Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tool Hardener position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

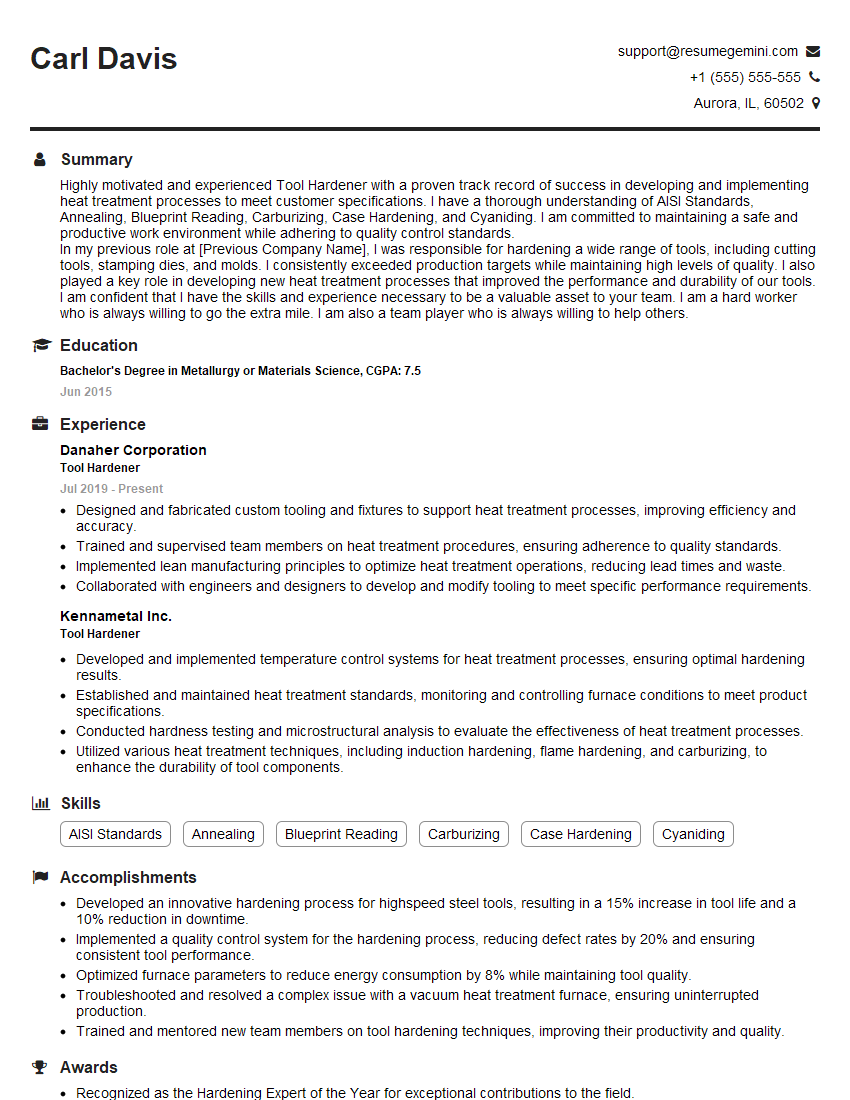

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool Hardener

1. What are the different types of heat treatment processes used in tool hardening?

- Annealing

- Normalizing

- Quenching and tempering

- Carburizing

- Nitriding

2. Explain the process of quenching and tempering.

Quenching

- Heating steel to a temperature above its critical temperature

- Rapidly cooling the steel by immersing it in water, oil, or salt

Tempering

- Reheating the quenched steel to a temperature below its critical temperature

- Cooling the steel slowly

3. What are the benefits of heat treating tools?

- Increased hardness and wear resistance

- Improved strength and toughness

- Reduced distortion and cracking

- Enhanced corrosion resistance

4. What are the different types of tool steels?

- Carbon tool steels

- Alloy tool steels

- High-speed tool steels

- Stainless tool steels

5. How do you select the right tool steel for a particular application?

- Consider the type of material being processed

- Determine the desired hardness and wear resistance

- Select a tool steel with the appropriate alloying elements

- Consider the heat treatment process that will be used

6. What are the common defects that can occur during tool hardening?

- Cracking

- Distortion

- Soft spots

- Hard spots

- Decarburization

7. How do you prevent defects from occurring during tool hardening?

- Use the correct heat treatment process

- Control the temperature and quench rate

- Use preheat and postheat treatments

- Protect the steel from oxidation and decarburization

8. What are the different methods for testing the hardness of tools?

- Rockwell hardness test

- Vickers hardness test

- Brinell hardness test

- Knoop hardness test

9. What are the different methods for testing the wear resistance of tools?

- Abrasive wear test

- Adhesive wear test

- Fretting wear test

- Erosion wear test

10. What are the latest trends in tool hardening technology?

- Laser heat treatment

- Induction heat treatment

- Vacuum heat treatment

- Plasma heat treatment

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool Hardener.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool Hardener‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool Hardeners are highly-skilled professionals responsible for the treatment of metals, primarily using heat treatment techniques, to enhance their hardness, durability, and resistance to wear and tear. They are employed in various industrial settings, such as manufacturing plants and metalworking facilities. The key job responsibilities of a Tool Hardener include:

1. Heat Treating and Tempering Metals

Tool Hardeners utilize heat treatment processes, including annealing, quenching, and tempering, to modify the properties of metals. They control temperature, heating time, and cooling rates to achieve the desired hardness and strength levels.

2. Operating and Maintaining Heat Treating Equipment

Tool Hardeners operate and maintain a range of heat treating equipment, such as furnaces, ovens, and quenching tanks. They ensure the proper functioning of these machines to achieve precise temperature control and uniform heating.

3. Testing and Inspecting Treated Metals

Tool Hardeners conduct various tests, including hardness testing, tensile testing, and metallographic examination, to assess the quality and performance of treated metals. They evaluate the results to ensure compliance with specifications and identify any areas for improvement.

4. Monitoring Production Processes

Tool Hardeners monitor production processes to optimize heat treatment operations. They track temperature profiles, record data, and identify potential issues to improve efficiency and maintain quality standards.

5. Maintaining a Safe and Clean Work Environment

Tool Hardeners prioritize safety by adhering to established safety protocols and maintaining a clean and organized work environment. They properly handle hazardous materials, wear appropriate protective gear, and follow environmental regulations.

Interview Preparation Tips

To effectively prepare for an interview for a Tool Hardener position, it is crucial to:

1. Research the Company and Industry

Familiarize yourself with the company’s background, products or services, and industry trends. This knowledge will enable you to demonstrate your interest in the company and show that you have a good understanding of the field.

2. Practice Your Answers to Common Interview Questions

Anticipate and prepare answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?” Tailor your responses to highlight your relevant skills and experiences.

3. Highlight Your Technical Expertise

Emphasize your technical knowledge and experience in heat treatment processes, metallurgy, and testing methods. Provide specific examples of successful projects or challenges you have encountered in your previous roles.

4. Showcase Your Problem-Solving Abilities

Tool Hardeners are often required to troubleshoot issues and find solutions. Highlight your ability to analyze problems, develop innovative solutions, and work effectively under pressure.

5. Emphasize Safety and Quality Control

Stress your commitment to safety and quality control. Share examples of how you have implemented safety measures and maintained high standards in your previous roles.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Tool Hardener role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.