Are you gearing up for an interview for a Galvanizer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Galvanizer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

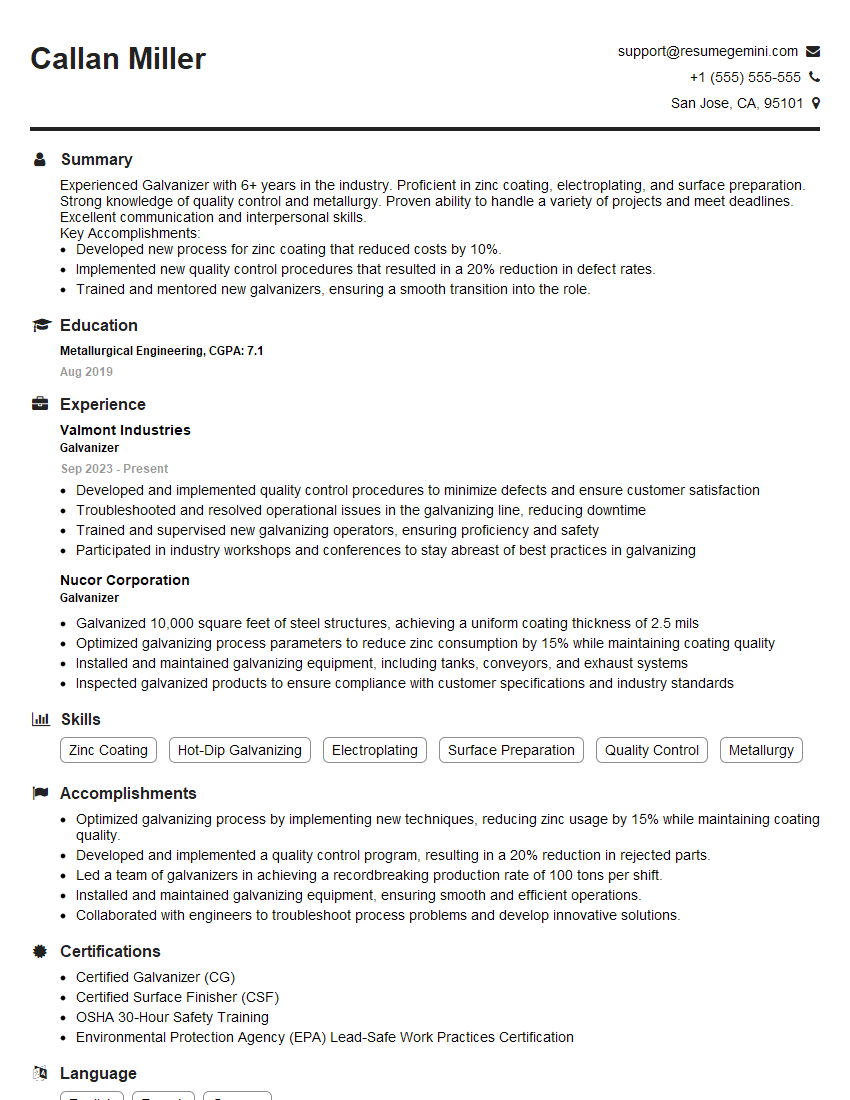

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Galvanizer

1. Explain the process of hot-dip galvanizing?

Hot-dip galvanizing is a process in which iron or steel is coated with a zinc layer to protect it from corrosion. The process involves dipping the metal into a molten zinc bath at a temperature of around 450°C (840°F). The zinc reacts with the iron or steel to form a series of intermetallic alloy layers, which are corrosion-resistant.

- The process involves several steps:

- The metal is first cleaned to remove any dirt, grease, or other contaminants.

- The metal is then fluxed, which helps to remove any oxides or other impurities from the surface of the metal.

- The metal is then dipped into the molten zinc bath. The zinc reacts with the iron or steel to form a series of intermetallic alloy layers, which are corrosion-resistant.

- The metal is then removed from the zinc bath and allowed to cool.

2. What are the advantages and disadvantages of hot-dip galvanizing?

Advantages

- Hot-dip galvanizing provides excellent corrosion protection.

- The zinc coating is durable and long-lasting.

- Hot-dip galvanizing is a relatively inexpensive process.

Disadvantages

- Hot-dip galvanizing can produce a rough surface finish.

- The process can be time-consuming.

- Hot-dip galvanizing can produce hazardous waste.

3. What are the different types of zinc coatings available?

There are several different types of zinc coatings available, including:

- G90 – This is the most common type of zinc coating. It is applied at a rate of 0.90 ounces per square foot of metal.

- G115 – This type of zinc coating is applied at a rate of 1.15 ounces per square foot of metal. It provides more corrosion protection than G90.

- G185 – This type of zinc coating is applied at a rate of 1.85 ounces per square foot of metal. It provides the most corrosion protection of all the zinc coatings.

4. What are the quality control procedures involved in hot-dip galvanizing?

There are several quality control procedures involved in hot-dip galvanizing, including:

- Visual inspection – This is a visual inspection of the galvanized coating to check for any defects.

- Thickness testing – This is a test to measure the thickness of the zinc coating.

- Adhesion testing – This is a test to measure the adhesion of the zinc coating to the metal.

- Salt spray testing – This is a test to measure the corrosion resistance of the zinc coating.

5. What is the difference between hot-dip galvanizing and electroplating?

Hot-dip galvanizing and electroplating are two different processes for coating metal with zinc. Hot-dip galvanizing involves dipping the metal into a molten zinc bath, while electroplating involves passing an electric current through a solution of zinc ions.

Hot-dip galvanizing produces a thicker zinc coating than electroplating, and the coating is more corrosion-resistant.

6. What are the hazards associated with hot-dip galvanizing?

There are several hazards associated with hot-dip galvanizing, including:

- Heat – The molten zinc bath is very hot, and workers can be exposed to burns.

- Zinc fumes – The zinc fumes can be harmful to workers’ health.

- Hazardous waste – The process can produce hazardous waste, which must be properly disposed of.

7. What are the regulations that govern hot-dip galvanizing?

There are several regulations that govern hot-dip galvanizing, including:

- OSHA – The Occupational Safety and Health Administration (OSHA) regulates the safety of workers who are exposed to hot-dip galvanizing.

- EPA – The Environmental Protection Agency (EPA) regulates the environmental impact of hot-dip galvanizing.

8. What is the future of hot-dip galvanizing?

Hot-dip galvanizing is a well-established process that has been used for over 100 years. The process is still widely used today, and it is expected to continue to be used in the future. However, there are some new technologies that are being developed that may eventually replace hot-dip galvanizing.

9. What are some of the common problems that can occur during hot-dip galvanizing?

There are several common problems that can occur during hot-dip galvanizing, including:

- Dross formation – Dross is a zinc-iron alloy that can form on the surface of the molten zinc bath. Dross can cause problems with the coating quality.

- Poor adhesion – The zinc coating may not adhere properly to the metal. This can be caused by a number of factors, including the surface preparation of the metal.

- Corrosion – The zinc coating can corrode over time. This can be caused by a number of factors, including the environment and the quality of the coating.

10. What are some of the new technologies that are being developed to replace hot-dip galvanizing?

There are several new technologies that are being developed to replace hot-dip galvanizing, including:

- Thermal diffusion galvanizing – This process uses a zinc-rich gas to coat the metal. The process is faster and more environmentally friendly than hot-dip galvanizing.

- Electroplating – This process uses an electric current to deposit a zinc coating on the metal. The process is more precise than hot-dip galvanizing and can produce a thinner coating.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Galvanizer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Galvanizer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Galvanizer plays a crucial role in protecting metal structures from corrosion and enhancing their durability. Their primary responsibilities include:

1. Hot-Dip Galvanizing Process

Thoroughly cleaning and preparing metal surfaces to ensure proper adhesion of the zinc coating.

2. Operation and Maintenance of Galvanizing Equipment

Operating and maintaining galvanizing lines, including furnaces, kettles, and handling equipment.

3. Quality Control and Inspection

Performing quality control checks to ensure the zinc coating meets specified standards and industry regulations.

4. Safety and Environmental Compliance

Adhering to all safety protocols and environmental regulations related to galvanizing operations.

Interview Tips

To prepare for a Galvanizer interview, consider these tips:

1. Research the Industry and Company

Understand the galvanizing process, its applications, and the company’s market position.

2. Highlight Relevant Skills and Experience

Emphasize your hands-on experience in hot-dip galvanizing, equipment operation, and quality control.

3. Prepare for Technical Questions

Brush up on your knowledge of zinc coating specifications, corrosion protection mechanisms, and safety protocols.

4. Practice Common Interview Questions

Prepare answers to typical interview questions about your motivations, strengths, weaknesses, and career goals.

5. Showcase Your Commitment to Safety

Discuss your understanding of galvanizing safety hazards and your commitment to following best practices.

6. Dress Professionally and Arrive Punctually

First impressions matter, so dress appropriately and be on time for your interview.

7. Ask Thoughtful Questions

Show your interest and engagement by asking insightful questions about the role, the company, and the industry.

8. Follow Up Promptly

Send a thank-you note within 24 hours of the interview, reiterating your interest and thanking the interviewer for their time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Galvanizer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!