Feeling lost in a sea of interview questions? Landed that dream interview for Coating Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Coating Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

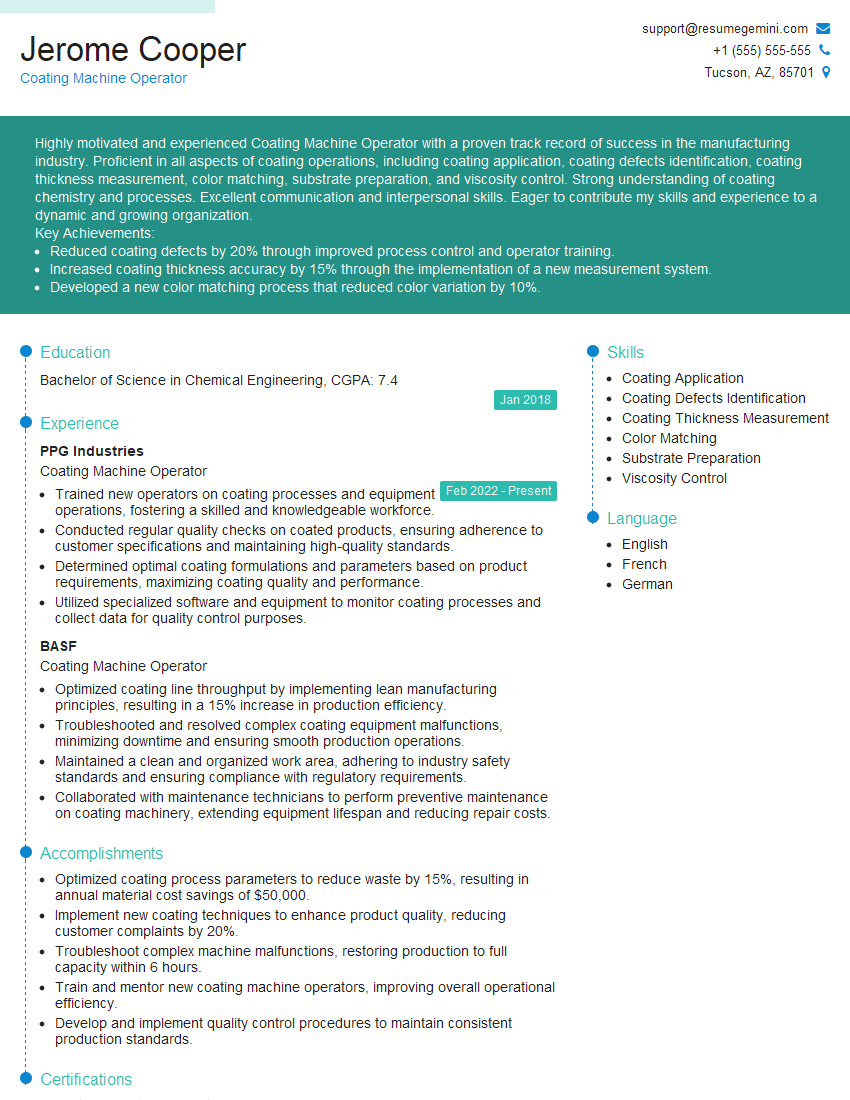

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coating Machine Operator

1. Explain the process of coating a substrate using a coating machine?

The process of coating a substrate using a coating machine involves several steps:

- Substrate Preparation: The substrate is first cleaned and prepared to ensure proper adhesion of the coating.

- Coating Application: The coating material is applied to the substrate using the appropriate coating method (e.g., spray coating, dip coating, or roller coating).

- Drying and Curing: The coated substrate is then dried and cured to solidify the coating and enhance its properties.

- Inspection and Quality Control: The coated surface is inspected for defects, thickness, and other quality parameters to ensure compliance with specifications.

2. What are the different types of coating machines?

Types of Coating Machines:

- Spray Coating Machine: Uses nozzles to atomize and spray the coating onto the substrate.

- Dip Coating Machine: Submerges the substrate in a bath of coating material.

- Roller Coating Machine: Applies the coating using rollers that transfer the material to the substrate.

- Electrostatic Coating Machine: Charges the coating particles to improve adhesion and reduce waste.

- Powder Coating Machine: Applies dry powder particles that are then melted and cured to form a coating.

3. How do you determine the appropriate coating thickness for a given application?

To determine the appropriate coating thickness, I consider several factors:

- Substrate Properties: The porosity, surface roughness, and material of the substrate affect the required coating thickness.

- Coating Material: The viscosity, solids content, and desired appearance of the coating influence its thickness.

- Application Method: The coating method used (e.g., spray or dip coating) affects the achievable thickness.

- Functional Requirements: The coating’s purpose (e.g., corrosion protection, electrical insulation) determines its required thickness.

4. What troubleshooting steps would you take if the coating is not adhering properly?

In case of poor coating adhesion, I would follow these troubleshooting steps:

- Substrate Inspection: Check the substrate for cleanliness, defects, or contamination that may hinder adhesion.

- Coating Material Verification: Ensure that the coating material is compatible with the substrate and has not degraded.

- Coating Preparation: Verify the proper mixing and application of the coating, including the correct viscosity and temperature.

- Surface Preparation Optimization: Adjust the substrate preparation methods to improve surface roughness and promote adhesion.

- Coating Curing Conditions: Check if the curing process is adequate and adjust temperature, time, or other parameters as needed.

5. How do you maintain and calibrate a coating machine?

Regular maintenance and calibration are crucial for optimal coating machine performance:

- Regular Cleaning: Clean nozzles, rollers, and other machine components to prevent clogs and ensure consistent coating application.

- Calibration: Use precision instruments to calibrate coating thickness gauges, temperature controllers, and other sensors to ensure accurate measurements and control.

- Preventive Maintenance: Schedule regular inspections and maintenance tasks to identify and address potential issues before they cause downtime.

- Lubrication: Lubricate moving parts to minimize friction and wear, ensuring smooth operation.

- Record Keeping: Maintain records of all maintenance and calibration activities for traceability and compliance.

6. What safety precautions should be taken when operating a coating machine?

To ensure safety while operating a coating machine, I adhere to the following precautions:

- Personal Protective Equipment (PPE): Wear gloves, safety glasses, and a respirator when handling chemicals and coatings.

- Proper Ventilation: Ensure adequate ventilation in the work area to prevent exposure to fumes or vapors.

- Electrical Safety: Inspect electrical connections regularly and follow lockout/tagout procedures during maintenance.

- Material Handling: Handle and store chemicals and coatings safely, following proper disposal procedures.

- Emergency Preparedness: Familiarize myself with emergency response plans and know the location of safety equipment.

7. What are the common defects that can occur during the coating process and their causes?

Common Coating Defects and Causes:

- Blisters: Entrapment of air or moisture under the coating, often due to poor surface preparation or curing conditions.

- Cracking: Excessive stress on the coating, caused by factors such as shrinkage, thermal expansion, or mechanical damage.

- Pinholing: Small holes in the coating, resulting from trapped air or contaminants in the material or substrate.

- Orange Peel: A rough, textured surface, caused by rapid evaporation of solvents during application.

- Fisheyes: Small, round defects that form due to contamination of the coating with oils or grease.

8. How do you ensure the quality of coated products?

To ensure the quality of coated products, I follow a comprehensive quality control process:

- Incoming Material Inspection: Verify the quality and specifications of raw materials, including coatings and substrates.

- Process Control: Monitor coating parameters such as thickness, temperature, and viscosity to maintain consistent application.

- In-Process Inspection: Conduct visual and non-destructive testing to identify defects early in the process.

- Final Product Inspection: Perform comprehensive inspections to assess coating appearance, adhesion, and other quality attributes.

- Documentation and Traceability: Maintain detailed records of all quality control data for traceability and compliance.

9. What are your experiences in troubleshooting and resolving coating-related issues?

In my previous role, I encountered a situation where the coating on a product was peeling prematurely. Through thorough troubleshooting, I identified that the substrate had not been properly prepared, resulting in poor adhesion. I implemented improved surface preparation methods, which resolved the issue and ensured the longevity of the coating.

10. How do you stay updated on the latest advancements in coating technology?

To stay updated on advancements in coating technology, I actively engage in industry events, webinars, and online resources. I subscribe to trade publications and participate in professional organizations to connect with experts and learn about new developments. Additionally, I seek opportunities for training and certification to enhance my knowledge and skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coating Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coating Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coating Machine Operators are responsible for operating and maintaining coating machines used in various industries to apply protective or decorative coatings to products. These machines require skilled operators to ensure efficient operation and high-quality results.

1. Machine Operation and Maintenance

Coating Machine Operators are responsible for the safe and efficient operation of coating machines, including setting up, monitoring, and adjusting machine parameters. They ensure that the machine is operating within specified tolerances and perform regular maintenance to prevent breakdowns and ensure optimal performance.

- Set up and calibrate coating machines according to product specifications.

- Monitor machine operation, including temperature, speed, and coating thickness, to ensure proper application.

- Adjust machine parameters to optimize coating quality and efficiency.

- Perform routine maintenance tasks such as cleaning, lubrication, and filter replacement.

2. Material Handling and Preparation

Coating Machine Operators handle and prepare coating materials, ensuring that the correct materials are used and that they meet quality standards. They also prepare and mix coating solutions according to specified formulas.

- Receive, inspect, and store coating materials.

- Prepare and mix coating solutions according to formulas.

- Load and unload materials into and out of coating machines.

- Monitor material usage and maintain inventory levels.

3. Quality Control and Inspection

Coating Machine Operators conduct quality control checks throughout the coating process to ensure that products meet customer specifications. They inspect coated products for defects, measure coating thickness, and make adjustments to the process as needed.

- Inspect coated products for defects, such as scratches, bubbles, or uneven coating.

- Measure coating thickness using specialized equipment.

- Make adjustments to machine settings or coating formulations based on inspection results.

- Maintain quality control records and provide documentation as required.

4. Safety and Environmental Compliance

Coating Machine Operators are responsible for maintaining a safe and environmentally compliant work area. They follow safety protocols, wear appropriate personal protective equipment (PPE), and dispose of hazardous materials properly.

- Follow safety protocols and wear appropriate PPE.

- Handle and dispose of hazardous materials according to regulations.

- Maintain a clean and organized work area.

- Report any safety hazards or environmental concerns.

Interview Tips

Preparing adequately for a Coating Machine Operator interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to research the company and the specific position you’re applying for. Understand the company’s products, services, and industry. Familiarize yourself with the job description and identify the key responsibilities and qualifications required.

- Visit the company’s website and social media pages.

- Read industry news and articles to gain insights into the company’s market position.

- Prepare questions to ask the interviewer about the company and the role.

2. Highlight Relevant Skills and Experience

In your resume and interview, emphasize your relevant skills and experience that align with the job requirements. Quantify your accomplishments whenever possible to demonstrate your impact. For example, instead of simply stating that you operated coating machines, you could say, “Operated coating machines and increased production efficiency by 15% through process optimization.”

- Review the job description carefully and identify the specific skills and qualifications that are required.

- Prepare examples from your previous experience that demonstrate how you meet these requirements.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

3. Practice Common Interview Questions

Anticipate common interview questions and prepare your answers in advance. This will help you feel more confident and articulate during the interview. Practice answering questions related to your skills, experience, motivations, and why you’re interested in the position.

- Prepare answers to questions about your technical skills, such as machine operation, quality control, and safety procedures.

- Practice answering questions about your problem-solving abilities and how you handle challenges.

- Be prepared to discuss your career goals and how this position aligns with them.

4. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally for your interview. Arrive on time, or even slightly early, to demonstrate your punctuality and respect for the interviewer’s time.

- Choose clothing that is clean, pressed, and appropriate for a professional setting.

- Arrive for your interview at least 10-15 minutes early.

- Bring a portfolio or resume to showcase your qualifications.

5. Be Enthusiastic and Ask Questions

Throughout the interview, maintain a positive and enthusiastic attitude. Show the interviewer that you’re genuinely interested in the position and the company. Engage with the interviewer by asking thoughtful questions about the role, the company culture, and the industry.

- Express your enthusiasm for the position and the company.

- Ask questions about the company’s products, services, and industry.

- Inquire about the company culture and work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Coating Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!