Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Metal Sprayer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Metal Sprayer so you can tailor your answers to impress potential employers.

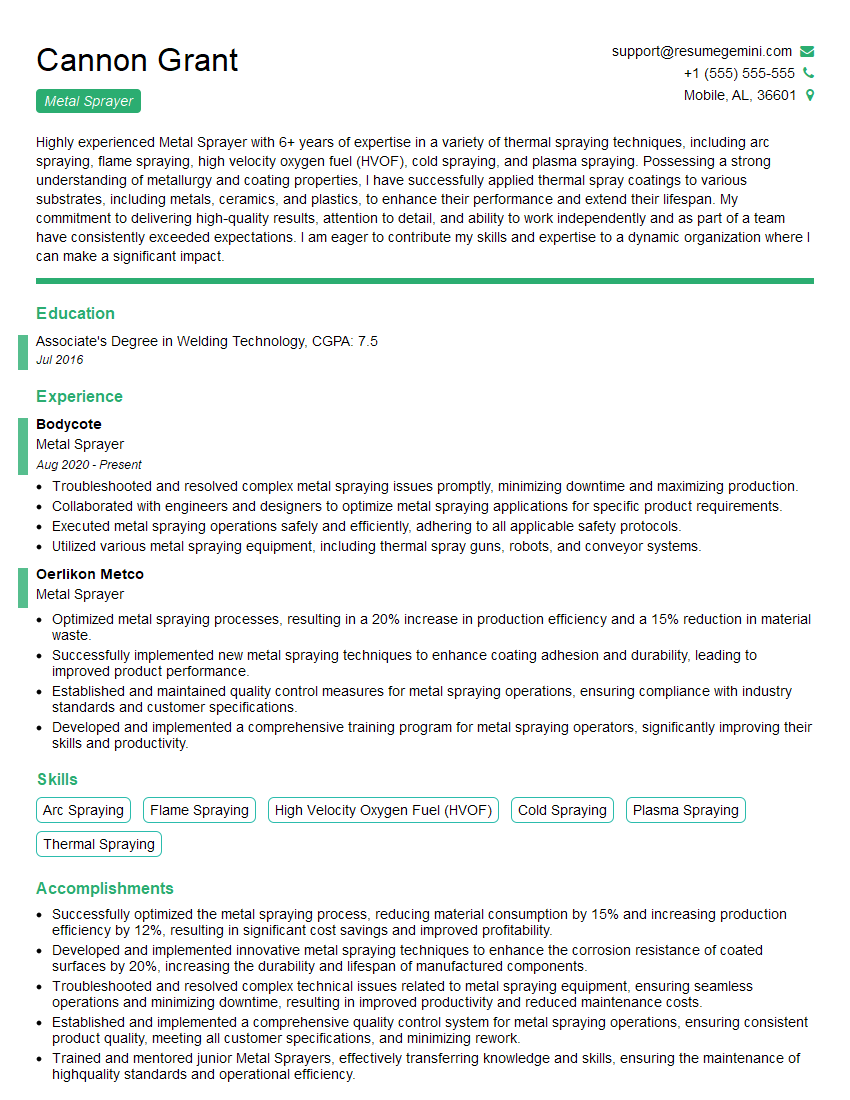

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Sprayer

1. Explain the different types of metal spraying techniques?

There are several types of metal spraying techniques, including:

- Arc spraying: Uses an electric arc to melt metal wire, which is then atomized and sprayed onto the surface. This method is suitable for spraying a wide range of metals.

- Flame spraying: Uses a combination of fuel and oxygen to heat and melt metal powder, which is then sprayed onto the surface. This method is commonly used for spraying aluminum and zinc.

- Detonation gun spraying: Uses a high-explosive charge to create a shock wave that atomizes and sprays metal powder onto the surface. This method is used for spraying hard and wear-resistant materials such as tungsten carbide and chromium carbide.

- Plasma spraying: Uses a plasma arc to generate high temperatures that melt and atomize metal powder, which is then sprayed onto the surface. This method is suitable for spraying a wide range of materials, including metals, ceramics, and polymers.

- Cold spraying: Uses a supersonic gas jet to accelerate metal particles onto the surface, where they deform and bond together. This method is suitable for spraying materials that are sensitive to heat, such as polymers and biomaterials.

2. What are the key factors that affect the quality of a metal sprayed coating?

Surface preparation:

- Ensuring the surface is clean, free of contaminants, and has the appropriate surface roughness.

Metal powder characteristics:

- Particle size, shape, and composition can affect the coating’s properties.

Spray parameters:

- Gas flow rates, spray distance, and traverse speed can influence the coating’s thickness, porosity, and adhesion.

Equipment maintenance:

- Regular calibration and maintenance of the spray equipment is essential for consistent coating quality.

3. How do you determine the thickness of a metal sprayed coating?

There are several methods for determining the thickness of a metal sprayed coating, including:

- Magnetic thickness gauge: Uses a magnetic field to measure the thickness of non-magnetic coatings on ferrous substrates.

- Eddy current thickness gauge: Uses electromagnetic induction to measure the thickness of conductive coatings on both ferrous and non-ferrous substrates.

- Micrometer or calipers: Can be used to measure the thickness of coatings that are thick enough to be measured mechanically.

4. What are the common defects that can occur in metal sprayed coatings, and how can they be prevented?

Common defects in metal sprayed coatings include:

- Porosity: Can be caused by entrapped air or moisture, insufficient spray distance, or incorrect gas flow rates.

- Adhesion problems: Can be caused by poor surface preparation, improper spray parameters, or contamination.

- Oxidation: Can occur when the coating is exposed to high temperatures or oxidizing environments.

These defects can be prevented by proper surface preparation, optimizing spray parameters, using appropriate materials, and applying post-spray treatments such as sealing or heat treatment.

5. What are the advantages of using metal spraying over other coating methods?

- Versatile: Can be used to apply a wide range of metals and alloys to various substrates.

- Cost-effective: Can be more economical than other coating methods, especially for large or complex surfaces.

- Customizable: Coatings can be tailored to meet specific performance requirements.

- Efficient: Can be applied quickly and efficiently, reducing downtime.

6. What are the safety precautions that need to be taken when metal spraying?

- Wear appropriate protective gear: Including a respirator, gloves, and safety glasses.

- Ensure proper ventilation: To remove harmful fumes and dust.

- Handle flammable materials safely: Including fuels and compressed gases.

- Follow manufacturer’s instructions: For safe operation of the metal spraying equipment.

7. Describe your experience with different metal spraying techniques.

I have experience with various metal spraying techniques, including arc spraying, flame spraying, and plasma spraying. I have used these techniques to apply a wide range of metals and alloys, including steel, aluminum, zinc, and tungsten carbide.

In my previous role, I was responsible for metal spraying components for the aerospace industry. I used arc spraying to apply a wear-resistant coating to landing gear components, and plasma spraying to apply a thermal barrier coating to jet engine components.

8. How do you troubleshoot common problems that occur during metal spraying?

When troubleshooting common problems that occur during metal spraying, I follow a systematic approach:

- Identify the problem: Observe the coating and identify the specific defect or issue.

- Inspect the equipment: Check the spray gun, hoses, and power supply for any damage or malfunctions.

- Review the spray parameters: Ensure that the gas flow rates, spray distance, and traverse speed are within the recommended ranges.

- Examine the metal powder: Check the particle size, shape, and composition to ensure they are suitable for the application.

- Inspect the surface preparation: Verify that the substrate is clean, free of contaminants, and has the appropriate surface roughness.

9. How do you stay updated on the latest metal spraying technologies and developments?

- Attend industry conferences and workshops: To learn about new techniques, equipment, and applications.

- Read technical journals and articles: To stay informed about advancements in the field.

- Consult with equipment manufacturers and suppliers: To get insights into the latest technologies and developments.

- Engage in online forums and discussions: To connect with other professionals and exchange knowledge.

10. What are your career goals and how does this role align with them?

My career goal is to become a leading expert in the field of metal spraying. I am passionate about using this technology to solve complex engineering problems and improve the performance and durability of various components and structures.

This role aligns with my career goals as it provides me with the opportunity to work on challenging projects, contribute to the advancement of metal spraying technology, and make a significant impact in the industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Sprayer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Sprayer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Metal Sprayer is responsible for applying a protective coating of metal onto various surfaces using a specialized spray gun. This involves preparing the surface, selecting the appropriate metal material, and operating the equipment to achieve the desired finish.

1. Surface Preparation

Ensures proper surface preparation by cleaning, degreasing, and roughening the surface to enhance adhesion.

2. Metal Selection and Application

Selects the appropriate metal material based on the surface type, desired coating properties, and industry standards.

Operates the spray gun to apply the metal coating evenly and effectively, meeting the specified thickness and coverage requirements.

3. Equipment Maintenance and Troubleshooting

Maintains and cleans the spray gun and related equipment regularly to ensure optimal performance.

Troubleshoots and resolves any technical issues related to the equipment or the coating process.

4. Safety Compliance

Adheres to all safety protocols and guidelines related to the handling of metal materials and the operation of spray gun equipment.

Uses appropriate personal protective equipment (PPE) and follows proper ventilation practices.

Interview Tips

To ace the Metal Sprayer interview, candidates should follow these tips:

1. Research the Company and Role

Thoroughly research the company’s background, industry, and the specific role requirements.

2. Practice Technical Skills

Review and refresh your knowledge of metal spraying techniques, surface preparation methods, and safety procedures.

3. Highlight Your Expertise

Quantify your experience and accomplishments in metal spraying, including the types of projects you’ve worked on and the results you achieved.

4. Be Ready for Safety Questions

Anticipate questions about your safety practices and knowledge of industry regulations. Prepare examples of how you prioritize safety in your work.

5. Ask Thoughtful Questions

During the interview, ask insightful questions that demonstrate your interest in the company, the role, and the industry.

6. Dress Professionally

Dress appropriately for the interview, as it reflects your professionalism and respect for the position.

7. Be Punctual and Enthusiastic

Arrive on time for the interview and demonstrate your enthusiasm for the opportunity.

8. Follow Up

After the interview, send a thank-you note to the interviewer reiterating your interest and highlighting your key qualifications.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Sprayer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.