Are you gearing up for an interview for a Anodizing Line Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Anodizing Line Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

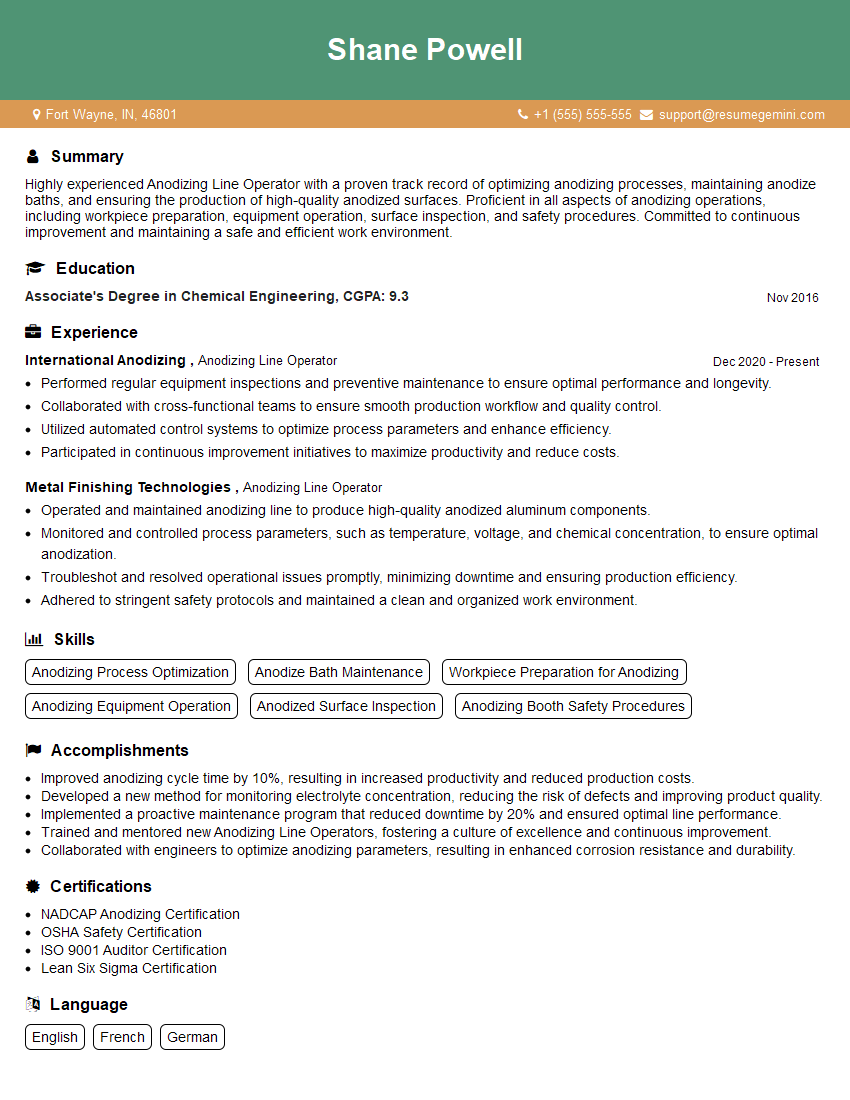

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Anodizing Line Operator

1. Describe the steps involved in the anodizing process.

The anodizing process involves several steps to create a protective and decorative oxide layer on the surface of metal, typically aluminum. The steps include:

- Cleaning: The metal surface is cleaned to remove any dirt, grease, or other contaminants.

- Deoxidizing: Any existing oxide layer is removed using a chemical solution.

- Anodizing: The metal is immersed in an electrolytic solution and subjected to an electric current, causing anodic oxidation to form a porous oxide layer on the surface.

- Sealing: The oxide layer is sealed by boiling the metal in water or using a chemical sealant, enhancing its corrosion resistance and durability.

- Dyeing (optional): Dyes can be introduced into the oxide layer to create a variety of colors.

2. Explain the purpose of sulfuric acid in the anodizing process.

Electrolytic Solution

- Sulfuric acid is the most common electrolyte used in anodizing, providing a stable and efficient environment for the formation of the oxide layer.

- It helps control the thickness, porosity, and hardness of the oxide layer by adjusting its concentration and operating parameters.

Surface Activation

- Sulfuric acid plays a crucial role in activating the metal surface before anodizing, removing any passive oxide layers or contaminants.

- This activation enhances the adhesion and uniformity of the oxide layer.

3. How do you determine the thickness of the anodized layer?

- Microscopic Measurement: Using a scanning electron microscope (SEM) or optical microscope with cross-sectioning, the thickness can be measured directly on the anodized surface.

- Coating Thickness Gauge: A non-destructive method that utilizes an eddy current or magnetic induction gauge to measure the thickness without damaging the coating.

- Gravimetric Analysis: Weighing the sample before and after anodizing and calculating the weight difference, which is proportional to the oxide layer thickness.

- Standard Test Methods: Following industry standards such as ASTM B658 or ISO 3210, which provide standardized procedures for thickness measurement.

4. Describe the types of defects that can occur during the anodizing process and how to prevent them.

Defects

- Burning: Excessive current density or prolonged anodizing can cause localized overheating and burning of the metal.

- Scratches: Improper handling or cleaning can result in scratches or other mechanical damage to the anodized surface.

- Uneven Coating: Inconsistencies in the anodizing process, such as uneven current distribution or contamination, can lead to uneven oxide layer thickness.

- Sealing Issues: Incomplete or inadequate sealing can compromise the corrosion resistance and durability of the anodized layer.

Prevention

- Optimize operating parameters (current density, voltage, temperature).

- Ensure proper cleaning and handling of parts.

- Monitor and control the anodizing process consistently.

- Use high-quality sealing solutions and follow proper sealing procedures.

5. How do you maintain the anodizing line for optimal performance?

- Regular Cleaning: Clean the tanks, fixtures, and equipment to prevent contamination and buildup.

- Solution Monitoring: Regularly check the electrolyte concentration, pH, and temperature to ensure they are within specifications.

- Equipment Maintenance: Inspect and maintain electrical components, pumps, and other equipment for proper operation.

- Calibration and Documentation: Calibrate instruments and document operating parameters to maintain consistency and traceability.

- Process Optimization: Continuously monitor and adjust the process based on performance data to achieve optimal results.

6. Discuss the safety precautions to be taken when working on an anodizing line.

- Chemical Handling: Wear appropriate protective gear (gloves, goggles, apron) when handling acids and chemicals.

- Electrical Hazards: Be aware of high voltage and follow electrical safety protocols.

- Hot Surfaces: Be cautious of heated tanks and components.

- Ventilation: Ensure adequate ventilation to remove fumes and gases generated during the process.

- Emergency Procedures: Familiarize yourself with emergency procedures and know the location of safety equipment.

7. How do you calculate the anodizing time based on the desired oxide layer thickness?

- Determine the growth rate of the oxide layer for the specific alloy and anodizing conditions (typically given in micrometers per volt-hour).

- Calculate the required oxide layer thickness based on the desired specifications.

- Formula: Anodizing Time = (Oxide Thickness / Growth Rate) * Voltage

- Adjust the anodizing voltage and time accordingly to achieve the target thickness.

- Monitor the oxide layer thickness during the process to ensure accuracy.

8. Explain the role of agitation in the anodizing process.

- Uniform Coating: Agitation helps maintain a uniform distribution of ions in the electrolyte solution, ensuring consistent oxide layer growth on all surfaces.

- Heat Dissipation: Agitation promotes heat transfer, preventing localized overheating and potential burning of the metal.

- Byproduct Removal: It aids in the removal of gas bubbles and byproducts generated during the anodizing process, improving the quality of the oxide layer.

9. Describe the different types of dyes used in the anodizing process and their properties.

- Acid Dyes: Water-soluble dyes that are absorbed into the anodized oxide layer, providing a wide range of colors.

- Metal Complex Dyes: Form a strong bond with the metal oxide, resulting in vibrant and durable colors with excellent lightfastness.

- Electrolytic Dyes: Introduced into the anodizing solution during the process, creating a permanent and integral part of the oxide layer.

- Organic Dyes: Solvent-based dyes that are applied to the anodized surface after sealing, offering flexibility in color selection.

10. Explain the advantages and disadvantages of using anodized aluminum.

Advantages

- Corrosion Resistance: The oxide layer provides excellent protection against corrosion, enhancing the durability of aluminum.

- Durability: Anodized aluminum is resistant to wear, abrasion, and fading, extending its lifespan.

- Decorative Appeal: Anodizing offers a wide range of colors and finishes, allowing for customization and aesthetic enhancement.

- Electrical Insulation: The oxide layer acts as an electrical insulator, making anodized aluminum suitable for electrical applications.

Disadvantages

- Cost: Anodizing can be more expensive than other coating methods.

- Size Limitations: The size of parts that can be anodized is limited by the size of the anodizing tank.

- Limited Formability: Anodized aluminum may have reduced formability compared to unanodized aluminum.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Anodizing Line Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Anodizing Line Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Anodizing Line Operators are responsible for the smooth and efficient operation of anodizing lines.

1. Monitor and Control Anodizing Process

Monitor and control all aspects of the anodizing process, including:

- Temperature

- Voltage

- Current

- Chemical concentration

2. Load and Unload Parts

Load and unload parts from the anodizing line.

- Ensure that parts are properly racked and secured.

- Inspect parts for defects before loading them onto the line.

3. Perform Quality Control Checks

Perform quality control checks on finished parts to ensure that they meet specifications.

- Measure the thickness of the anodized coating.

- Inspect the coating for defects such as pitting or scratching.

4. Maintain Anodizing Equipment

Maintain the anodizing equipment to ensure that it is operating properly.

- Inspect the equipment for signs of wear or damage.

- Clean and lubricate the equipment.

Interview Tips

Preparing for an interview for an Anodizing Line Operator position can be a daunting task, but by following these tips, you can increase your chances of success.

1. Research the Company and the Position

Take some time to learn about the company you are applying to and the specific job opening.

- Visit the company’s website to learn about their products, services, and culture.

- Read the job description carefully to understand the responsibilities and qualifications required for the position.

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you are likely to be asked, such as:

- Tell me about your experience in the anodizing industry.

- What are your strengths and weaknesses as an anodizing line operator?

- Why are you interested in this position?

3. Be Prepared to Talk About Your Technical Skills

The interviewer will want to know about your technical skills and experience as an anodizing line operator.

- Be prepared to discuss your experience with different types of anodizing equipment.

- Describe your knowledge of the anodizing process.

4. Be Enthusiastic and Positive

The interviewer will be looking for someone who is enthusiastic about the anodizing industry and eager to learn and grow.

- Be positive and upbeat during the interview.

- Show your enthusiasm for the position and the company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Anodizing Line Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.