Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Heat Treater position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

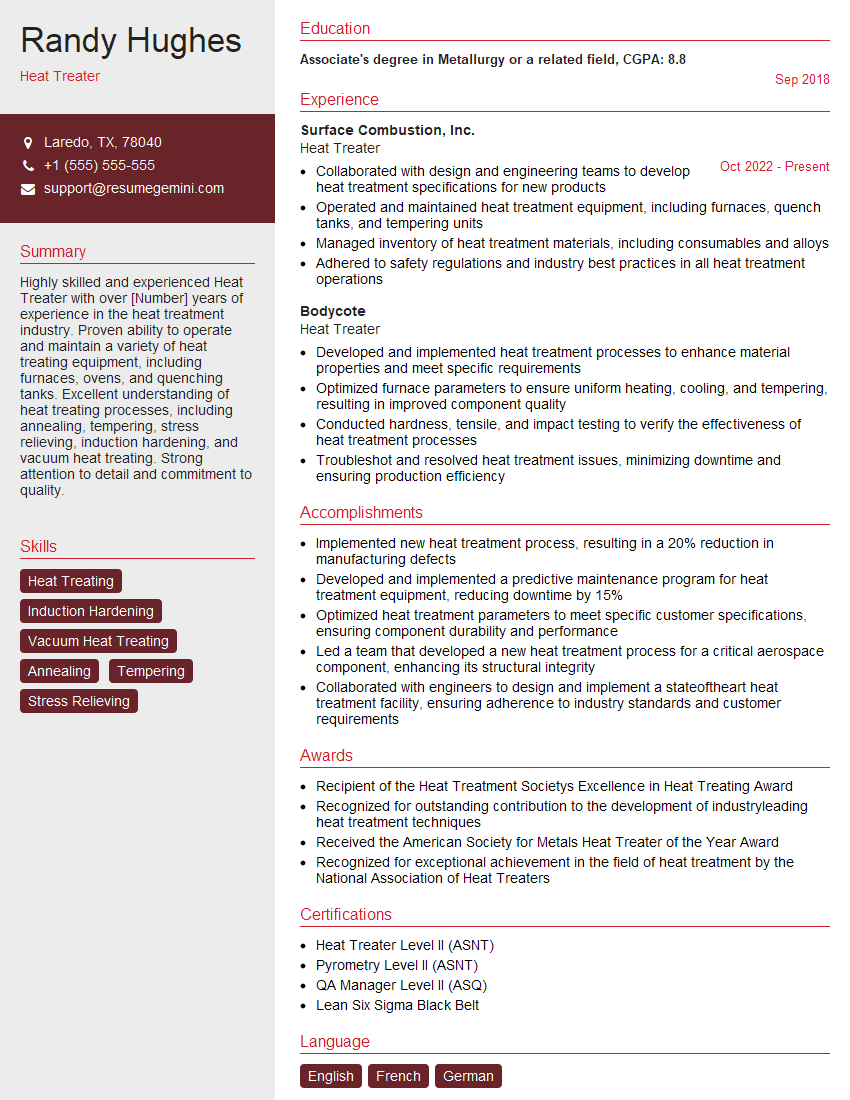

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Heat Treater

1. Describe the steps involved in the heat treatment process?

The heat treatment process typically involves the following steps:

- Preheating: The material is heated to a specified temperature to make it more receptive to the subsequent heat treatment processes.

- Heating: The material is further heated to the desired temperature for the specific heat treatment process being performed.

- Soaking: The material is held at the desired temperature for a specified amount of time to allow the desired changes to occur.

- Cooling: The material is cooled at a controlled rate to achieve the desired properties.

- Tempering: For some types of heat treatment, the material is heated to a lower temperature and then cooled to further enhance the desired properties.

2. Explain the purpose of tempering?

Tempering is a heat treatment process used to improve the toughness, ductility, and impact strength of hardened steel. It is performed by heating the steel to a temperature below its critical temperature and then cooling it at a controlled rate. This process helps to relieve internal stresses, reduce brittleness, and improve the overall mechanical properties of the steel.

3. What are the different types of heat treatment furnaces?

There are various types of heat treatment furnaces used for different applications, including:

- Batch furnaces: These furnaces are used for heat treating small batches of parts in a chamber.

- Continuous furnaces: These furnaces are used for high-volume production, where parts are continuously fed through the furnace.

- Vacuum furnaces: These furnaces are used for heat treating materials in a vacuum environment to prevent oxidation and contamination.

- Salt bath furnaces: These furnaces use molten salt baths as the heating medium for uniform and precise temperature control.

- Induction furnaces: These furnaces use electromagnetic induction to heat materials, providing fast and localized heating.

4. What are the key factors to consider when selecting a heat treatment process?

When selecting a heat treatment process, several key factors should be considered:

- Material properties: The composition and properties of the material being treated.

- Desired properties: The specific properties that need to be achieved, such as hardness, strength, toughness, or wear resistance.

- Equipment capabilities: The availability and capabilities of the heat treatment equipment.

- Production requirements: The volume and production rate required.

- Cost considerations: The cost of the heat treatment process and its impact on overall manufacturing costs.

5. How do you ensure the quality of heat-treated parts?

To ensure the quality of heat-treated parts, several measures can be implemented:

- Process control: Establishing and following standardized heat treatment procedures for each type of material and application.

- Temperature monitoring: Using accurate and calibrated temperature sensors to monitor and control the temperature throughout the heat treatment process.

- Hardness testing: Performing hardness tests on samples or finished parts to verify that the desired hardness is achieved.

- Metallurgical testing: Analyzing the microstructure and properties of heat-treated parts using techniques like microscopy or mechanical testing to ensure they meet the specifications.

- Quality management system: Implementing and maintaining a quality management system to track and control the entire heat treatment process.

6. What are the common defects that can occur during heat treatment?

Several defects can occur during heat treatment, including:

- Overheating: Heating the material to a temperature above its recommended limits, which can cause grain growth, reduced strength, and embrittlement.

- Underheating: Heating the material to a temperature below its recommended limits, which can result in insufficient property changes and may require additional heat treatment.

- Quenching cracks: Developing cracks in the material due to rapid cooling during the quenching process.

- Warpage: Distortion or bending of the material due to uneven heating or cooling, residual stresses, or material properties.

- Decarburization: Loss of carbon from the surface of the material due to exposure to an oxidizing atmosphere during heat treatment.

7. How do you prevent or minimize defects during heat treatment?

To prevent or minimize defects during heat treatment, several measures can be taken:

- Proper process control: Following established heat treatment procedures and maintaining accurate temperature control.

- Material selection: Choosing materials that are suitable for the intended heat treatment process and application.

- Preheating and post-heating: Gradual heating and cooling to minimize thermal stresses and prevent warpage.

- Proper quenching: Selecting appropriate quenching media and methods based on material properties and desired properties.

- Stress relief: Performing stress relief treatments to reduce residual stresses and improve toughness.

8. What are the latest advancements in heat treatment technology?

The field of heat treatment is constantly evolving, with new technologies and advancements emerging:

- Advanced induction heating: Using high-frequency induction heating systems for precise and localized heating.

- Vacuum heat treatment: Utilizing vacuum furnaces for clean and controlled heat treatment environments.

- Computer modeling and simulation: Employing software to simulate and optimize heat treatment processes.

- Laser heat treatment: Using lasers for localized, rapid heating and surface hardening.

- Nanotechnology: Incorporating nanoparticles and other nanomaterials to enhance heat treatment outcomes.

9. Describe your experience in troubleshooting heat treatment issues?

In my previous roles, I have encountered various heat treatment issues and implemented effective troubleshooting strategies:

- Identifying root causes: Analyzing process parameters, material properties, and equipment performance to determine the source of the problem.

- Modifying heat treatment parameters: Adjusting temperature, time, and cooling rates based on technical data and experience.

- Equipment maintenance: Performing regular inspections and maintenance on heat treatment furnaces and related equipment.

- Material testing: Conducting hardness testing, microstructure analysis, and mechanical testing to evaluate the results of troubleshooting efforts.

- Collaboration with vendors and experts: Consulting with heat treatment equipment manufacturers and material suppliers to seek technical advice and support.

10. How do you stay updated with the latest developments in heat treatment?

To stay abreast of the latest advancements in heat treatment, I actively engage in the following activities:

- Industry conferences and exhibitions: Attending industry events to learn about new technologies, research findings, and best practices.

- Technical publications and journals: Reading technical articles, white papers, and case studies to stay informed about recent developments in the field.

- Online resources: Exploring websites, forums, and databases dedicated to heat treatment for up-to-date information and knowledge sharing.

- Collaboration with experts: Engaging with heat treatment professionals, researchers, and industry leaders to exchange ideas and learn about emerging technologies.

- Continuing education: Pursuing professional development opportunities, such as workshops, webinars, and online courses, to expand my knowledge and skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Heat Treater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Heat Treater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Heat Treaters are responsible for a wide range of tasks that are critical to the manufacturing process. Their key responsibilities include:Ensuring that metal parts meet the required hardness and strength specifications.

1. Heat Treatment Processes

Conducting heat treatment processes such as annealing, normalizing, tempering, and hardening.

- Understanding the different types of heat treatment processes and their effects on metal properties.

- Selecting the appropriate heat treatment process for different types of metals and applications.

2. Equipment Operation and Maintenance

Operating and maintaining heat treatment equipment, including furnaces, ovens, and quenching tanks.

- Monitoring and controlling the temperature, pressure, and other operating parameters of heat treatment equipment.

- Performing preventive maintenance and repairs on heat treatment equipment to ensure its proper functioning.

3. Quality Control and Testing

Performing quality control tests on heat-treated parts to ensure they meet specifications.

- Conducting hardness tests, tensile tests, and other quality control tests to evaluate the properties of heat-treated parts.

- Analyzing test results and making adjustments to heat treatment processes as needed.

4. Safety and Compliance

Adhering to safety regulations and procedures related to heat treatment processes.

- Wearing appropriate personal protective equipment (PPE) when operating heat treatment equipment.

- Following established safety protocols to prevent accidents and injuries.

Interview Tips

To ace an interview for a Heat Treater position, candidates should prepare thoroughly and highlight their skills and experience in the following areas:

1. Technical Expertise

Demonstrate a strong understanding of heat treatment processes, equipment, and materials.

- Be prepared to discuss different types of heat treatment processes, their effects on metal properties, and their applications.

- Highlight your knowledge of heat treatment equipment, including furnaces, ovens, and quenching tanks.

2. Quality Control and Testing

Emphasize your experience in performing quality control tests and evaluating heat-treated parts.

- Describe your proficiency in conducting hardness tests, tensile tests, and other quality control tests.

- Explain your approach to analyzing test results and making adjustments to heat treatment processes as needed.

3. Safety and Compliance

Convey your commitment to safety and compliance in the workplace.

- Discuss your adherence to safety regulations and procedures related to heat treatment processes.

- Highlight your experience in wearing appropriate PPE and following established safety protocols.

4. Communication and Teamwork

Express your ability to work effectively in a team environment and communicate clearly.

- Provide examples of your experience collaborating with other team members to achieve common goals.

- Demonstrate your strong communication skills by clearly and concisely explaining heat treatment processes and procedures.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Heat Treater role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.