Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Induction Machine Setter interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Induction Machine Setter so you can tailor your answers to impress potential employers.

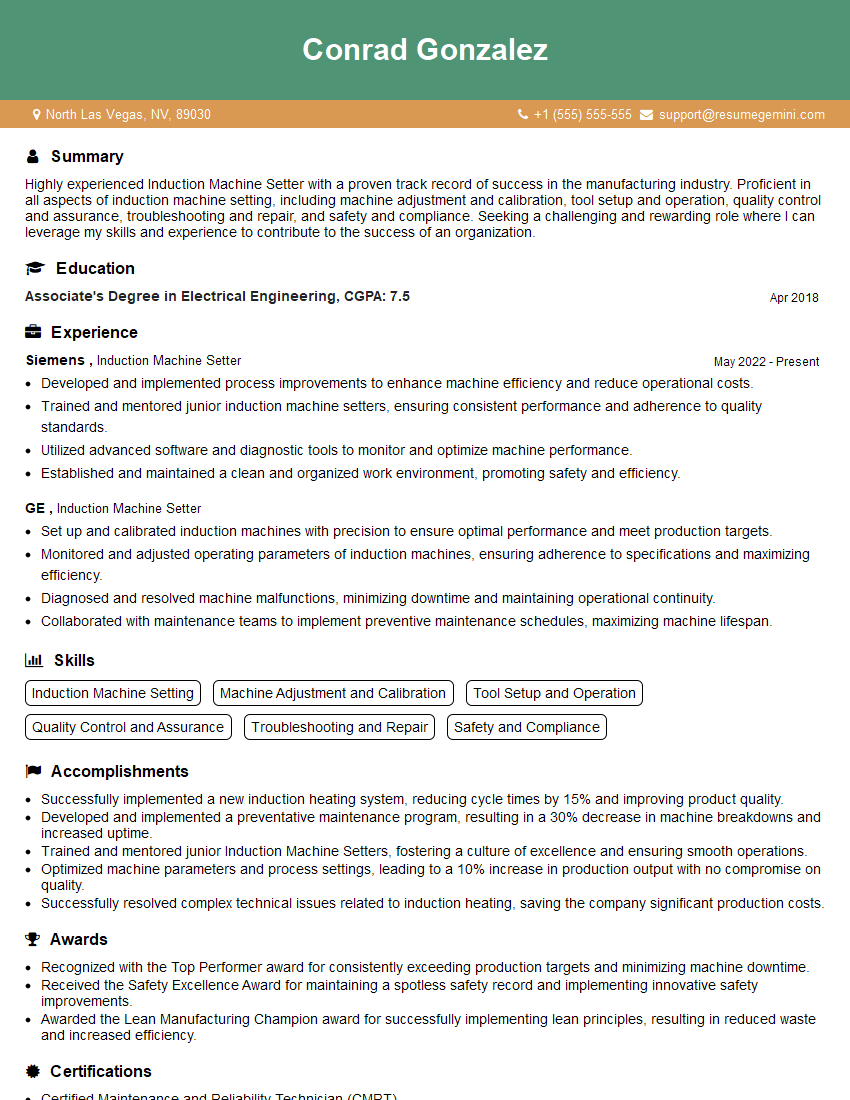

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Induction Machine Setter

1. What is the purpose of an induction machine setter?

An Induction Machine Setter is responsible for setting up, adjusting, and maintaining induction machines.

- They ensure that the machines are operating efficiently and meeting the required specifications.

2. What are the key responsibilities of an induction machine setter?

Setting Up

- Installing and connecting induction motors

- Adjusting the machine’s settings and parameters according to the manufacturer’s specifications

Maintaining

- Performing regular inspections and maintenance tasks to ensure the machine’s proper functioning

- Troubleshooting and resolving any issues that may arise with the machine

Operation

- Monitoring the machine’s performance and making necessary adjustments

- Ensuring that the machine is operating safely and efficiently

3. What are the different types of induction machines?

There are various types of induction machines, each with its own specific characteristics and applications:

- Squirrel-cage induction motors

- Wound-rotor induction motors

- Linear induction motors

- Single-phase induction motors

- Three-phase induction motors

4. What are the factors that affect the performance of an induction machine?

The performance of an induction machine is influenced by several factors, including:

- Load

- Speed

- Voltage

- Temperature

- Machine design

5. What are the common problems that can occur with induction machines?

- Stator winding faults

- Rotor winding faults

- Bearing failures

- Electrical insulation failures

- Mechanical vibration

6. How do you troubleshoot an induction machine?

Safety First

- Ensure the machine is isolated from power and locked out before commencing any troubleshooting process.

Visual Inspection

- Inspect the machine for any obvious signs of damage or wear.

Electrical Tests

- Perform electrical tests such as insulation resistance tests and winding resistance tests to identify any electrical faults.

Mechanical Tests

- Conduct mechanical tests such as vibration analysis and bearing inspections to assess the condition of the machine’s mechanical components.

Data Analysis

- Analyze the data collected from the tests to determine the root cause of the problem and develop a solution.

7. What are the safety precautions that must be observed when working with induction machines?

- Always follow lockout/tagout procedures.

- Wear appropriate personal protective equipment (PPE).

- Ensure the machine is properly grounded.

- Avoid touching any electrical components while the machine is energized.

- Be aware of the potential for rotating parts and pinch points.

8. What are the industry standards and regulations that apply to induction machine setters?

- Occupational Safety and Health Administration (OSHA) regulations

- National Electrical Code (NEC)

- Institute of Electrical and Electronics Engineers (IEEE) standards

- National Fire Protection Association (NFPA) codes

9. What are the quality control procedures that you follow when setting up and maintaining induction machines?

- Following manufacturer’s specifications

- Using calibrated tools and equipment

- Documenting all maintenance and repairs

- Regularly inspecting machines for any signs of wear or damage

- Testing machines to ensure they are operating within specified parameters

10. How do you stay up-to-date with the latest advancements in induction machine technology?

- Reading technical journals and articles

- Attending industry conferences and workshops

- Taking online courses and webinars

- Networking with other induction machine professionals

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Induction Machine Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Induction Machine Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Induction Machine Setter is responsible for the initial setup and operation of induction machines used in the manufacturing process. Key responsibilities of an Induction Machine Setter include the following:

1. Machine Setup and Adjustments

The Induction Machine Setter is responsible for setting up and adjusting the induction machine to meet specific production requirements. This involves:

- Installing and calibrating sensors and other machine components

- Adjusting machine settings, such as speed, temperature, and pressure

- Ensuring that the machine is operating within specified parameters

2. Process Monitoring and Control

Once the machine is set up, the Induction Machine Setter is responsible for monitoring and controlling the induction process. This involves:

- Observing the machine’s operation and identifying any potential problems

- Making adjustments to the machine settings as needed to maintain optimal operating conditions

- Ensuring that the induction process is producing the desired results

3. Troubleshooting and Maintenance

The Induction Machine Setter is also responsible for troubleshooting and maintaining the induction machine. This involves:

- Identifying and diagnosing machine problems

- Performing routine maintenance tasks, such as cleaning and lubricating the machine

- Making repairs to the machine as needed

4. Quality Control

The Induction Machine Setter is also responsible for ensuring the quality of the parts produced by the induction machine. This involves:

- Inspecting parts for defects

- Making adjustments to the machine settings as needed to improve part quality

- Maintaining records of production data to track part quality

Interview Tips

Preparing for an Induction Machine Setter interview can help you showcase your skills and experience and increase your chances of success. Here are some interview tips to help you ace the interview:

1. Research the Company and the Job

Before the interview, take some time to research the company and the specific job you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on their website, social media pages, and other online sources.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this job?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly. You can also prepare for questions specific to the Induction Machine Setter role, such as “What is your experience with induction machines?” and “How do you troubleshoot induction machine problems?”

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the Induction Machine Setter role. For example, you can discuss your experience with setting up, operating, and maintaining induction machines. You can also mention any specific training or certifications you have in induction machine operation.

4. Be Enthusiastic and Professional

It is important to be enthusiastic and professional throughout the interview. This will show the interviewer that you are interested in the job and that you are confident in your abilities. Be sure to make eye contact, speak clearly, and dress appropriately. You should also be prepared to ask questions about the job and the company. This will show the interviewer that you are engaged and interested in the opportunity.

5. Follow Up After the Interview

After the interview, be sure to follow up with the interviewer. This could involve sending a thank-you note or email, or calling the interviewer to reiterate your interest in the job. Following up shows the interviewer that you are still interested in the job and that you are serious about your application.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Induction Machine Setter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.