using non-destructive testing and artificial intelligence

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Welding Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Welding Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Welding Operators are responsible for joining or cutting metal pieces using various welding techniques and equipment.

1. Welding

Weld metal pieces together using arc welding, gas welding, or other welding methods.

- Follow blueprints and specifications to determine welding procedures.

- Inspect welded joints to ensure quality and meet standards.

2. Cutting

Cut metal pieces using plasma cutting, oxy-fuel cutting, or other cutting methods.

- Operate and adjust welding equipment to achieve desired results.

- Maintain welding equipment and work area in a clean and safe condition.

3. Fabrication

Fabricate metal structures and components according to specifications.

- Assemble and fit metal components using welding and other techniques.

- Interpret technical drawings and blueprints to understand project requirements.

4. Safety

Follow safety procedures and regulations to prevent accidents and injuries.

- Wear protective gear such as welding helmets, gloves, and aprons.

- Inspect equipment regularly and report any defects or hazards.

Interview Tips

Preparing for a Welding Operator interview requires a combination of technical knowledge and presentation skills.

1. Research the Company and Position

Gather information about the company’s industry, products, and specific requirements for the Welding Operator position.

- Visit the company’s website and review job descriptions.

- Look for articles or news about the company and its recent projects.

2. Practice Your Welding Skills

Ensure your welding skills are up-to-date and demonstrate your proficiency during the interview.

- Practice different welding techniques and be prepared to discuss your experience.

- Bring samples of your work to showcase your craftsmanship.

3. Prepare Your Answers

Anticipate common interview questions and prepare thoughtful answers that highlight your qualifications.

- Describe your experience with different welding methods and materials.

- Explain how you ensure the accuracy and quality of your welds.

- Discuss your knowledge of safety protocols and industry standards.

4. Dress Professionally and Arrive on Time

Make a positive impression by dressing appropriately and arriving at the interview on time.

- Wear clean, comfortable, and modest clothing that covers your skin.

- Arrive at the interview location early to allow time for any unexpected delays.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Welding Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!