Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Flame Hardener position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

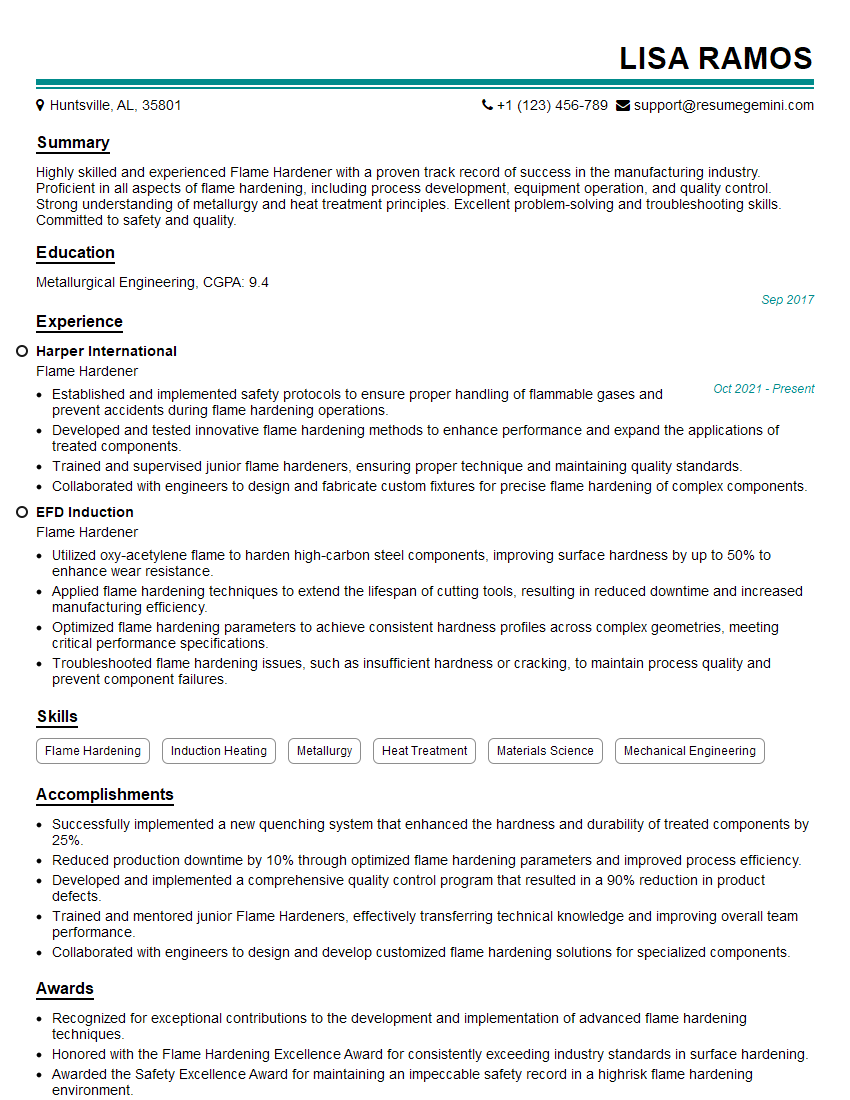

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flame Hardener

1. What are the key factors to consider when selecting a flame hardening process for a particular application?

- The desired surface hardness and case depth

- The material being hardened

- The geometry of the part

- The production volume

- The cost

2. What are the different types of flame hardening processes?

Oxy-acetylene flame hardening

- Uses an oxy-acetylene torch to heat the surface of the metal

- Produces a thin, hard case

- Suitable for small parts

Induction flame hardening

- Uses an induction coil to generate heat in the metal

- Produces a deep, hard case

- Suitable for large parts

Laser flame hardening

- Uses a laser to heat the surface of the metal

- Produces a very thin, hard case

- Suitable for very small parts

3. What are the advantages and disadvantages of flame hardening?

Advantages:

- Can be used to harden a wide variety of metals

- Produces a hard, wear-resistant surface

- Improves the fatigue strength of the metal

- Relatively low cost

Disadvantages:

- Can cause distortion of the part

- Can produce a brittle surface

- Requires skilled operators

4. What are the safety precautions that must be taken when flame hardening?

- Wear appropriate personal protective equipment (PPE), including a hard hat, safety glasses, gloves, and earplugs

- Keep the work area clean and free of flammable materials

- Use proper ventilation to remove fumes

- Have a fire extinguisher nearby

- Never leave the flame unattended

5. What are some of the common applications of flame hardening?

- Gears

- Bearings

- Shafts

- Cutting tools

- Automotive parts

6. What are the different types of flame hardening equipment?

- Manual flame hardening torches

- Automated flame hardening machines

- Induction flame hardening machines

- Laser flame hardening machines

7. What are the different types of flame hardening consumables?

- Fuel gases (e.g., oxy-acetylene, propane)

- Oxidizing gases (e.g., oxygen, air)

- Shield gases (e.g., argon, helium)

- Quenching media (e.g., water, oil)

8. What are the different types of flame hardening defects?

- Distortion

- Brittleness

- Cracking

- Spalling

- Oxidation

9. What are the different ways to prevent flame hardening defects?

- Use proper preheating and postheating techniques

- Control the flame temperature and heating time

- Use proper quenching media

- Inspect parts after flame hardening for any defects

10. What are the different ways to test the quality of flame hardened parts?

- Hardness testing

- Microstructure examination

- Fatigue testing

- Wear testing

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flame Hardener.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flame Hardener‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Flame Hardener is responsible for hardening metal surfaces using a flame hardening process. This process involves heating the surface of the metal to a high temperature and then rapidly cooling it to increase its hardness and wear resistance. Key job responsibilities of a Flame Hardener include:

1. Preparing the metal surface

Before flame hardening, the metal surface must be cleaned and prepared to ensure proper bonding between the hardened layer and the base metal.

- Cleaning the surface to remove any dirt, oil, or other contaminants.

- Masking off areas that should not be hardened.

2. Selecting the appropriate flame hardening process

There are different flame hardening processes, such as progressive hardening and spot hardening. The appropriate process depends on the desired hardness, depth of hardening, and geometry of the workpiece.

- Understanding the different flame hardening processes and their applications.

- Selecting the correct flame hardening process for the specific job requirements.

3. Operating the flame hardening equipment

Flame hardening involves using specialized equipment, such as oxy-acetylene torches or induction heating systems.

- Setting up and operating the flame hardening equipment safely and efficiently.

- Controlling the flame temperature, heating time, and cooling rate to achieve the desired hardness.

4. Inspecting the hardened surface

After flame hardening, the surface must be inspected to ensure it meets the desired hardness and quality standards.

- Conducting visual inspections and hardness testing to verify the hardness and integrity of the hardened surface.

- Identifying and correcting any defects or inconsistencies in the hardened surface.

5. Maintaining and calibrating equipment

Regular maintenance and calibration of flame hardening equipment are crucial to ensure accuracy and safety.

- Performing routine maintenance and calibration of the flame hardening equipment according to manufacturer’s instructions.

- Maintaining a clean and organized work area to minimize potential hazards.

Interview Tips

To prepare for an interview as a Flame Hardener, consider the following tips:

1. Research the company and the industry

Familiarize yourself with the company’s history, products, and industry practices. This will help you understand the company’s culture and the specific requirements of the role.

- Visit the company’s website and social media pages to gather information.

- Read industry publications and articles to stay updated on current trends and best practices.

2. Practice answering common interview questions

Prepare for questions related to your technical skills, experience, and knowledge of flame hardening processes. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers.

- Describe a time when you successfully flame hardened a complex or challenging workpiece.

- Explain the different types of flame hardening processes and their applications.

3. Showcase your safety awareness

Flame hardening involves working with high temperatures and potentially hazardous equipment. Emphasize your understanding of safety protocols and your commitment to maintaining a safe work environment.

- Describe your experience with safety procedures and hazard identification.

- Explain how you ensure the safety of yourself and others while operating flame hardening equipment.

4. Highlight your problem-solving abilities

Flame hardening can involve troubleshooting and resolving issues during the process. Demonstrate your ability to analyze problems, identify solutions, and implement effective measures.

- Provide examples of situations where you successfully resolved problems related to flame hardening.

- Explain your approach to identifying and addressing potential challenges.

5. Be enthusiastic and ask questions

Show your passion for flame hardening and your eagerness to learn and contribute to the team. Ask thoughtful questions to demonstrate your interest in the role and the company’s operations.

- Express your interest in the company’s flame hardening practices and how you can contribute to their success.

- Ask about opportunities for professional development and growth within the organization.

Next Step:

Now that you’re armed with the knowledge of Flame Hardener interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Flame Hardener positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini