Are you gearing up for an interview for a Plating Technician position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Plating Technician and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

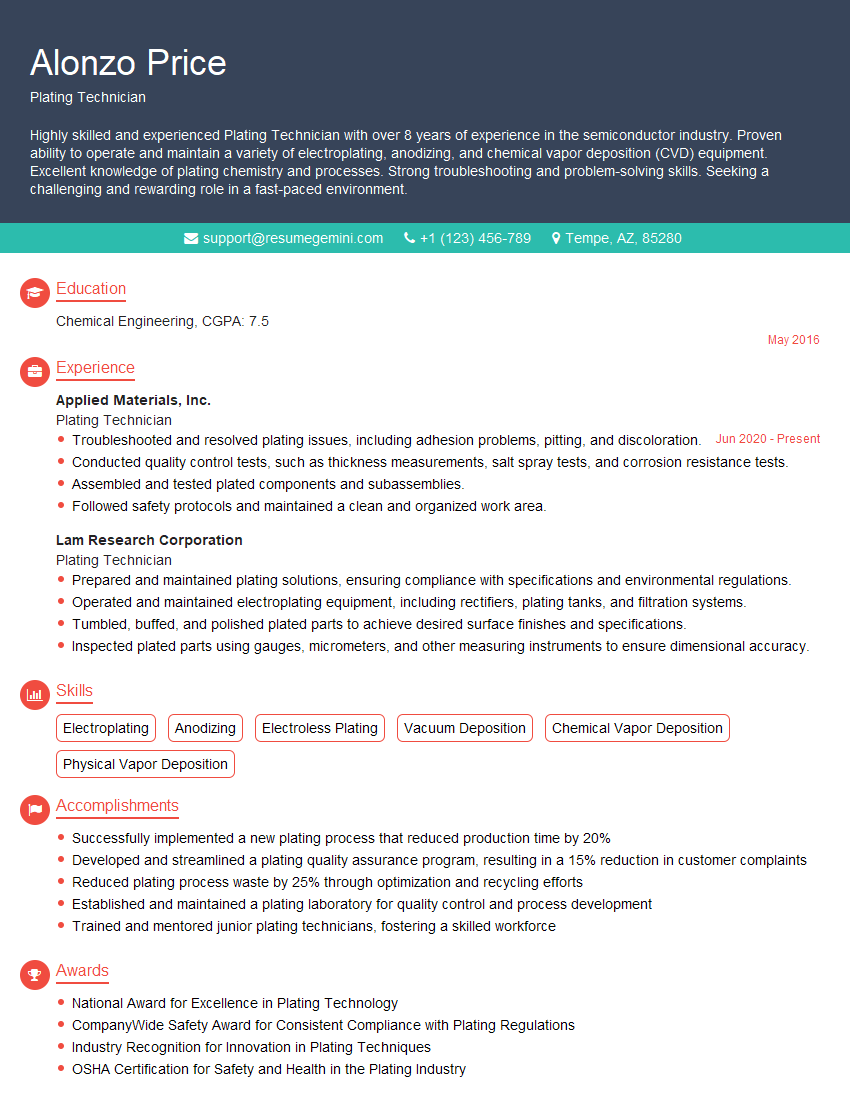

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plating Technician

1. Describe the key steps involved in the electroplating process?

The electroplating process consists of several key steps to achieve the desired coating on a substrate:

- Surface Preparation: The substrate is cleaned and prepared to remove any contaminants and ensure proper adhesion of the coating.

- Masking: Non-targeted areas of the substrate are masked to prevent plating in those regions.

- Electrocleaning: The substrate is immersed in an alkaline solution and subjected to an electric current to remove any remaining impurities.

- Stripping (optional): If necessary, the substrate is subjected to a stripping solution to remove any existing coatings or oxides.

- Plating: The substrate is immersed in a plating solution containing metal ions. An electric current is passed through the solution, causing the metal ions to deposit on the substrate’s surface.

- Post-Treatment: After plating, the substrate may undergo additional treatments such as heat treatment, polishing, or passivation to enhance the coating’s properties.

2. Explain the different types of electroplating baths?

Acidic Baths

- Used for plating metals such as copper, nickel, zinc, and chromium.

- Provide bright and corrosion-resistant coatings.

Alkaline Baths

- Used for plating metals such as silver, gold, and tin.

- Provide good adhesion and smooth coatings.

Neutral Baths

- Used for plating metals such as zinc-nickel alloys.

- Offer a combination of properties from both acidic and alkaline baths.

3. What is the purpose of the Hull Cell test?

The Hull Cell test is used to evaluate the quality and uniformity of an electroplating bath. It provides information about the bath’s throwing power, current distribution, and the presence of impurities:

- Throwing Power: Assesses the bath’s ability to deposit metal evenly on complex or recessed surfaces.

- Current Distribution: Indicates the distribution of current density across the surface of the substrate.

- Impurities Detection: Helps identify any contaminants or impurities that may affect the plating process.

4. What factors influence the thickness of an electroplated coating?

- Current Density: Higher current density generally results in thicker coatings.

- Plating Time: Longer plating times allow for more metal deposition.

- Concentration of Plating Solution: Higher metal ion concentration in the solution promotes thicker coatings.

- Temperature: Optimal bath temperature can enhance coating thickness.

- Agitation: Proper agitation ensures uniform deposition and prevents uneven coating buildup.

5. Describe the techniques used to control the porosity of electroplated coatings?

- Pulse Plating: Alternating current pulses can reduce porosity by producing finer-grained deposits.

- Alloy Plating: Adding a secondary metal to the plating bath can decrease porosity by filling micro-voids.

- Post-Treatment: Heat treatment or chemical treatments can help seal pores and increase coating density.

6. What are the common defects associated with electroplating, and how can they be prevented or corrected?

- Pitting: Caused by impurities or insufficient cleaning. Prevention: Proper surface preparation and filtration of plating solutions.

- Blistering: Occurs due to trapped gases or hydrogen embrittlement. Prevention: Proper degassing of solutions and heat treatment.

- Peeling: Inadequate adhesion between the coating and substrate. Prevention: Effective surface preparation, proper plating parameters.

- Burning: Caused by excessive current density. Prevention: Optimize current density based on Hull Cell test results.

7. Explain the role of anodes in the electroplating process?

Anodes play crucial roles in electroplating:

- Metal Dissolution: Anodes provide the metal ions that are deposited on the substrate during the plating process.

- Current Distribution: The shape and size of anodes influence the distribution of current density in the plating bath.

- Anode Polarization: Anodes undergo electrochemical reactions that affect the efficiency and quality of the plating process.

8. What are the different methods for measuring the thickness of electroplated coatings?

- Magnetic Thickness Gauge: Non-destructive method using magnetic principles to measure coatings on ferrous substrates.

- Eddy Current Gauge: Non-destructive method suitable for non-ferrous and thin coatings.

- Micrometer or Calipers: For measuring the difference in thickness before and after plating.

- Cross-Section Analysis: Destructive method involving cutting and examining a sample under a microscope.

9. What is the importance of maintaining proper pH levels in electroplating baths?

pH levels significantly impact electroplating processes:

- Coating Quality: Optimal pH ensures the formation of uniform and adherent coatings.

- Metal Ion Solubility: pH influences the solubility of metal ions in the plating solution.

- Anodic Dissolution: pH affects the rate of anode dissolution and the release of metal ions.

- Bath Stability: Maintaining proper pH helps prevent the precipitation of metal hydroxides and other compounds.

10. Explain the safety precautions that must be observed when working with electroplating chemicals?

- Wear Personal Protective Equipment (PPE): Gloves, goggles, apron, and proper clothing to protect against chemical exposure.

- Ventilation: Ensure adequate ventilation to prevent inhalation of harmful fumes.

- Proper Handling and Storage: Handle chemicals safely and follow manufacturer’s instructions for storage.

- Waste Disposal: Dispose of spent solutions and waste materials according to environmental regulations.

- Emergency Response Plan: Establish an emergency response plan for spills, leaks, or accidents.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plating Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plating Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Plating Technician is accountable for operating and maintaining electroplating equipment to deposit a thin layer of metal onto a surface. They ensure that the plating process meets quality standards and environmental regulations.

1. Equipment Operation and Maintenance

Operate and maintain electroplating equipment, including preparation tanks, plating tanks, and drying ovens.

- Monitor and adjust plating parameters, such as temperature, pH, and current density.

- Troubleshoot and repair equipment malfunctions.

- Perform routine maintenance, such as cleaning and lubricating.

2. Plating Process

Prepare surfaces for plating, including cleaning, degreasing, and etching.

- Load and unload parts into and from plating tanks.

- Control plating thickness and quality.

- Follow plating procedures and recipes.

3. Quality Control

Inspect plated parts to ensure they meet specifications.

- Perform quality control tests, such as thickness measurements and corrosion resistance tests.

- Identify and correct defects.

- Maintain quality records.

4. Environmental Compliance

Follow environmental regulations and dispose of plating chemicals properly.

- Monitor and control wastewater discharge.

- Handle and store hazardous materials safely.

Interview Tips

Preparing for an interview can help you make a good impression and increase your chances of success. Here are some tips for acing a Plating Technician interview:

1. Research the Company and Industry

Research the company you’re applying to and the plating industry as a whole. This will help you understand the company’s culture and the industry’s trends.

2. Practice Your Answers

Practice answering common interview questions, such as “Tell me about yourself” and “Why are you interested in this job?”

- Consider using the STAR method to structure your answers.

- Situation: Briefly describe a relevant situation or task.

- Task: Explain the task or challenge you faced.

- Action: Describe the specific actions you took to address the challenge.

- Result: Quantify the results of your actions and highlight the impact you had.

3. Highlight Your Skills and Experience

Make sure to highlight your skills and experience that are relevant to the job you’re applying for. For example, if you have experience with a particular type of plating equipment, be sure to mention it.

4. Be Prepared to Talk About Your Safety Knowledge

Plating technicians must follow safety protocols to protect themselves and others. Be prepared to discuss your knowledge of safety regulations and how you ensure safety in the workplace.

5. Ask Questions

At the end of the interview, you’ll likely have an opportunity to ask questions. This is a good time to ask about the company’s culture, the job responsibilities, and the training opportunities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plating Technician interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.