Are you gearing up for a career in Heat Treating Furnace Tender? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Heat Treating Furnace Tender and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

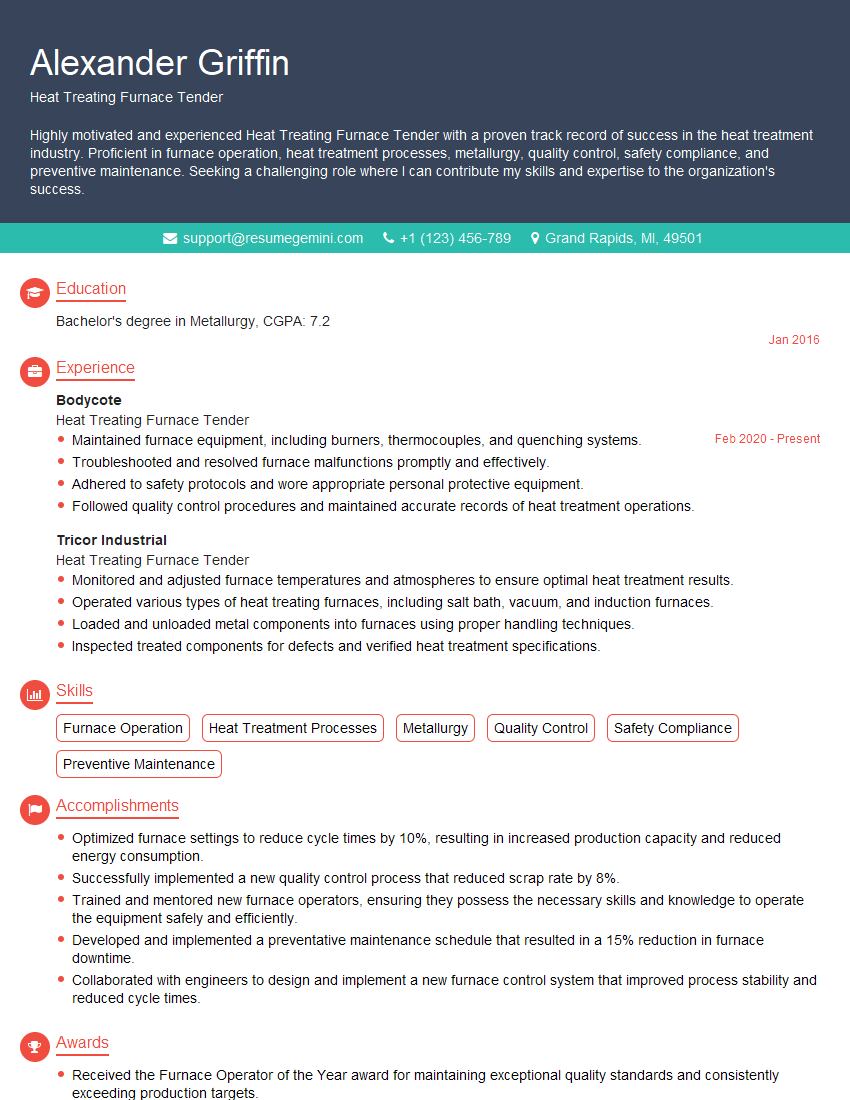

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Heat Treating Furnace Tender

1. Explain the process of heat treating metals?

Heat treating metals involves controlled heating and cooling of the metal to achieve desired properties or characteristics. The process can be divided into several steps:

- Annealing: Heating the metal to a specific temperature and then slowly cooling it to soften it and improve its ductility.

- Quenching: Rapidly cooling the metal by immersing it in water, oil, or air to harden it and increase its strength.

- Tempering: Heating the quenched metal to a lower temperature to reduce its hardness and improve its toughness.

- Stress relieving: Heating the metal to a specific temperature and holding it for a period of time to remove internal stresses.

- Hardening: Heating the metal to a specific temperature and rapidly cooling it to increase its hardness and wear resistance.

2. What are the different types of heat treating furnaces?

There are several types of heat treating furnaces, including:

- Box furnaces: Enclosed furnaces that use electric heating elements or gas burners to heat the metal.

- Pit furnaces: Vertical furnaces in which the metal is placed in a basket and lowered into the furnace.

- Shuttle furnaces: Continuous furnaces that move the metal through the different heating and cooling zones.

- Rotary furnaces: Furnaces that rotate the metal while heating it to ensure uniform heating.

- Vacuum furnaces: Furnaces that operate in a vacuum environment to prevent oxidation and contamination of the metal.

3. What are the key parameters to consider when selecting a heat treating furnace?

- Temperature range: The temperature range that the furnace can achieve.

- Atmosphere: The type of atmosphere (e.g., air, inert gas) in which the metal is heated.

- Heating rate: The rate at which the metal is heated.

- Cooling rate: The rate at which the metal is cooled.

- Furnace capacity: The size and weight of the metal that can be processed in the furnace.

4. How do you monitor and control the heat treating process?

The heat treating process is monitored and controlled using a variety of instruments and techniques, including:

- Thermocouples: Used to measure the temperature of the metal and the furnace.

- Flow meters: Used to measure the flow rate of the gas or air used in the furnace.

- Data loggers: Used to record the process parameters over time.

- Computer-based control systems: Used to automatically control the furnace and record process data.

5. What are the common defects that can occur during heat treating?

- Warping: Distortion of the metal due to uneven heating or cooling.

- Cracking: Formation of cracks in the metal due to excessive stress or improper cooling.

- Decarburization: Loss of carbon from the surface of the metal due to oxidation.

- Overheating: Heating the metal to a temperature that exceeds its recommended limit.

- Underheating: Heating the metal to a temperature that is below its recommended limit.

6. What maintenance checks are required for a heat treating furnace?

Regular maintenance checks are essential to ensure the proper operation and safety of a heat treating furnace. These checks typically include:

- Inspection of the furnace chamber and heating elements: To identify any damage or wear.

- Calibration of thermocouples: To ensure accurate temperature measurement.

- Checking the gas or air supply system: To ensure proper flow and pressure.

- Lubrication of moving parts: To reduce friction and wear.

- Cleaning the furnace chamber and exhaust system: To remove any debris or contamination.

7. What safety precautions are necessary when operating a heat treating furnace?

Operating a heat treating furnace requires strict adherence to safety precautions, including:

- Wearing appropriate personal protective equipment (PPE): Such as heat-resistant gloves, goggles, and protective clothing.

- Ensuring proper ventilation: To remove hazardous fumes and gases.

- Following proper operating procedures: As outlined by the furnace manufacturer.

- Never touching the hot metal or furnace components: To avoid burns or injuries.

- Being aware of potential hazards: Such as fire, explosions, and electrical hazards.

8. Describe your experience with heat treating equipment troubleshooting?

Troubleshooting problems with heat treating equipment requires a systematic approach, which typically involves:

- Identifying the problem: Describe the symptoms and any error messages.

- Checking the equipment: Inspect the equipment, including wiring, connections, and components.

- Consulting with the manufacturer’s documentation: Refer to the user manual or technical support resources.

- Testing the equipment: Perform tests and diagnostics to isolate the problem.

- Repairing or replacing the faulty component: Once the problem is identified, repair or replace the necessary component.

- Verifying the repair: Test the equipment to ensure it is functioning correctly.

9. Explain how you ensure the quality of heat-treated products?

To ensure the quality of heat-treated products, several measures can be implemented:

- Establishing quality control standards: Define the specifications and requirements for the heat-treated products.

- Testing and inspection: Conduct tests, such as hardness testing, to verify the properties of the heat-treated products.

- Process validation: Validate the heat treating process to ensure it consistently meets the quality standards.

- Documentation: Maintain accurate records of the process parameters, test results, and any deviations.

- Continuous improvement: Regularly review the heat treating process and identify areas for improvement.

10. What are your career goals as a Heat Treating Furnace Tender?

As a Heat Treating Furnace Tender, my career goals include:

- Developing expertise: Enhance my technical knowledge and skills in heat treating processes.

- Contributing to the team: Collaborate effectively with colleagues to optimize production and maintain quality.

- Advancing my career: Seek opportunities for professional development and growth within the field of heat treating.

- Staying updated: Keep abreast of the latest advancements and best practices in heat treating technology.

- Providing excellent customer service: Ensure that the heat-treated products meet the customer’s requirements and specifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Heat Treating Furnace Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Heat Treating Furnace Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Heat Treating Furnace Tenders are responsible for operating and maintaining heat treating furnaces used to alter the physical properties of metal components, ensuring they meet specified requirements. Their primary duties include:

1. Furnace Operation

Setting up, operating, and monitoring heat treating furnaces, including adjusting temperature, atmosphere, and quench rates.

2. Material Handling

Loading and unloading metal components into and out of furnaces, using appropriate equipment like forklifts or cranes.

3. Quality Control

Inspecting treated components for defects, hardness, and other quality parameters. Recording and maintaining production data.

4. Equipment Maintenance

Performing routine maintenance on furnaces and related equipment. Troubleshooting and resolving operational issues. Ensuring safe and efficient furnace operation.

Interview Tips

To thoroughly prepare for a Heat Treating Furnace Tender interview, focus on demonstrating your:

1. Technical Proficiency

Highlight your knowledge of heat treating processes, furnace operation, and quality control techniques. Provide examples showcasing your ability to analyze and resolve technical issues.

2. Safety Awareness

Emphasize your understanding of safety protocols in a furnace environment. Discuss your experience in handling hazardous materials, operating equipment, and maintaining a safe work area.

3. Attention to Detail

Stress your ability to follow instructions precisely, monitor processes closely, and identify deviations from specifications. Provide instances where your meticulousness ensured product quality.

4. Communication Skills

Show that you are comfortable communicating with supervisors, colleagues, and clients. Highlight your ability to convey clear instructions, report observations, and resolve queries.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Heat Treating Furnace Tender role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.