Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hot Dip Galvanizer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

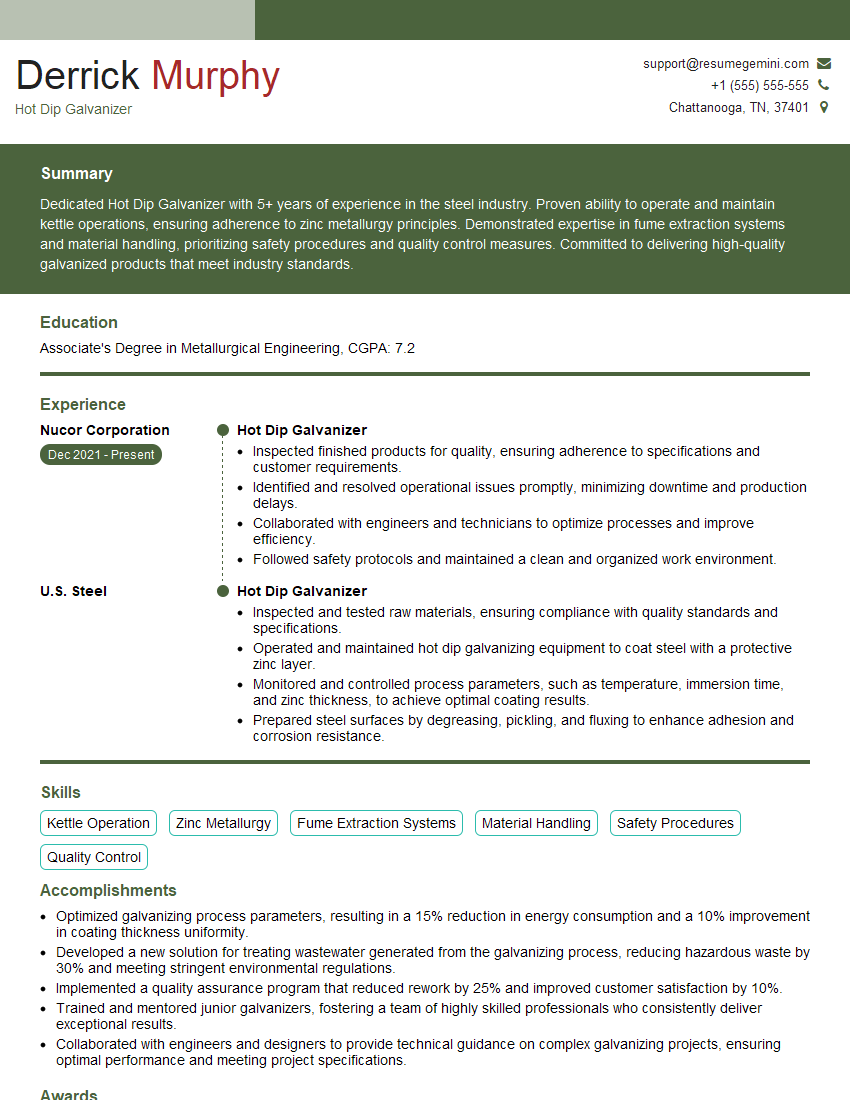

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hot Dip Galvanizer

1. Can you explain the basic principles of hot-dip galvanizing?

Hot-dip galvanizing involves immersing steel or iron in a molten zinc bath to create a protective layer. This layer helps prevent corrosion and extends the life of the metal.

2. Describe the different types of hot-dip galvanizing processes.

Batch galvanizing

- Involves dipping individual pieces into the molten zinc bath.

Continuous galvanizing

- Used for mass production of galvanized steel.

- A continuous strip of steel is passed through the molten zinc bath.

Galvannealing

- Similar to hot-dip galvanizing but involves a post-annealing step.

- Results in a softer and more ductile coating.

3. What are the key parameters that affect the quality of the galvanized coating?

- Temperature of the molten zinc

- Immersion time

- Composition of the zinc bath

- Surface preparation of the steel

- Post-treatment processes

4. How do you ensure that the galvanized coating meets industry standards?

- Following standardized procedures

- Conducting regular testing and quality control checks

- Adhering to specific coating thickness requirements

- Complying with relevant industry codes and specifications

5. What are the common defects that can occur during hot-dip galvanizing?

- Adhesion problems

- Dross inclusions

- Zinc spangles

- Slag entrapment

6. How do you troubleshoot and resolve galvanizing defects?

- Identifying the root cause

- Implementing corrective measures

- Adjusting parameters (e.g., temperature, immersion time)

- Modifying pretreatment processes

7. What are the safety precautions that need to be taken during hot-dip galvanizing?

- Wearing appropriate protective gear

- Proper ventilation and exhaust systems

- Handling molten zinc with extreme care

- Maintaining a clean and organized work environment

8. What is the importance of proper surface preparation before galvanizing?

- Ensures good adhesion of the zinc coating

- Removes contaminants and oxides

- Improves the corrosion resistance of the steel

9. How do you handle and store galvanized materials?

- Using proper lifting techniques

- Protecting from mechanical damage

- Storing in a dry and well-ventilated area

- Preventing exposure to corrosive environments

10. What are the environmental considerations for hot-dip galvanizing?

- Managing zinc waste responsibly

- Minimizing air emissions

- Complying with environmental regulations

11. Describe the quality control procedures you implement to ensure the consistency of the galvanizing process.

- Regular testing of molten zinc bath chemistry

- Monitoring immersion times and temperatures

- Visual inspection of finished products

- Adhesion and thickness testing

- Record-keeping and documentation

12. Explain the advantages and disadvantages of hot-dip galvanizing compared to other corrosion protection methods.

Advantages

- Excellent corrosion resistance

- Long service life

- Cathodic protection

- Cost-effective

Disadvantages

- Can be brittle if not properly applied

- May require touch-ups over time

- Not suitable for all applications (e.g., where high temperatures are involved)

13. What is the role of alloying elements in hot-dip galvanizing?

- Improving the corrosion resistance

- Enhancing the mechanical properties

- Modifying the coating appearance

14. Discuss the factors that influence the thickness of the galvanized coating.

- Steel composition

- Immersion time

- Zinc bath temperature

- Agitation of the zinc bath

15. What are the latest advancements in hot-dip galvanizing technology?

- Ultra-high strength galvanized steel

- Controlled cooling processes

- Environmental-friendly zinc alloys

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hot Dip Galvanizer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hot Dip Galvanizer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hot Dip Galvanizer is responsible for ensuring the proper galvanization of metal products. Primary duties include preparing the metal, immersing it in molten zinc, and post-treatment processes. The goal is to protect the metal from corrosion and ensure its longevity.

1. Metal Preparation

Prior to galvanization, the metal must be thoroughly cleaned. This involves removing dirt, grease, and rust. A variety of methods may be used, including chemical cleaning, pickling, and sandblasting.

2. Fluxing

To ensure proper adhesion of the zinc to the metal, a flux is applied prior to dipping. Fluxing agents remove surface oxides and promote a metallurgical bond between the zinc and the substrate.

3. Hot Dip Galvanizing

The prepared metal is immersed into a molten zinc bath. The temperature of the bath is precisely controlled to ensure optimal coating thickness and adhesion. The duration of immersion is also critical and varies based on the size and type of metal being galvanized.

4. Post-Treatment Processes

After the metal has been galvanized, it may undergo additional post-treatment processes, such as quenching, tempering, or chromating. These processes improve the corrosion resistance, hardness, and overall durability of the galvanized coating.

5. Quality Control

Hot Dip Galvanizers must adhere to strict quality control standards. This includes testing the galvanized coating thickness, adhesion, and corrosion resistance. Regular monitoring of the galvanizing bath and equipment is also essential to ensure consistent and high-quality results.

Interview Tips

To ace a Hot Dip Galvanizer interview, preparation is key. Here are some tips to help you succeed:

1. Research the Company and Role

Familiarize yourself with the company’s history, values, and current projects. Understand the specific requirements of the Hot Dip Galvanizer role and how it aligns with your skills and experience.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in metal preparation techniques, fluxing, and hot dip galvanizing processes. Showcase your knowledge of quality control standards and safety procedures. If you have experience with different types of metals, equipment, or post-treatment processes, be sure to mention them.

3. Prepare for Technical Questions

Anticipate questions related to the galvanizing process, such as the different stages involved, the role of flux, and the factors that affect coating thickness and adhesion. You may also be asked about your understanding of quality control procedures and your ability to troubleshoot problems.

4. Demonstrate Your Safety Consciousness

Hot Dip Galvanizing involves working with molten metal and hazardous chemicals. Employers will be keen to assess your safety awareness and commitment to following proper procedures. Share examples of your safety practices and how you have contributed to a safe work environment.

5. Be Prepared to Discuss Your Career Goals

Articulate your career aspirations and how this role fits into your long-term plans. Show enthusiasm for the field and a willingness to learn and grow in your profession.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Hot Dip Galvanizer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Hot Dip Galvanizer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.