Are you gearing up for a career in Lubricating Machine Tender? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Lubricating Machine Tender and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

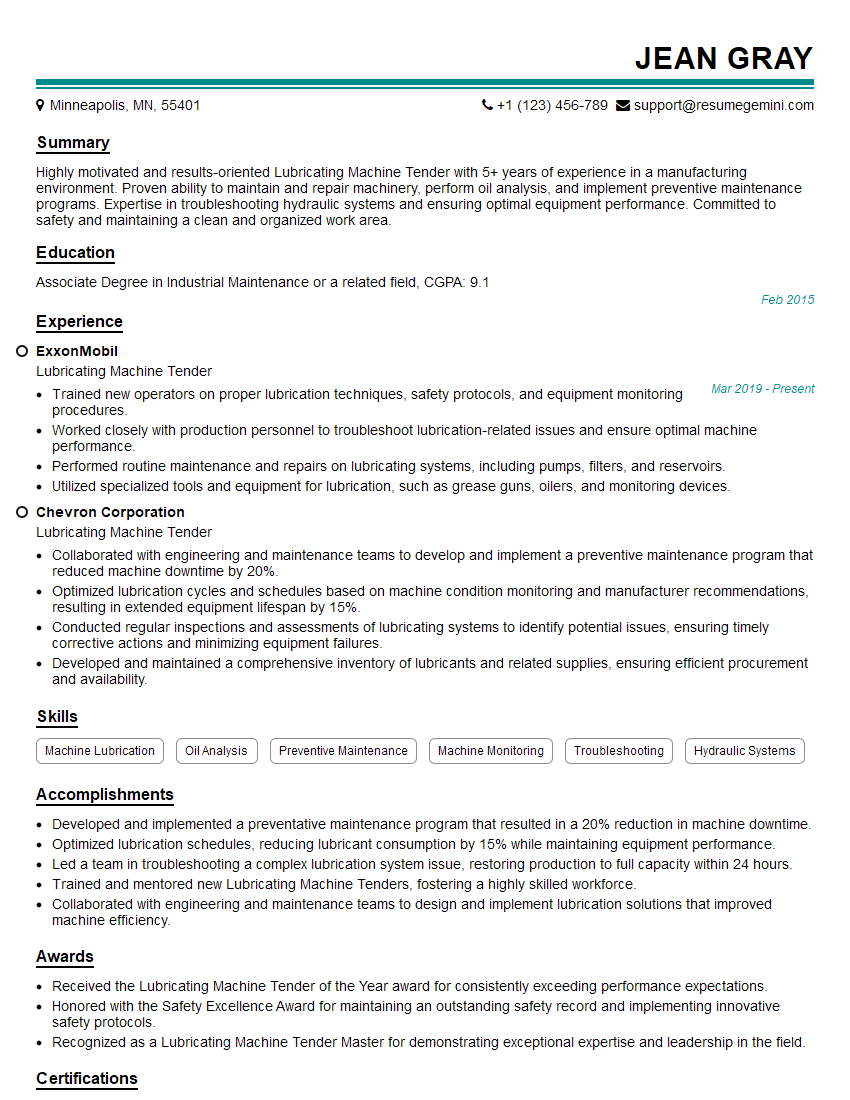

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lubricating Machine Tender

1. Explain the process of lubricating machines?

The process of lubricating machines involves the following steps:

- Identifying the lubrication points on the machine.

- Selecting the appropriate lubricant for the application.

- Applying the lubricant to the lubrication points.

- Monitoring the lubrication system to ensure that it is functioning properly.

2. What are the different types of lubricants?

Synthetic lubricants

- Designed to perform under extreme conditions.

- Can be more expensive than other types of lubricants.

Mineral-based lubricants

- Made from refined crude oil.

- Less expensive than synthetic lubricants.

Bio-based lubricants

- Made from renewable resources.

- More environmentally friendly than other types of lubricants.

3. What are the factors to consider when selecting a lubricant?

- The type of machine

- The operating conditions

- The desired performance characteristics

- The cost

4. What are the consequences of using the wrong lubricant?

- Increased wear and tear on the machine

- Reduced machine efficiency

- Increased downtime

- Potential safety hazards

5. What are the safety precautions that must be taken when working with lubricants?

- Wear appropriate personal protective equipment (PPE).

- Avoid skin contact with lubricants.

- Do not ingest lubricants.

- Keep lubricants away from open flames and sparks.

- Dispose of lubricants properly.

6. What are the different methods of applying lubricants?

- Manual lubrication

- Automatic lubrication

- Centralized lubrication

7. What are the advantages and disadvantages of manual lubrication?

Advantages

- Low cost

- Simple to implement

Disadvantages

- Time-consuming

- Inconsistent application

- Can be hazardous

8. What are the advantages and disadvantages of automatic lubrication?

Advantages

- Consistent application

- Reduced downtime

- Improved machine efficiency

Disadvantages

- Higher cost

- More complex to implement

9. What are the advantages and disadvantages of centralized lubrication?

Advantages

- Consistent application

- Reduced downtime

- Improved machine efficiency

- Lower maintenance costs

Disadvantages

- Higher cost

- More complex to implement

10. What are the latest trends in lubrication technology?

- The development of new lubricants that are more environmentally friendly.

- The development of new lubrication systems that are more efficient and effective.

- The use of condition monitoring to optimize lubrication practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lubricating Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lubricating Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Lubricating Machine Tender is responsible for operating and maintaining machines that apply lubricants to metal surfaces. Their key responsibilities include:

1. Lubricating Machinery

Lubricating Machine Tenders are responsible for lubricating machines to reduce friction and wear. They must have a good understanding of the different types of lubricants and their properties, and be able to apply them correctly to various types of machinery.

- Selecting and applying lubricants

- Monitoring lubricant levels

- Maintaining lubrication systems

2. Maintaining Equipment

Lubricating Machine Tenders are also responsible for maintaining the equipment they use. They must be able to troubleshoot and repair basic problems, and perform scheduled maintenance tasks.

- Inspecting equipment for wear and damage

- Performing preventive maintenance tasks

- Repairing minor equipment problems

3. Monitoring Production

Lubricating Machine Tenders must monitor production to ensure that machines are running smoothly. They must be able to identify and correct any problems that arise, and take action to prevent future problems.

- Observing machines for signs of trouble

- Taking corrective action to prevent problems

- Reporting production problems to supervisors

4. Safety and Quality Assurance

Lubricating Machine Tenders must follow safety procedures and maintain a clean and organized work area. They must also be able to produce high-quality work, and be willing to work with others to achieve production goals.

- Following safety procedures

- Maintaining a clean and organized work area

- Producing high-quality work

Interview Tips

To ace an interview for a Lubricating Machine Tender position, you should:

1. Highlight Your Experience

If you have any experience working with machinery or in a manufacturing environment, be sure to highlight this in your interview. You should also mention any specific skills or knowledge that you have that would be relevant to the job, such as experience with lubrication or maintenance.

- Example: “In my previous role, I was responsible for lubricating and maintaining a variety of machines in a manufacturing environment. I have a good understanding of the different types of lubricants and their properties, and I am proficient in applying them correctly to various types of machinery.”

2. Demonstrate Your Knowledge

The interviewer will likely ask you questions about your knowledge of lubrication and machinery. Be sure to answer these questions clearly and concisely, and provide examples to support your answers. You should also be prepared to discuss any specific knowledge or experience that you have that would be relevant to the job.

- Example: “I am familiar with the different types of lubricants and their properties, and I understand how to apply them correctly to different types of machinery. I also have experience troubleshooting and repairing basic equipment problems.”

3. Show Your Safety Awareness

Safety is a top priority in any manufacturing environment, so be sure to demonstrate your safety awareness in your interview. You should be familiar with the safety procedures that are relevant to the job, and you should be able to explain how you would follow these procedures to keep yourself and others safe.

- Example: “I am familiar with the safety procedures that are relevant to this job, and I am always careful to follow these procedures to keep myself and others safe. I am also aware of the potential hazards associated with working with machinery, and I take steps to minimize these hazards.”

4. Be Detail-Oriented

Lubricating Machine Tenders must be detail-oriented to ensure that machinery is running smoothly and efficiently. In your interview, be sure to demonstrate your attention to detail. You should be able to provide examples of how you have used your attention to detail to improve your work performance.

- Example: “I am very detail-oriented, and I take pride in my work. I always pay close attention to the details of my tasks, and I always make sure that my work is done to the highest possible standard.”

Next Step:

Now that you’re armed with the knowledge of Lubricating Machine Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Lubricating Machine Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini