Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Oxidized Finish Plater interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Oxidized Finish Plater so you can tailor your answers to impress potential employers.

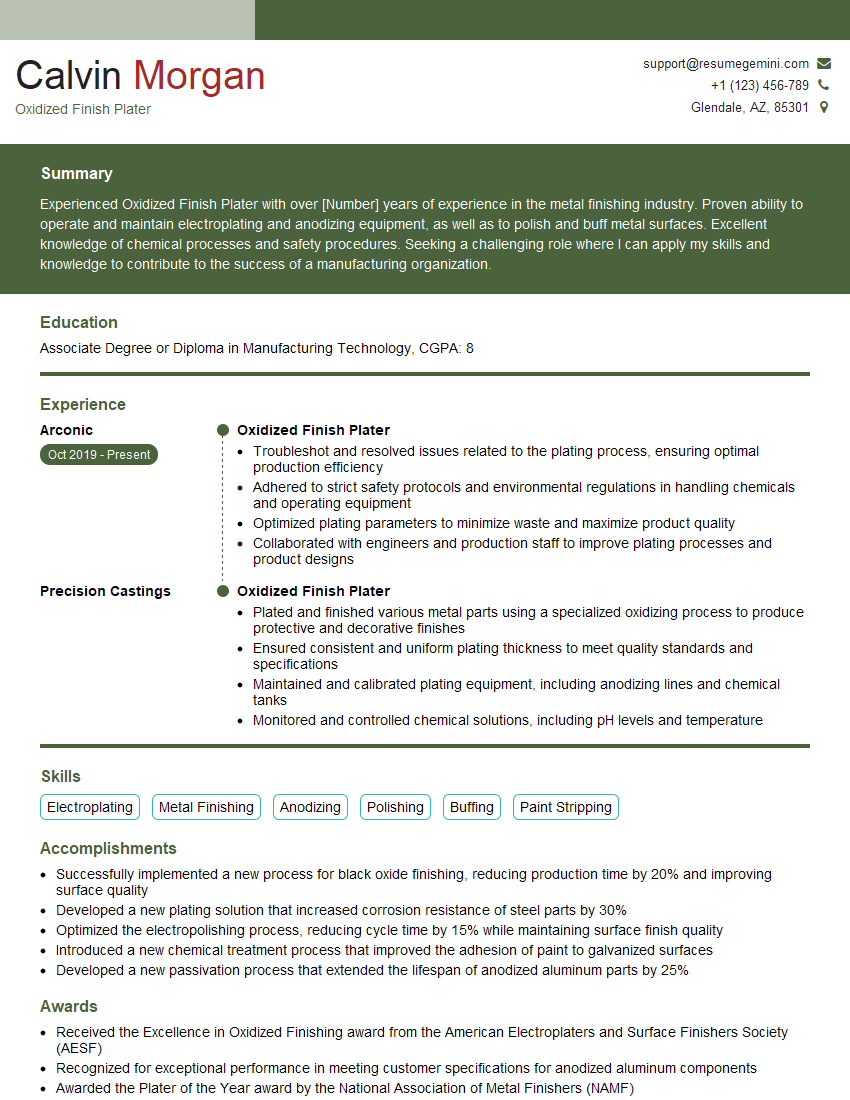

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oxidized Finish Plater

1. What are the different types of oxidizing agents used in oxidized finish plating?

- Chromic acid

- Nitric acid

- Sulfuric acid

- Hydrogen peroxide

2. What are the different factors that can affect the thickness of the oxide layer?

- Concentration of the oxidizing agent

- Temperature of the solution

- Duration of the oxidation process

3. What are the methods used to control the color of the oxide layer?

- Varying the concentration of the oxidizing agent

- Varying the temperature of the solution

- Adding colorants to the solution

4. What are the different methods used to apply oxidized finishes?

- Chemical oxidation

- Electrochemical oxidation

- Thermal oxidation

5. What are the different applications of oxidized finishes?

- Decorative purposes

- Corrosion protection

- Electrical insulation

6. What are the safety precautions that need to be taken when working with oxidizing agents?

- Wear appropriate personal protective equipment

- Handle oxidizing agents with care

- Store oxidizing agents in a safe location

7. What are the different types of equipment used in oxidized finish plating?

- Plating tanks

- Power supplies

- Ventilation systems

8. What are the different quality control tests that are performed on oxidized finishes?

- Visual inspection

- Thickness measurement

- Corrosion resistance testing

9. What are the troubleshooting tips for oxidized finish plating?

- Check the concentration of the oxidizing agent

- Check the temperature of the solution

- Check the duration of the oxidation process

10. What are the future trends in oxidized finish plating?

- Use of more environmentally friendly oxidizing agents

- Development of new methods to control the thickness and color of the oxide layer

- Expansion of the applications of oxidized finishes

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oxidized Finish Plater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oxidized Finish Plater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Oxidized Finish Platers use chemical and electrolytic processes to treat and color metal surfaces.

1. Surface Preparation

Preparing the metal surface for plating involves cleaning, degreasing, and etching techniques to remove impurities and ensure a smooth, receptive surface.

- Cleaning and degreasing metal surfaces to remove contaminants

- Etching or activating surfaces to enhance adhesion

2. Oxidizing Process

Applying chemical solutions or electrolytic processes to create a controlled oxide layer on the metal surface, resulting in the desired color and finish.

- Selecting and applying appropriate chemical solutions

- Monitoring and controlling oxidation process parameters such as temperature, pH, and time

3. Finishing and Quality Control

Post-treatment processes to enhance the finish and ensure quality, including rinsing, drying, and sealing. Conducting inspections to verify adherence to specifications.

- Rinsing and drying treated surfaces

- Applying protective coatings or sealants

- Inspecting finished products for quality and adherence to standards

4. Equipment Maintenance

Maintaining and calibrating equipment used in the oxidation process to ensure optimal performance and safety. Troubleshooting and resolving technical issues.

- Cleaning and maintaining plating tanks, pumps, and other equipment

- Monitoring and adjusting solution concentrations and pH levels

- Troubleshooting and resolving equipment malfunctions

Interview Tips

To ace an interview for an Oxidized Finish Plater position, candidates should prepare thoroughly and showcase their knowledge, skills, and experience relevant to the role.

1. Research the Company and Position

Familiarize yourself with the company’s background, values, and products or services. This demonstrates your interest in the opportunity and helps you align your responses with the company’s culture and goals.

- Visit the company’s website and social media pages

- Read industry news and articles related to the company and the plating industry

2. Highlight Relevant Experience and Skills

Emphasize your experience in surface preparation, oxidation processes, and quality control. Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Describe specific projects where you successfully applied chemical or electrolytic oxidation techniques

- Provide examples of how you have improved processes or resolved technical challenges

3. Demonstrate Knowledge of Equipment and Safety

Show that you are familiar with the equipment used in the oxidation process and that you understand the importance of safety protocols. Discuss your experience with troubleshooting and maintaining equipment.

- List the types of equipment you have experience operating, such as plating tanks, pumps, and controllers

- Describe your understanding of safety procedures in the plating industry

4. Prepare for Technical Questions

Be prepared to answer questions about the chemistry and processes involved in oxidized finishing. Review basic chemistry concepts, such as pH levels and oxidation-reduction reactions.

- Study the different types of chemical solutions used in oxidation processes

- Practice explaining the principles of electrolytic oxidation

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Oxidized Finish Plater role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.