Are you gearing up for an interview for a Bronze Plater position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Bronze Plater and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

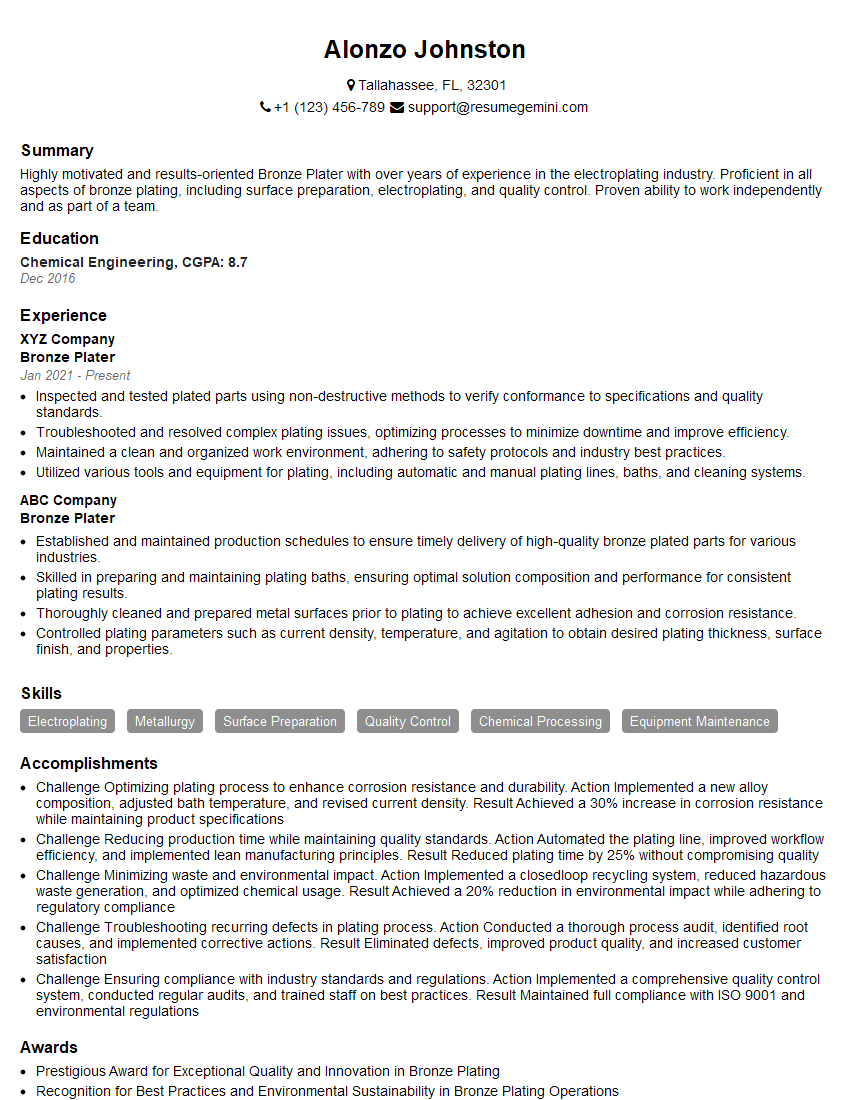

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bronze Plater

1. Can you describe the process of bronze plating?

The process of bronze plating involves several steps. Here is a detailed overview:

- Surface preparation: The first step is to prepare the surface of the object to be plated by cleaning it thoroughly to remove any contaminants or oils that could interfere with the plating process. This can be done by using a degreaser, followed by an acid etch to remove any remaining oxides.

- Activation: The next step is to activate the surface of the object by immersing it in an acid solution, such as hydrochloric acid or sulfuric acid, which helps to create a surface that is more receptive to the plating solution.

- Plating: The object is then immersed in a bronze plating solution, which typically consists of a mixture of copper sulfate, tin sulfate, and sodium cyanide. An electric current is passed through the solution, which causes the bronze ions to deposit onto the surface of the object.

- Rinsing: After plating, the object is rinsed thoroughly to remove any residual plating solution.

- Drying: The object is then dried to prevent it from oxidizing.

2. What are the different types of bronze plating solutions and their applications?

Acidic bronze plating solution

- Applications: Used for general-purpose plating, provides a bright and durable finish

Alkaline bronze plating solution

- Applications: Produces a softer and more corrosion-resistant finish, suitable for decorative purposes

Cyanide bronze plating solution

- Applications: Produces a high-quality, bright finish, commonly used in jewelry and decorative applications

3. How do you control the thickness of the bronze plating?

The thickness of the bronze plating can be controlled by several factors:

- Plating time: The longer the object is immersed in the plating solution, the thicker the plating will be.

- Current density: The higher the current density, the thicker the plating will be.

- Temperature: The higher the temperature of the plating solution, the thicker the plating will be.

4. What are the common defects in bronze plating and how can they be prevented?

Some common defects in bronze plating include:

- Blisters: These are caused by trapped air or hydrogen gas in the plating, and can be prevented by proper cleaning and activation of the surface before plating.

- Cracks: These are caused by internal stresses in the plating, and can be prevented by using a plating solution with the correct composition and temperature.

- Peeling: This is caused by poor adhesion between the plating and the base metal, and can be prevented by proper surface preparation and activation.

5. What are the safety precautions that need to be taken when bronze plating?

Bronze plating involves the use of chemicals that can be hazardous, so it is important to take the following safety precautions:

- Wear appropriate personal protective equipment, such as gloves, eye protection, and a respirator.

- Work in a well-ventilated area to avoid inhaling fumes.

- Dispose of chemicals properly according to local regulations.

6. How do you measure the thickness of a bronze plating?

The thickness of a bronze plating can be measured using a variety of methods, including:

- Micrometer: A micrometer can be used to measure the thickness of a plating by measuring the difference in thickness between the plated and unplated areas.

- X-ray fluorescence (XRF): XRF is a non-destructive method that uses X-rays to measure the elemental composition of a material, including the thickness of a plating.

- Electromagnetic induction: Electromagnetic induction is a non-destructive method that uses electromagnetic fields to measure the thickness of a plating.

7. What are the advantages and disadvantages of bronze plating?

Advantages:

- Improved corrosion resistance

- Enhanced wear resistance

- Good electrical conductivity

- Decorative appearance

Disadvantages:

- Can be more expensive than other plating methods

- Requires specialized equipment and chemicals

- Can be harmful to the environment if not disposed of properly

8. What is the difference between bronze plating and brass plating?

Bronze plating and brass plating are both copper-based plating processes, but they differ in the composition of the plating solution. Bronze plating uses a solution that contains copper and tin, while brass plating uses a solution that contains copper and zinc.

Bronze plating produces a harder and more corrosion-resistant finish than brass plating, but it is also more expensive. Brass plating produces a more decorative finish and is less expensive than bronze plating.

9. What are some of the applications of bronze plating?

Bronze plating is used in a variety of applications, including:

- Automotive parts

- Marine hardware

- Electrical components

- Jewelry

- Decorative items

10. What is the future of bronze plating?

Bronze plating is a well-established technology that is expected to continue to be used in a variety of applications in the future. However, there are some emerging technologies that could potentially replace bronze plating in some applications.

One promising technology is electroless plating, which does not require the use of an electric current. Electroless plating is still in its early stages of development, but it has the potential to be a more cost-effective and environmentally friendly alternative to bronze plating.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bronze Plater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bronze Plater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Bronze Plater, you will have the fundamental responsibility of applying a thin layer of bronze to metal surfaces through an electrolytic process. This involves preparing the surfaces, operating electrolytic cells, and ensuring the quality of the finished products. Your key job responsibilities include:

1. Surface Preparation

Thoroughly clean and prepare metal surfaces by degreasing, pickling, and activating them to ensure proper adhesion of the bronze coating.

2. Electrolytic Plating

Immerse the prepared surfaces in an electrolytic bath containing a bronze solution. Monitor and adjust the electrical current, temperature, and solution composition to achieve the desired coating thickness, color, and adhesion.

3. Quality Control

Inspect and test the plated surfaces to ensure they meet specified standards for thickness, adhesion, and appearance. Identify and rectify any defects or non-conformities.

4. Equipment Maintenance

Maintain and calibrate plating equipment, including electrolytic cells, rectifiers, and filtration systems. Troubleshoot and resolve any technical issues to ensure optimal performance.

Interview Tips

To ace your interview for a Bronze Plater position, here are some preparation tips:

1. Research the Company and Position

Thoroughly research the company, its products, and the specific role you are applying for. This will demonstrate your interest and enthusiasm for the opportunity.

2. Highlight Relevant Experience

Emphasize your experience in surface preparation, electrolytic plating, and quality control. Quantify your accomplishments whenever possible, using specific examples and metrics.

3. Showcase Technical Knowledge

Be prepared to discuss the principles of electrolytic plating, including the factors that affect coating thickness, adhesion, and appearance. Show your understanding of the equipment and processes involved.

4. Prepare for Common Interview Questions

Practice answering common interview questions, such as “Why are you interested in this role?” and “What are your strengths and weaknesses as a Bronze Plater?”

5. Be Enthusiastic and Professional

Demonstrate your passion for the industry and your commitment to delivering high-quality work. Maintain a positive attitude and be respectful throughout the interview.

6. Ask Thoughtful Questions

At the end of the interview, ask insightful questions that show your interest in the company and the position. This will leave a lasting impression on the interviewers.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Bronze Plater role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.