Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Annealing Furnace Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Annealing Furnace Tender so you can tailor your answers to impress potential employers.

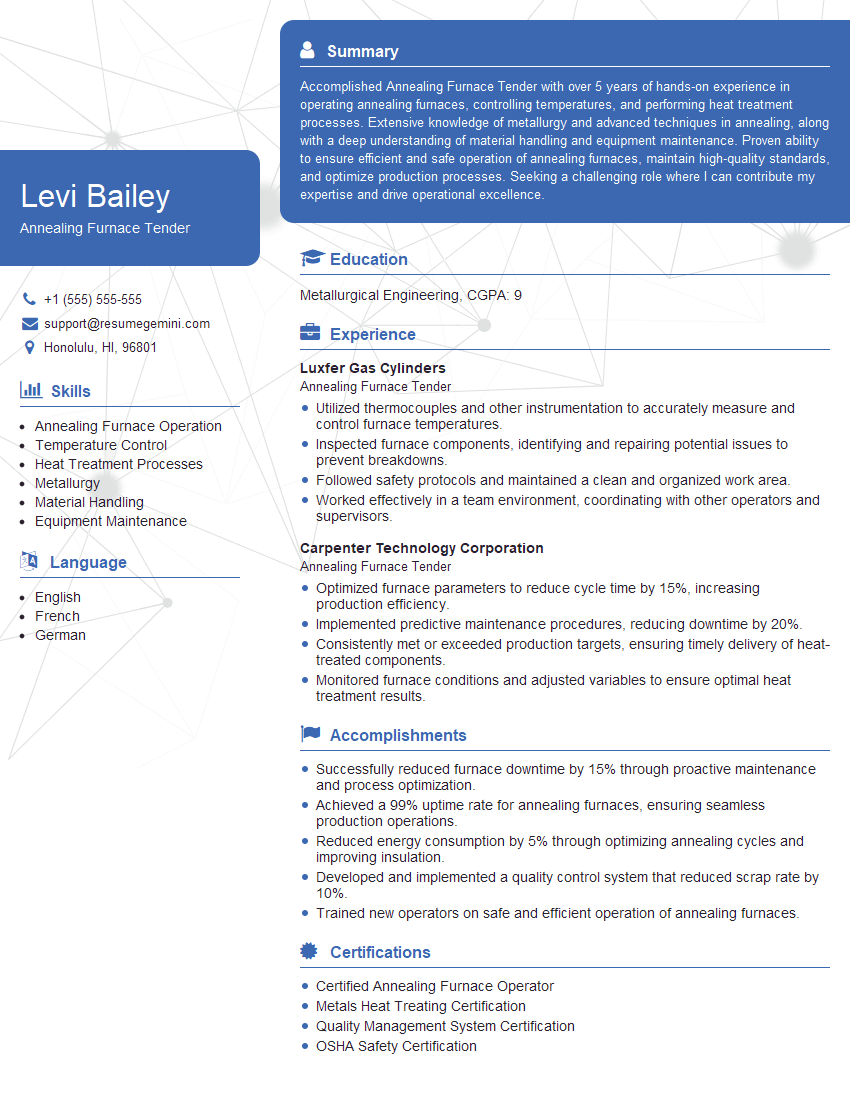

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Annealing Furnace Tender

1. Describe the annealing process, including its purpose and how it is achieved?

- Annealing is a heat treatment process that involves heating a metal to a specific temperature, holding it there for a period of time, and then cooling it slowly.

- The purpose of annealing is to soften the metal, reduce its hardness and brittleness, and improve its ductility and toughness.

- Annealing is achieved by heating the metal to a temperature above its recrystallization temperature, holding it at that temperature for a period of time (soaking time) to allow the grain structure to recrystallize, and then cooling it slowly to room temperature.

2. What types of furnace are used for annealing?

- Continuous furnaces:

- These are used for high-volume production annealing.

- The metal is passed through the furnace on a conveyor belt, and the temperature is controlled to achieve the desired annealing results.

- Batch furnaces:

- These are used for smaller-volume production annealing.

- The metal is placed in the furnace in batches, and the temperature is controlled to achieve the desired annealing results.

- Vacuum furnaces:

- These are used for annealing metals that are sensitive to oxidation or contamination.

- The metal is placed in a vacuum chamber, and the temperature is controlled to achieve the desired annealing results.

3. What are the key parameters to control during annealing process?

- Temperature:

- The temperature must be controlled to achieve the desired annealing results.

- If the temperature is too low, the annealing will not be effective.

- If the temperature is too high, the metal may become damaged.

- Soaking time:

- The soaking time is the amount of time that the metal is held at the annealing temperature.

- The soaking time must be long enough to allow the grain structure to recrystallize.

- If the soaking time is too short, the annealing will not be effective.

- Cooling rate:

- The cooling rate is the rate at which the metal is cooled after annealing.

- The cooling rate must be controlled to achieve the desired annealing results.

- If the cooling rate is too fast, the metal may become hard and brittle.

- If the cooling rate is too slow, the annealing will not be effective.

4. How do you monitor and control the furnace temperature?

- The furnace temperature is monitored using a thermocouple or another temperature-sensing device.

- The temperature is controlled using a temperature controller, which adjusts the heat input to the furnace to maintain the desired temperature.

- The temperature controller may be a manual controller, a programmable controller, or a computer-based controller.

5. What are the safety procedures you follow when operating an annealing furnace?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a lab coat.

- Ensure that the furnace is properly ventilated to remove any hazardous fumes.

- Never touch the hot parts of the furnace.

- Be aware of the location of the fire extinguisher and know how to use it.

- Follow all written safety procedures.

6. How do you troubleshoot common problems that may occur during annealing?

- If the metal is not annealing properly, check the temperature, soaking time, and cooling rate.

- If the furnace is not heating up properly, check the power supply, the heating element, and the temperature controller.

- If the furnace is overheating, check the temperature controller and the cooling system.

- If there is a problem with the vacuum system, check the vacuum pump, the vacuum lines, and the vacuum chamber.

7. What are the different types of annealing?

- Full annealing:

- This is the most common type of annealing.

- The metal is heated to a temperature above its critical temperature, held at that temperature for a period of time, and then cooled slowly.

- Process annealing:

- This is used to soften metal that has been cold worked.

- The metal is heated to a temperature below its critical temperature, held at that temperature for a period of time, and then cooled slowly.

- Stress relieving:

- This is used to relieve stresses in metal that has been subjected to mechanical or thermal stresses.

- The metal is heated to a temperature below its critical temperature, held at that temperature for a period of time, and then cooled slowly.

8. What are the benefits of annealing?

- Annealing can soften metal, reduce its hardness and brittleness, and improve its ductility and toughness.

- Annealing can also relieve stresses in metal, improve its machinability, and make it more resistant to corrosion.

9. What are the different types of metals that can be annealed?

- Annealing can be used on a wide variety of metals, including steel, aluminum, copper, and brass.

- The annealing process will vary depending on the type of metal being annealed.

10. What are the applications of annealing?

- Annealing is used in a wide variety of applications, including:

- Automotive industry:

- Annealing is used to soften steel for use in car bodies and other components.

- Aerospace industry:

- Annealing is used to soften aluminum for use in aircraft components.

- Electronics industry:

- Annealing is used to soften copper for use in electrical wires and cables.

- Medical industry:

- Annealing is used to soften stainless steel for use in surgical instruments.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Annealing Furnace Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Annealing Furnace Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Annealing Furnace Tenders play a crucial role in maintaining the optimal functioning of annealing furnaces, ensuring the proper heat treatment of metal products. Their key responsibilities include:

1. Furnace Operation and Monitoring

Operate and monitor annealing furnaces to maintain precise temperature and atmosphere conditions required for metal treatment.

- Control furnace temperature using thermocouples and other instruments.

- Adjust gas flow and atmosphere to achieve the desired chemical composition.

2. Material Handling

Load, unload, and transport metal products to and from the annealing furnace.

- Use cranes, forklifts, or manual equipment to move heavy materials.

- Inspect materials before and after annealing to ensure quality.

3. Quality Control

Monitor and inspect annealed products to ensure they meet specifications.

- Perform hardness tests and other quality checks.

- Maintain records and document quality control data.

4. Maintenance and Repair

Perform basic maintenance and repair on annealing furnaces and associated equipment.

- Clean and lubricate moving parts.

- Replace filters and other consumable items.

5. Safety Compliance

Adhere to all safety regulations and procedures related to furnace operation.

- Wear appropriate protective gear and follow lockout-tagout procedures.

- Monitor work area for potential hazards.

Interview Tips

Preparing for an interview for an Annealing Furnace Tender position requires a combination of research, practice, and confidence. Here are some valuable tips to help you ace the interview:

1. Research the Company and Position

Learn about the company, its products or services, and the specific requirements of the Annealing Furnace Tender role. This will help you tailor your answers to the interviewer’s questions.

2. Practice Your Answers

Anticipate common interview questions related to the key responsibilities of the job. Prepare clear and concise answers that highlight your skills, experience, and knowledge.

3. Emphasize Your Technical Skills

Annealing Furnace Tenders require strong technical skills. Highlight your ability to operate and monitor furnaces, handle materials safely, and perform quality control checks.

4. Showcase Your Safety Consciousness

Safety is paramount in furnace operations. Emphasize your commitment to adhering to safety regulations and procedures, and share any relevant examples from your previous experience.

5. Be Enthusiastic and Professional

Demonstrate your enthusiasm for the role and the industry. Show the interviewer that you are eager to learn and contribute to the team.

6. Prepare Questions for the Interviewer

Ask thoughtful questions at the end of the interview to show your interest and engagement. This also gives you a chance to clarify any aspects of the role or company.

Next Step:

Now that you’re armed with the knowledge of Annealing Furnace Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Annealing Furnace Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini