Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Case Hardener position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

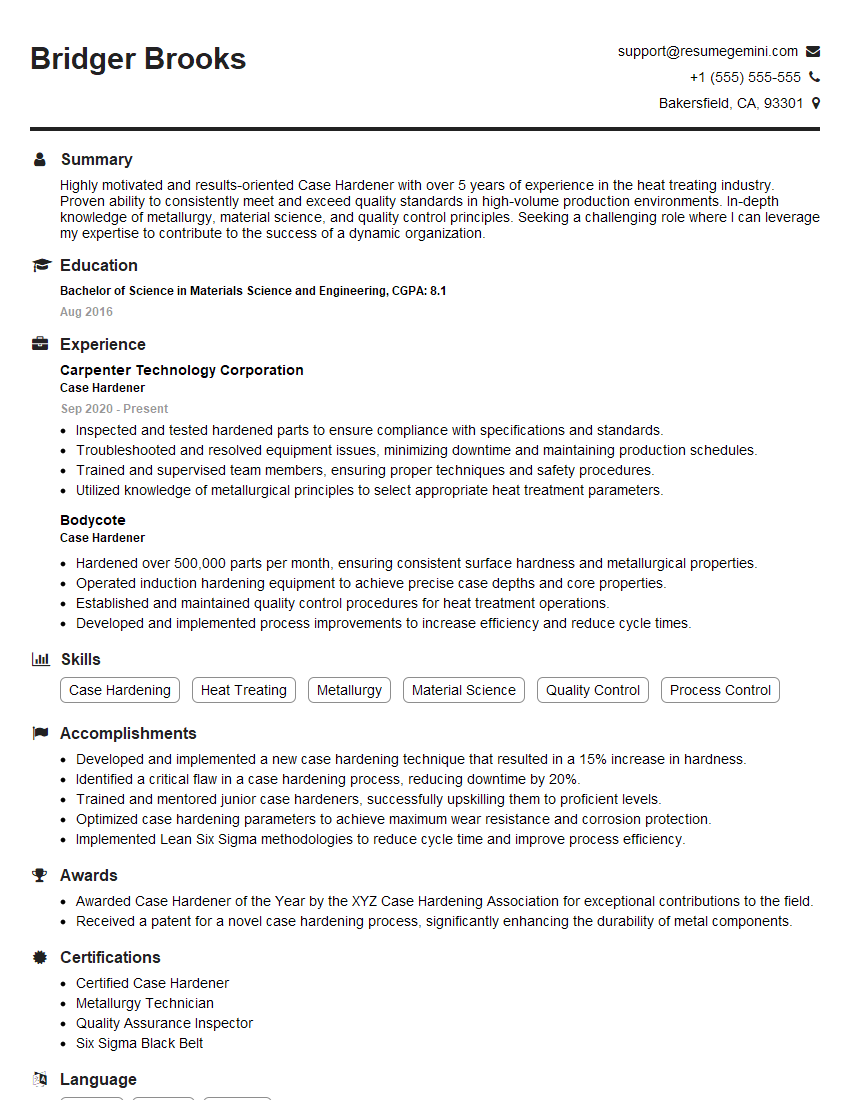

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Case Hardener

1. What is case hardening and why is it important?

- Case hardening is a metalworking process in which the surface of a metal is hardened while the core remains soft and ductile.

- This process is used to improve the wear resistance, strength, and durability of metal components.

- It is particularly important for components that are subjected to high levels of stress and wear, such as gears, bearings, and cutting tools.

2. 2. What are the different methods of case hardening?

carbide method

- Carburizing is a process in which the surface of a metal is exposed to a carbon-rich atmosphere at high temperature.

- This causes carbon atoms to diffuse into the surface of the metal, forming a hard, wear-resistant layer.

- Commonly used for components that require high surface hardness and wear resistance.

nitride method

- Nitriding is a process in which the surface of a metal is exposed to a nitrogen-rich atmosphere at high temperature.

- This causes nitrogen atoms to diffuse into the surface of the metal, forming a hard, wear-resistant layer that is also corrosion resistant.

- Suitable for components that require high surface hardness, wear resistance, and corrosion resistance.

3. What are the advantages and disadvantages of case hardening?

- Advantages:

- Increased surface hardness and wear resistance

- Improved strength and durability

- Reduced distortion and cracking

- Cost-effective compared to through-hardening

- Disadvantages:

- Can be a complex and time-consuming process

- Requires specialized equipment and expertise

- May not be suitable for all types of components or materials

4. What are the different factors that affect the depth of case hardening?

- Temperature

- Time

- Atmosphere composition

- Material composition

- Surface condition

5. How do you test the quality of case hardened components?

- Visual inspection

- Hardness testing

- Microstructure analysis

- Wear testing

- Fatigue testing

6. What are the common problems encountered in case hardening and how do you solve them?

- Problem: Distortion

- Solution: Proper fixturing, stress relieving, or using a lower hardening temperature.

- Problem: Cracking

- Solution: Proper preheating, avoiding sharp corners, or using a lower hardening temperature.

- Problem: Insufficient case depth

- Solution: Increase hardening time, temperature, or atmosphere concentration.

- Problem: Excessive case depth

- Solution: Decrease hardening time, temperature, or atmosphere concentration.

- Problem: Soft core

- Solution: Increase core hardening temperature, time, or use a higher alloy steel.

7. What are the latest advancements in case hardening technology?

- Laser case hardening

- Plasma case hardening

- Ion implantation

- Pack carburizing

- Vacuum carburizing

8. How do you stay updated on the latest case hardening techniques?

- Attending industry conferences and workshops

- Reading technical journals and articles

- Networking with other case hardening professionals

- Conducting in-house research and development

9. What are the safety precautions that should be taken when case hardening?

- Wear appropriate personal protective equipment (PPE)

- Ensure proper ventilation

- Handle hazardous materials safely

- Follow established safety protocols

- Be aware of potential hazards and take appropriate measures to mitigate them

10. What are the quality standards that apply to case hardening?

- ASTM A370: Standard Test Methods and Definitions for Mechanical Testing of Steel Products

- ASTM E10: Standard Test Method for Brinell Hardness of Metallic Materials

- ASTM E18: Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials

- ISO 6508-1: Metallic materials – Rockwell hardness test – Part 1: Test method

- ISO 6507-1: Metallic materials – Vickers hardness test – Part 1: Test method

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Case Hardener.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Case Hardener‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Case Hardening is a process of surface hardening of ferrous metals to increase its strength and durability. Case Hardeners are responsible for carrying out this process and ensuring the quality of the hardened metal parts.

1. Case Hardening Process

Carry out the case hardening processes, including carburizing, nitriding, and induction hardening, to achieve the desired surface properties.

- Monitor and control furnace temperatures, gas flow rates, and other process parameters to ensure adherence to specifications.

- Interpret blueprints and technical drawings to determine case hardening requirements.

2. Equipment Operation and Maintenance

Operate and maintain case hardening equipment, including furnaces, quenching tanks, and other machinery.

- Calibrate and maintain equipment to ensure accuracy and reliability.

- Troubleshoot and resolve equipment malfunctions to minimize downtime.

3. Quality Control

Conduct quality control checks on hardened parts to ensure they meet specifications.

- Perform visual inspections, hardness testing, and other quality control procedures.

- Maintain records and documentation of quality control checks.

4. Safety and Environmental Compliance

Follow all safety and environmental regulations related to case hardening operations.

- Wear appropriate personal protective equipment (PPE) and adhere to safety protocols.

- Monitor and control emissions and waste disposal to comply with environmental regulations.

Interview Tips

Preparing for a case hardening interview requires a combination of technical knowledge, industry experience, and effective communication skills. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends. This will demonstrate your interest and knowledge of the field.

- Visit the company’s website to learn about their mission, values, and recent developments.

- Read industry publications and attend webinars to stay updated with the latest technologies and practices.

2. Highlight Your Technical Skills

Emphasize your expertise in case hardening techniques, equipment operation, and quality control procedures.

- Provide specific examples of projects where you successfully applied your skills to achieve desired results.

- Quantify your accomplishments using metrics such as improved product quality, reduced downtime, or increased efficiency.

3. Showcase Your Problem-Solving Abilities

Describe situations where you encountered challenges in case hardening operations and how you resolved them effectively.

- Explain your analytical approach to troubleshooting and identifying root causes.

- Highlight your ability to think critically and implement solutions that improve processes.

4. Emphasize Safety and Environmental Awareness

Explain your commitment to workplace safety and environmental compliance in case hardening operations.

- Discuss your knowledge of relevant regulations and industry best practices.

- Share examples of how you have implemented safety and environmental measures in your previous roles.

5. Practice Your Communication Skills

Case hardening requires effective communication with engineers, supervisors, and customers. Practice answering common interview questions clearly and concisely.

- Prepare answers to questions about your experience, skills, and career goals.

- Ask thoughtful questions to demonstrate your engagement and interest in the position.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Case Hardener, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Case Hardener positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.