Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Corrosion Prevention Metal Sprayer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Corrosion Prevention Metal Sprayer so you can tailor your answers to impress potential employers.

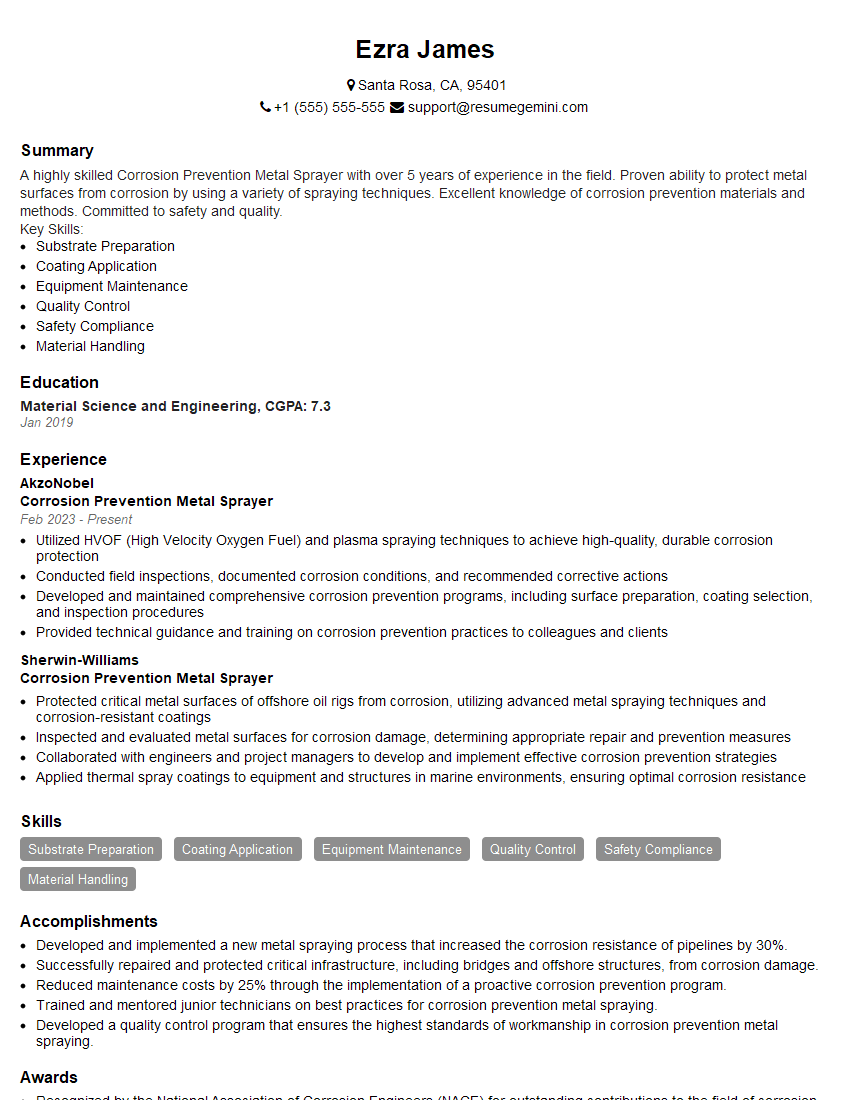

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Corrosion Prevention Metal Sprayer

1. Describe the different types of corrosion prevention metal spraying techniques?

There are several types of corrosion prevention metal spraying techniques, including:

- Arc spraying: This process involves melting metal wire with an electric arc and spraying the molten metal onto the surface to be protected.

- Flame spraying: This process involves melting metal wire or powder with a flame and spraying the molten material onto the surface to be protected.

- Plasma spraying: This process involves melting metal powder with a plasma torch and spraying the molten material onto the surface to be protected.

- HVOF spraying: This process involves heating a mixture of metal powder and fuel gas to a high velocity and spraying the resulting mixture onto the surface to be protected.

2. What are the factors that affect the quality of a metal sprayed coating?

Surface preparation

- The surface to be coated must be clean, free of rust, and other contaminants.

- The surface must also be properly roughened to ensure good adhesion of the coating.

Spray parameters

- The spray parameters, such as the spray distance, spray angle, and powder feed rate, must be carefully controlled to ensure a uniform and high-quality coating.

Coating thickness

- The coating thickness must be sufficient to provide the desired level of corrosion protection.

- However, the coating thickness must not be too thick, as this can lead to cracking and other problems.

Post-treatment

- The metal sprayed coating may require post-treatment, such as heat treatment or sealing, to improve its corrosion resistance and durability.

3. What are the advantages and disadvantages of metal spraying?

Advantages

- Metal spraying can provide excellent corrosion protection for a wide range of metals.

- Metal spraying can be used to apply a wide range of coating materials, including metals, ceramics, and polymers.

- Metal spraying can be used to coat complex shapes and large surfaces.

- Metal spraying is a relatively low-cost process.

Disadvantages

- Metal spraying can be a slow process, especially for large surfaces.

- Metal spraying can generate fumes and dust, which can be a health hazard.

- Metal sprayed coatings can be susceptible to cracking and other problems if they are not properly applied and maintained.

4. What are the different types of metal spray guns?

- Arc spray guns: Arc spray guns use an electric arc to melt metal wire and spray the molten metal onto the surface to be protected.

- Flame spray guns: Flame spray guns use a flame to melt metal wire or powder and spray the molten material onto the surface to be protected.

- Plasma spray guns: Plasma spray guns use a plasma torch to melt metal powder and spray the molten material onto the surface to be protected.

- HVOF spray guns: HVOF spray guns use a high-velocity mixture of metal powder and fuel gas to spray the molten material onto the surface to be protected.

5. What are the safety precautions that must be taken when metal spraying?

- Wear appropriate personal protective equipment, such as a respirator, gloves, and eye protection.

- Ensure that the work area is well-ventilated.

- Do not spray near flammable materials.

- Follow the manufacturer’s instructions for the safe operation of the metal spray gun.

6. What are the different types of metal spray coatings?

- Metallic coatings: Metallic coatings are made from metals such as aluminum, zinc, and nickel.

- Ceramic coatings: Ceramic coatings are made from materials such as alumina, zirconia, and titanium dioxide.

- Polymer coatings: Polymer coatings are made from materials such as epoxy, polyurethane, and nylon.

7. What are the applications of metal spraying?

- Corrosion protection of metals

- Wear resistance

- Electrical insulation

- Thermal insulation

- Repair of damaged metal surfaces

8. What are the different factors that affect the cost of metal spraying?

- The type of metal spray coating: Some metal spray coatings are more expensive than others.

- The size of the surface to be coated: Larger surfaces require more material and labor, which can increase the cost.

- The complexity of the surface to be coated: Complex shapes can be more difficult to coat, which can increase the cost.

- The location of the work: Metal spraying can be more expensive in some locations than others.

9. What is the future of metal spraying?

- Metal spraying is a growing industry, as more and more businesses realize the benefits of this technology.

- New developments in metal spraying technology are making it possible to apply coatings that are more durable, corrosion-resistant, and wear-resistant than ever before.

- Metal spraying is expected to continue to be a valuable tool for businesses in a wide range of industries.

10. How do you stay up-to-date on the latest trends in metal spraying technology?

- Read industry publications and attend trade shows.

- Network with other metal sprayers and coating professionals.

- Take continuing education courses.

- Experiment with new materials and techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Corrosion Prevention Metal Sprayer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Corrosion Prevention Metal Sprayer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Corrosion Prevention Metal Sprayers are responsible for applying protective coatings to metal surfaces to prevent corrosion. They use a variety of techniques to apply these coatings, including thermal spraying, cold spraying, and plasma spraying.

1. Prepare Surfaces for Coating

Before applying a coating, the metal surface must be prepared to ensure a good bond. This may involve cleaning the surface, removing rust or other contaminants, and roughening the surface to increase adhesion.

2. Apply Coating

Once the surface is prepared, the coating is applied using a spray gun. The type of coating used will depend on the specific application. Some common coatings include zinc, aluminum, and ceramic.

3. Inspect Coatings

Once the coating has been applied, it is inspected to ensure that it is properly applied and free of defects. This may involve visual inspection, as well as nondestructive testing.

4. Maintain Equipment

Corrosion Prevention Metal Sprayers must also maintain their equipment to ensure that it is in good working order. This may involve cleaning the equipment, replacing worn parts, and performing regular maintenance checks.

Interview Tips

In order to ace an interview for a Corrosion Prevention Metal Sprayer position, it is important to be prepared and knowledgeable about the job. Here are some tips that can help you prepare for your interview:

1. Research the Company and Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific responsibilities of the position.

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and succinctly.

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience as a Corrosion Prevention Metal Sprayer. Be prepared to talk about your skills and experience in preparing surfaces for coating, applying coatings, inspecting coatings, and maintaining equipment.

4. Be Enthusiastic and Professional

It is important to be enthusiastic and professional during your interview. Show the interviewer that you are interested in the position and that you are confident in your abilities. Be polite and respectful, and dress professionally.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Corrosion Prevention Metal Sprayer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.