Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Impregnation Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Impregnation Operator so you can tailor your answers to impress potential employers.

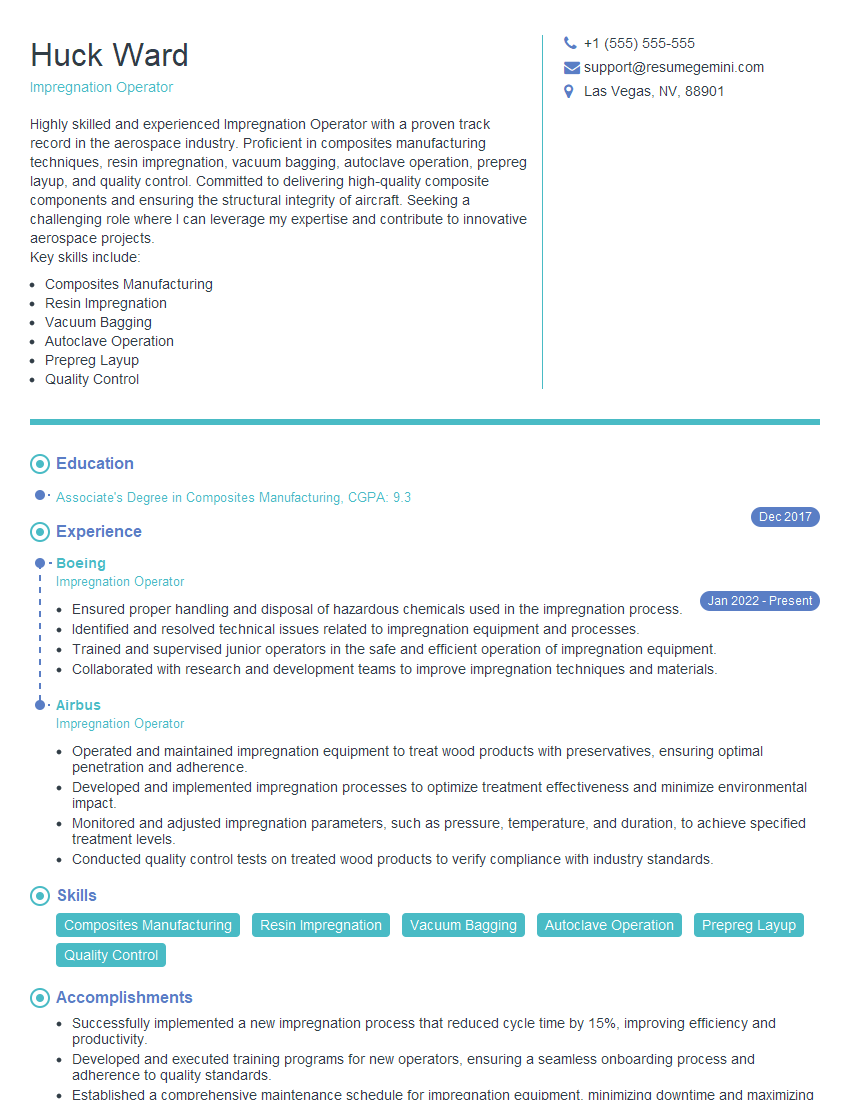

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Impregnation Operator

1. What are the different types of impregnation processes?

- Vacuum impregnation

- Pressure impregnation

- Immersion impregnation

2. What are the key process parameters in impregnation?

Vacuum

- Vacuum level

- Vacuum hold time

Pressure

- Pressure level

- Pressure hold time

Immersion

- Immersion time

- Temperature

3. How do you measure the quality of impregnation?

- Visual inspection

- Ultrasonic testing

- Mechanical testing

4. What are the common defects in impregnation?

- Voids

- Cracks

- Inclusions

5. How do you troubleshoot defects in impregnation?

- Identify the source of the defect

- Determine the root cause of the defect

- Implement corrective actions to eliminate the defect

6. What are the safety precautions that must be taken when operating impregnation equipment?

- Wear appropriate personal protective equipment (PPE)

- Follow all operating instructions

- Be aware of the hazards associated with impregnation chemicals

7. What is your experience with operating impregnation equipment?

- Describe your experience with different types of impregnation equipment

- Highlight your knowledge of impregnation process parameters

- Explain your ability to troubleshoot defects in impregnation

8. What are your quality control procedures for impregnation?

- Describe your inspection methods for impregnated products

- Explain how you ensure that impregnated products meet the required specifications

- Discuss your procedures for corrective action when defects are found

9. What are the challenges in impregnation?

- Achieving uniform impregnation

- Preventing defects

- Maintaining process efficiency

10. How do you stay up-to-date on the latest advances in impregnation technology?

- Attend industry conferences and workshops

- Read technical journals and articles

- Network with other professionals in the field

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Impregnation Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Impregnation Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Impregnation Operators play a crucial role in the production process by impregnating paper or other materials with resin or other chemicals. Their responsibilities encompass a wide range of tasks that ensure the smooth operation of the impregnation line and the production of high-quality products.

1. Impregnation Process Management

Impregnation Operators are responsible for overseeing the impregnation process, ensuring that paper or other materials are properly coated with resin or other chemicals. This involves:

- Preparing and mixing impregnation solutions

- Setting up and operating impregnation equipment

- Monitoring and controlling impregnation parameters such as temperature, pressure, and speed

- Ensuring that impregnation meets specified requirements

2. Machine Operation and Maintenance

Impregnation Operators are responsible for the operation and maintenance of impregnation equipment. This includes:

- Starting, stopping, and adjusting impregnation machines

- Performing routine maintenance and repairs

- Identifying and troubleshooting operational problems

- Follow established maintenance schedules and procedures

3. Product Handling and Quality Control

Impregnation Operators are responsible for handling and inspecting impregnated products. This involves:

- Unloading and stacking impregnated materials

- Checking for defects or damage

- Taking samples for quality control

- Maintaining records of impregnation and quality control data

4. Safety and Compliance

Impregnation Operators are responsible for adhering to safety and environmental regulations. This includes:

- Wearing appropriate personal protective equipment

- Following safe work practices

- Handling and disposing of chemicals properly

- Complying with environmental regulations and standards

Interview Tips

Preparing for an interview for an Impregnation Operator position requires a thorough understanding of the job responsibilities and the industry. Here are some tips and hacks to help you ace the interview:

1. Research the Company and Role

Research the company’s history, products, and industry standing. Learn about the specific role and the responsibilities associated with it. This will demonstrate your interest and show that you have taken the time to prepare.

2. Highlight Relevant Experience and Skills

Carefully review the job description and identify the key skills and qualifications required. Highlight your experience and skills that align with these requirements. Quantify your accomplishments and provide specific examples of your contributions in previous roles.

3. Practice Answering Common Interview Questions

Prepare for common interview questions such as “Tell me about yourself,” “Why are you interested in this role,” and “What makes you a good fit for this company.” Practice your answers by rehearsing out loud or with a friend. This will boost your confidence and ensure that you deliver clear and concise responses.

4. Prepare Industry-Specific Questions

Research the impregnation industry and be ready to ask thoughtful questions about the company’s processes, technologies, and market trends. This shows that you are knowledgeable and genuinely interested in the field.

5. Demonstrate Safety and Compliance Awareness

Impregnation Operators are responsible for adhering to safety and environmental regulations. Emphasize your understanding of safety protocols, handling and disposal of chemicals, and compliance with industry standards. This demonstrates your commitment to workplace safety and environmental stewardship.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Impregnation Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Impregnation Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.