Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tempering Oven Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

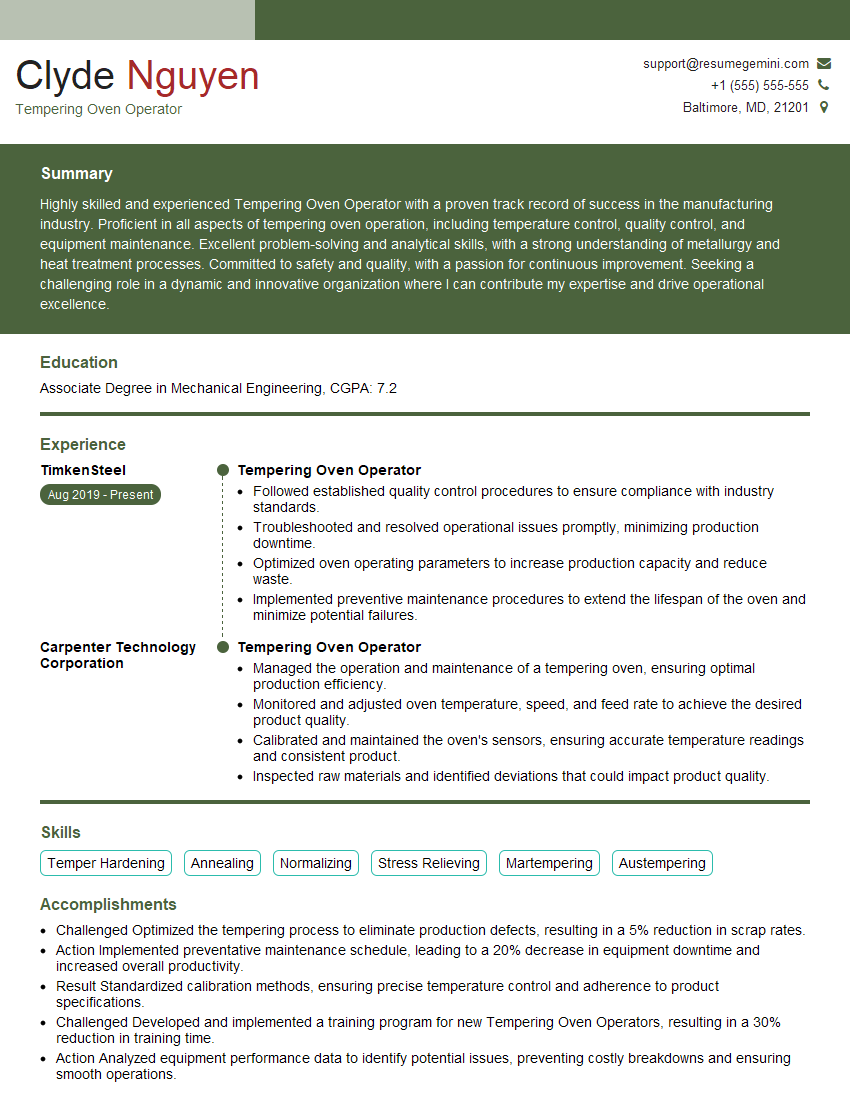

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tempering Oven Operator

1. Describe the key responsibilities of a Tempering Oven Operator?

- Operate and monitor tempering ovens to achieve desired hardness and microstructure of metal components.

- Control oven temperature, heating and cooling rates, and holding times according to specifications.

2. Explain the different types of tempering processes and their applications?

- Reduces internal stresses in metal components.

- Improves toughness and ductility by softening the metal.

- Increases hardness and wear resistance while maintaining some ductility.

: Stress Relief Tempering

Subheading: Annealing Tempering

Subheading: Tempering for Hardness

3. How do you calibrate and maintain a tempering oven?

- Use calibrated thermocouples and temperature recorders to verify accuracy.

- Inspect and clean heating elements, fans, and other components regularly.

4. What safety precautions are important when operating a tempering oven?

- Wear appropriate protective gear, including gloves and safety glasses.

- Handle hot components with care using tongs or gloves.

5. How do you troubleshoot common problems with tempering ovens?

- Check heating elements, thermocouples, and electrical connections.

- Inspect for any leaks or blockages in the oven chamber.

6. Describe the importance of quality control in tempering operations?

- Ensures that components meet specified hardness and microstructure requirements.

- Prevents defects that could impact product reliability and safety.

7. How do you stay updated with advances in tempering technology and best practices?

- Attend industry conferences and workshops.

- Read technical publications and consult with experts.

8. What are the key performance indicators for a Tempering Oven Operator?

- Oven uptime and efficiency.

- Product quality and consistency.

- Safety compliance.

9. How do you prioritize tasks and manage multiple ovens?

- Establish work priorities based on production schedules and deadlines.

- Monitor multiple ovens simultaneously and adjust parameters as needed.

10. What qualities and skills are essential for a successful Tempering Oven Operator?

- Strong technical knowledge of tempering processes.

- Attention to detail and quality consciousness.

- Ability to work independently and as part of a team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tempering Oven Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tempering Oven Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tempering Oven Operator plays a crucial role in ensuring the quality and safety of tempered glass products within the manufacturing industry. Their primary responsibilities revolve around operating and maintaining tempering ovens, adhering to safety protocols, and monitoring the tempering process to achieve desired glass specifications.

1. Oven Operation and Maintenance

Operate tempering ovens efficiently, ensuring smooth production flow.

Conduct regular maintenance checks, including cleaning, lubricating, and inspecting equipment for potential issues.

2. Production Monitoring and Quality Control

Monitor the tempering process closely, adjusting settings such as temperature, time, and pressure to achieve desired glass properties.

Inspect tempered glass products for defects, ensuring they meet quality standards and customer specifications.

3. Safety Compliance and Protocol Adherence

Strictly adhere to established safety protocols and procedures to minimize risks and maintain a safe work environment.

Wear appropriate personal protective equipment (PPE) and follow all safety guidelines.

4. Process Optimization and Troubleshooting

Identify areas for process improvement and implement measures to enhance efficiency and productivity.

Troubleshoot and resolve technical issues with tempering ovens and related equipment.

Interview Tips

To prepare effectively for a Tempering Oven Operator interview, it is essential to familiarize yourself with the key responsibilities and industry-specific knowledge. Here are some tips to help you ace your interview:

1. Research the Company and Industry

Thoroughly research the company you are applying to and the glass manufacturing industry as a whole.

Understand their products, processes, and market position to demonstrate your interest and knowledge.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience in operating tempering ovens, monitoring production, and ensuring quality control.

Provide specific examples of your work history that showcase your abilities and how they align with the job requirements.

3. Prepare for Technical Questions

Be prepared to answer technical questions related to tempering ovens, their operation, and troubleshooting techniques.

Review the principles of glass tempering, different types of tempering ovens, and common safety protocols.

4. Practice Common Interview Questions

Practice answering common interview questions, such as “Why are you interested in this role?” and “What are your strengths and weaknesses?”.

Prepare thoughtful responses that highlight your qualifications and enthusiasm for the position.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tempering Oven Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tempering Oven Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.