Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Plate Furnace Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Plate Furnace Operator so you can tailor your answers to impress potential employers.

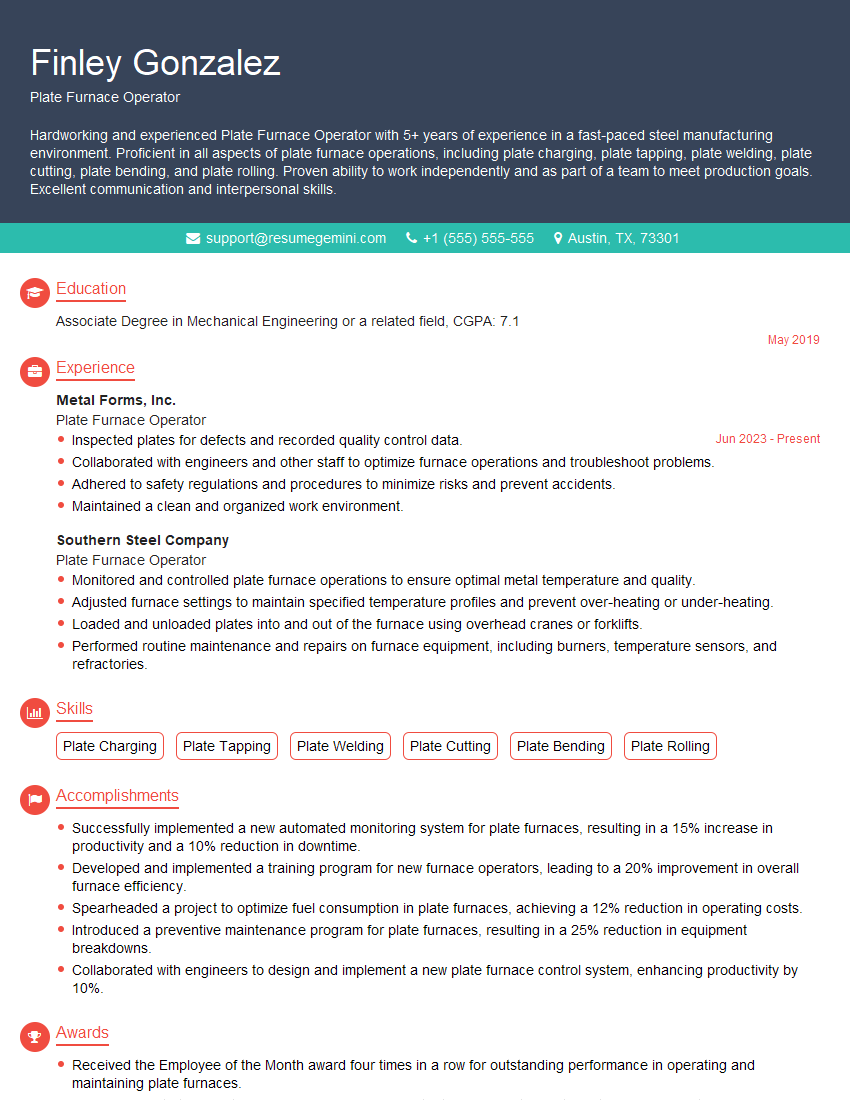

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plate Furnace Operator

1. Describe the process of operating a plate furnace?

The process of operating a plate furnace involves several key steps:

- Charging the furnace: Load the scrap metal into the furnace using a charging machine.

- Melting the scrap: Heat the scrap metal to its melting point using burners or electric arcs.

- Refining the molten metal: Remove impurities from the molten metal using fluxes and other refining agents.

- Casting the molten metal: Pour the molten metal into molds to create plates of the desired shape and thickness.

- Cooling and finishing: Allow the plates to cool and perform any necessary finishing operations, such as cutting, straightening, or surface treatment.

2. What are the different types of plate furnaces and their advantages and disadvantages?

Electric arc furnaces (EAFs):

- Advantages: Fast melting rate, flexible operation, and ability to refine metals using electric power.

- Disadvantages: High energy consumption, electrode consumption, and potential for noise and emissions.

Induction furnaces:

- Advantages: Non-contact melting, reduced electrode consumption, and improved metal quality.

- Disadvantages: Slower melting rate and higher capital cost.

Gas-fired furnaces:

- Advantages: Lower capital cost, use of readily available fuel, and potential for lower emissions.

- Disadvantages: Slower melting rate, higher fuel consumption, and need for proper combustion control.

3. What are the key parameters to monitor and control in a plate furnace operation?

Key parameters to monitor and control include:

- Temperature: Ensure the furnace is operating at the correct temperature for melting, refining, and casting.

- Atmosphere: Control the furnace atmosphere to prevent oxidation and impurities in the molten metal.

- Power consumption: Monitor the energy usage of the furnace to optimize efficiency.

- Scrap quality: Ensure the scrap metal meets specifications to avoid contamination and defects in the final product.

- Furnace lining: Monitor the condition of the furnace lining to prevent refractory damage and maintain optimal heat transfer.

4. Describe the safety procedures and protocols for working with a plate furnace?

Safety procedures include:

- Protective gear: Wear appropriate personal protective equipment (PPE) such as fire-resistant clothing, gloves, and eye protection.

- Machine guarding: Ensure all machinery is properly guarded to prevent contact with moving parts.

- Electrical safety: Follow electrical safety protocols to avoid shocks and electrical accidents.

- Fire prevention: Implement fire prevention measures such as proper storage of flammable materials and regular inspections.

- Emergency procedures: Be aware of emergency procedures in case of accidents or equipment malfunctions.

5. What is the role of fluxes in plate furnace operations?

Fluxes play a crucial role in refining molten metal by:

- Removing impurities: Reacting with impurities to form slag, which can be removed from the molten metal.

- Protecting the molten metal: Forming a protective layer on the surface to prevent oxidation.

- Adjusting the chemical composition: Adding or removing specific elements to achieve desired metal properties.

- Improving fluidity: Reducing the viscosity of the molten metal to enhance its flowability and casting characteristics.

6. Explain the importance of maintaining the furnace refractory lining?

Maintaining the refractory lining is crucial for:

- Insulation: Refractory lining acts as an insulator, minimizing heat loss and improving energy efficiency.

- Protection: It protects the furnace shell from high temperatures and corrosive molten metal.

- Longevity: A properly maintained refractory lining extends the lifespan of the furnace.

- Safety: Prevents refractory damage and potential leaks of molten metal or gases.

7. Describe the different casting techniques used in plate furnace operations?

Common casting techniques include:

- Continuous casting: Used to produce long, thin plates by continuously pouring molten metal into a mold.

- Semi-continuous casting: Similar to continuous casting, but involves intermittent stops to allow for solidification and cutting.

- Ingot casting: Pouring molten metal into molds to create ingots, which are then rolled into plates.

- Slab casting: Casting molten metal into large, thick slabs, which are then cut into plates.

8. What are the quality control measures implemented in plate furnace operations?

Quality control measures include:

- Raw material inspection: Verifying the quality and composition of scrap metal before charging.

- Molten metal analysis: Regularly sampling and analyzing the molten metal to monitor its composition and properties.

- Non-destructive testing: Using techniques such as ultrasonic testing or radiography to detect defects in the finished plates.

- Dimensional inspection: Verifying the dimensions, thickness, and surface quality of the plates.

- Mechanical testing: Conducting tests to assess the mechanical properties of the plates, such as tensile strength and hardness.

9. How do you troubleshoot common problems encountered in plate furnace operations?

Common problems include:

- Refractory failure: Identify the cause of the failure, such as excessive heat or improper maintenance, and implement corrective measures.

- Molten metal contamination: Analyze the molten metal to identify the source of contamination and adjust the refining process or scrap quality.

- Casting defects: Determine the type of defect (e.g., cracks, inclusions, voids) and identify the underlying cause, such as improper casting parameters or mold issues.

- Furnace downtime: Troubleshoot electrical, mechanical, or refractory problems to minimize downtime and restore furnace operation.

10. Discuss the future trends and advancements in plate furnace technology?

Emerging trends include:

- Energy efficiency: Focus on reducing energy consumption through improved insulation and process optimization.

- Automation: Implementation of automated systems for charging, melting, and casting operations.

- Environmental sustainability: Minimizing emissions and waste by optimizing furnace performance and adopting sustainable practices.

- Data analytics: Using sensors and data analysis to monitor and optimize furnace operations.

- Advanced materials: Development of new refractory materials with improved durability and performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plate Furnace Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plate Furnace Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plate Furnace Operators play a pivotal role in the production of steel by operating and controlling plate furnaces.

1. Furnace Operation and Control

The primary responsibility of a Plate Furnace Operator is to skillfully operate and control plate furnaces, ensuring optimal performance and product quality.

- Monitor and adjust furnace temperatures, gas flow, and pressure to maintain precise heating conditions.

- Inspect furnaces regularly for any signs of damage or malfunction and report any issues promptly.

2. Raw Material Handling

Plate Furnace Operators are responsible for handling and charging raw materials into the furnaces.

- Load steel slabs or rolls into the furnace using overhead cranes or other material handling equipment.

- Ensure proper placement and spacing of materials to optimize heating and minimize defects.

3. Product Quality Assurance

Maintaining the quality of steel products is a crucial aspect of their role.

- Monitor and inspect heated materials during the heating process to identify any irregularities or defects.

- Take samples of steel for quality control testing and verify the adherence to specifications.

4. Process Monitoring and Documentation

Plate Furnace Operators are responsible for monitoring and documenting the furnace operation and production processes.

- Record and maintain accurate logs of furnace operating parameters, including temperatures, pressures, and gas flow rates.

- Monitor and record production data, such as throughput, yield, and scrap rates.

Interview Tips

Preparing well for a Plate Furnace Operator interview can significantly improve your chances of success.

1. Research the Company and Position

Take the time to thoroughly research the company and the specific role you’re applying for. This will help you understand their business, goals, and the responsibilities of the position.

- Visit the company’s website and read about their products, services, and history.

- Review the job description carefully and identify the key skills and experience required.

2. Tailor Your Resume and Cover Letter

Highlight your skills and experience that are most relevant to the job requirements. Use specific examples and quantify your accomplishments whenever possible.

- Use keywords from the job description in your resume and cover letter.

- Showcase your experience in operating and controlling plate furnaces or similar industrial equipment.

3. Practice Common Interview Questions

Practice answering common interview questions that you’re likely to encounter, such as:

- Tell me about your experience in operating plate furnaces.

- How do you ensure the quality of steel products during the heating process?

- Describe your approach to process monitoring and documentation.

4. Prepare Questions for the Interviewer

Asking well-thought-out questions at the end of the interview demonstrates your interest in the position and the company. Some good questions to consider include:

- What are the company’s goals for the plate furnace operation?

- Can you describe the safety protocols and procedures in place for plate furnace operators?

- What opportunities are there for professional development and career growth within the organization?

Next Step:

Now that you’re armed with the knowledge of Plate Furnace Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Plate Furnace Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini