Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lock Plater position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

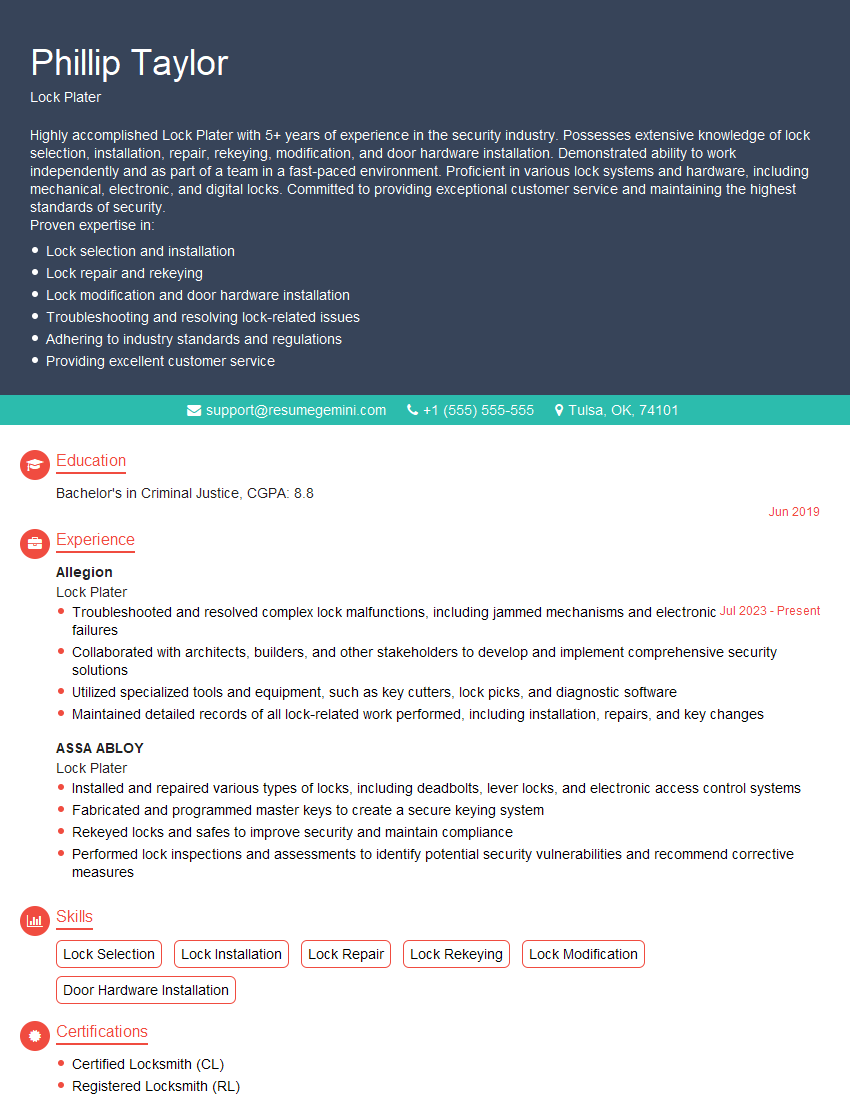

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lock Plater

1. What are the different types of locks that you are familiar with and can install?

- Deadbolts

- Doorknobs

- Lever handles

- Padlocks

- Chain locks

- Combination locks

- Keyless entry locks

2. What are the different materials that locks can be made of?

Metals

- Steel

- Brass

- Aluminum

Non-metals

- Plastic

- Wood

- Laminate

3. What are the different finishes that locks can have?

- Polished

- Brushed

- Antiqued

- Painted

- Powder-coated

4. What are the different security features that locks can have?

- Bump-proof

- Pick-proof

- Drill-proof

- Key control

- Master keying

5. What are the different types of lock installations that you can perform?

- New lock installation

- Lock replacement

- Lock repair

- Key duplication

- Master keying

6. What are the different types of lock maintenance that you can perform?

- Lock lubrication

- Lock cleaning

- Lock adjustment

- Lock inspection

- Lock repair

7. What are the different types of lock troubleshooting that you can perform?

- Lock not opening

- Lock not locking

- Key not turning

- Key broken in lock

- Lock jammed

8. What are the different types of lock codes and how do you use them?

- Key codes

- Combination codes

- Electronic codes

9. What are the different types of lockpicking tools and how do you use them?

- Tension wrenches

- Picking tools

- Bump keys

10. What are the different types of lockpick safes and how do you open them?

- Mechanical safes

- Electronic safes

- Combination safes

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lock Plater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lock Plater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lock Platers are responsible for plating metal objects with a thin layer of metal to improve their appearance, durability, and corrosion resistance. They use specialized equipment and techniques to apply a variety of metals to surfaces, including copper, silver, gold, and nickel.

1. Electroplating

Electroplating involves submerging a metal object in a solution containing dissolved metal ions. An electric current is then passed through the solution, causing the metal ions to deposit on the surface of the object.

- Prepare metal objects for electroplating by cleaning, degreasing, and rinsing them.

- Set up and operate electroplating equipment, including tanks, rectifiers, and timers.

- Monitor the electroplating process to ensure it is carried out according to specifications.

2. Barrel Plating

Barrel plating is a type of electroplating that is used to plate small, irregularly shaped objects. The objects are placed in a rotating barrel that is submerged in the plating solution. As the barrel rotates, the objects are agitated, which helps to ensure that they are evenly plated.

- Load and unload barrels with small parts.

- Operate barrel plating equipment, including barrels, rectifiers, and timers.

- Monitor the barrel plating process to ensure it is carried out according to specifications.

3. Electroless Plating

Electroless plating is a type of plating that does not require the use of an electric current. Instead, a chemical reaction is used to deposit the metal ions on the surface of the object.

- Prepare metal objects for electroless plating by cleaning, degreasing, and rinsing them.

- Set up and operate electroless plating equipment, including tanks, pumps, and filters.

- Monitor the electroless plating process to ensure it is carried out according to specifications.

4. Quality Control

Lock Platers are responsible for ensuring that the plated objects meet the required quality standards. They visually inspect the objects for defects, such as blisters, cracks, and peeling. They also perform thickness tests to ensure that the plating is of the correct thickness.

- Inspect plated objects for defects.

- Perform thickness tests to ensure that the plating is of the correct thickness.

- Maintain records of all quality control inspections.

Interview Tips

Preparing for an interview for a Lock Plater position can help you present yourself confidently and increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the Company and Position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals. You should also familiarize yourself with the job description and the key responsibilities of the position.

2. Practice Answering Common Interview Questions

There are a few common interview questions that you can expect to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your responses confidently and clearly.

3. Highlight Your Skills and Experience

During your interview, be sure to highlight your skills and experience that are relevant to the Lock Plater position. This includes your technical skills, such as your knowledge of electroplating and barrel plating, as well as your quality control experience. You should also emphasize your soft skills, such as your attention to detail, your ability to work independently, and your teamwork skills.

4. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic about the position and who are a good fit for the company culture. Be sure to convey your excitement about the opportunity and your desire to contribute to the company’s success. You should also be positive and upbeat throughout the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lock Plater interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!