Are you gearing up for an interview for a Electroplating Worker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Electroplating Worker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

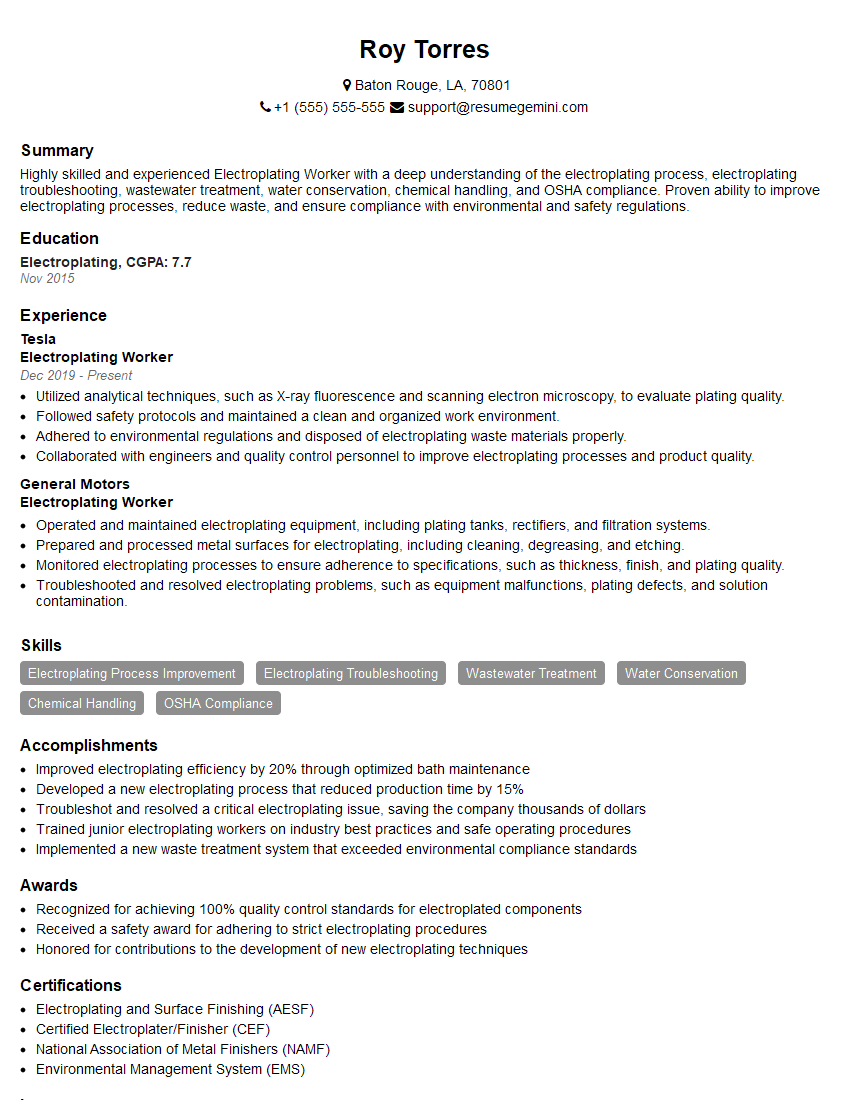

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electroplating Worker

1. Describe the process of electroplating in detail.

- Electroplating is an electrolytic process that uses an electric current to reduce dissolved metal ions to a solid metal coating on a conductive surface.

- The process involves using an anode made of the metal to be deposited and a cathode made of the object to be coated.

- An electrolyte solution containing metal ions is used, and an electric current is passed through the solution, causing the metal ions to be reduced and deposited on the cathode.

2. What are the different types of electroplating techniques?

Anodizing

- An electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish.

- The process forms a protective layer on the metal, increasing its resistance to wear and corrosion.

Chromating

- The process of applying a thin layer of chromium to a metal surface.

- It enhances the surface’s corrosion resistance, hardness, and wear resistance.

Electroless plating

- A chemical process that deposits a metal coating on a non-conductive surface.

- It uses a chemical reducing agent to reduce metal ions in a solution and deposit them on the surface.

3. What are the factors that affect the quality of electroplating?

- Surface preparation

- Electrolyte composition

- Current density

- Temperature

- Plating time

4. What are the safety precautions that must be followed during electroplating?

- Wear appropriate protective clothing, including gloves, apron, and eye protection.

- Ensure proper ventilation to avoid exposure to hazardous fumes.

- Handle chemicals and electrolytes with care.

- Dispose of waste materials properly.

5. What are the applications of electroplating?

- Decorative coatings

- Corrosion protection

- Electrical conductivity

- Wear resistance

- Soldering and welding

6. What are the different types of electrolytes used in electroplating?

- Acidic electrolytes (e.g., sulfuric acid, hydrochloric acid)

- Alkaline electrolytes (e.g., sodium hydroxide, potassium hydroxide)

- Neutral electrolytes (e.g., sodium chloride, potassium chloride)

7. What is the role of anodes in electroplating?

- Provide the metal ions for deposition

- Maintain the electrical conductivity of the electrolyte

- Prevent the build-up of passivation layers on the cathode

8. What are the advantages of using pulse plating over DC plating?

- Improved deposit quality

- Reduced internal stress

- Increased corrosion resistance

- Better adhesion

9. What are the common problems encountered in electroplating and how can they be solved?

- Poor adhesion: Ensure proper surface preparation and optimize the plating process.

- Pitting: Use high-quality chemicals, maintain proper electrolyte composition, and avoid contamination.

- Blistering: Control the current density, temperature, and plating time.

- Rough deposits: Use additives to the electrolyte, optimize the plating parameters, and ensure proper agitation.

10. What are the future trends in electroplating?

- Nanoplating

- Selective plating

- Environmentally friendly plating processes

- Advanced characterization techniques

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electroplating Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electroplating Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Electroplating Worker is responsible for the following key tasks:1. Preparing and Cleaning

Prepare metal surfaces for electroplating by cleaning, degreasing, and polishing them.

- Clean and prepare metal surfaces by removing dirt, grease, and other contaminants.

- Mask off non-plating areas to prevent them from being coated.

2. Electroplating

Operate electroplating equipment to apply metal coatings to surfaces.

- Immerse metal parts in electroplating baths and monitor the plating process.

- Adjust electrical current and voltage to achieve the desired coating thickness and quality.

3. Quality Control

Inspect and test electroplated surfaces to ensure they meet specifications.

- Measure and inspect plating thickness using gauges and other instruments.

- Perform adhesion, corrosion, and other tests to evaluate the quality of the plating.

4. Maintenance

Maintain and clean electroplating equipment and work areas.

- Inspect and clean electroplating baths, electrodes, and other equipment.

- Maintain proper chemical levels and temperatures in electroplating baths.

Interview Tips

To ace an interview for an Electroplating Worker position, follow these tips:1. Research the Company and Industry

Learn about the company’s products, services, and industry. This will help you understand their needs and tailor your answers accordingly.

- Visit the company’s website and LinkedIn page to gather information about their business and culture.

- Read industry publications and news to stay up-to-date on trends and best practices.

2. Highlight Your Skills and Experience

Emphasize your technical skills in electroplating, quality control, and maintenance. Quantify your accomplishments and provide specific examples of your work.

- Discuss your experience with different electroplating processes, such as electrodeposition, electroless plating, and anodizing.

- Highlight your knowledge of electroplating equipment, including power supplies, baths, and testing instruments.

3. Be Prepared to Talk About Safety

Electroplating can involve hazardous chemicals and processes. Show that you are aware of and committed to safety protocols.

- Describe your experience with handling and disposing of chemicals.

- Explain your understanding of the Material Safety Data Sheets (MSDS) and how you use them to ensure safety.

4. Practice Your Communication Skills

Electroplating Workers often work in teams and communicate with engineers, technicians, and customers. Demonstrate your ability to clearly explain technical concepts and collaborate with others.

- Prepare examples of how you have effectively communicated with colleagues and supervisors in previous roles.

- Practice answering questions about your understanding of electroplating processes in a concise and easy-to-understand manner.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Electroplating Worker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Electroplating Worker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.