Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Vacuum Applicator Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

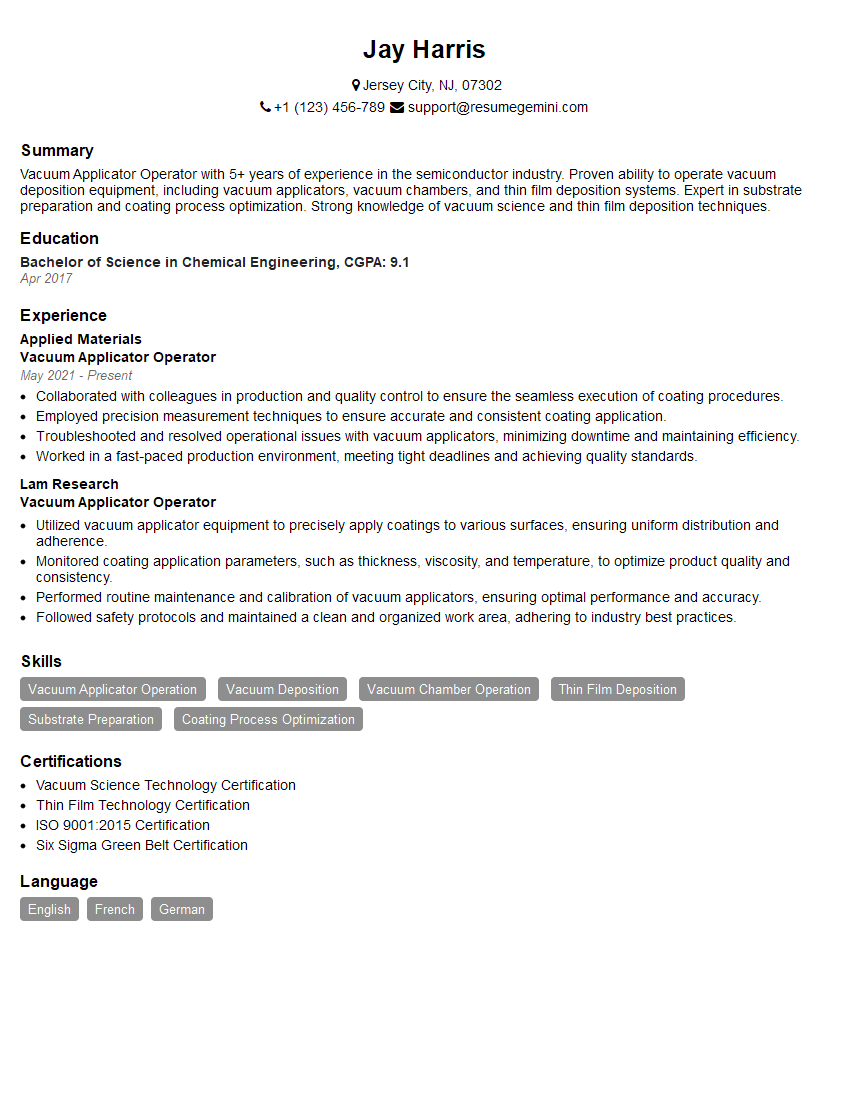

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Vacuum Applicator Operator

1. Describe the process of vacuum application in detail?

The vacuum application process involves several steps:

- Surface preparation: The surface to be coated is cleaned and prepared to ensure proper adhesion.

- Vacuum chamber setup: The vacuum chamber is sealed, and the vacuum pump is activated to create a vacuum environment.

- Material placement: The material to be coated is placed inside the vacuum chamber.

- Deposition: The coating material is vaporized and deposited onto the substrate surface under vacuum conditions.

- Cooling and degassing: After deposition, the coated substrate is cooled, and any residual gases are removed to enhance coating stability.

- Venting: Finally, the vacuum chamber is vented to atmospheric pressure, allowing the coated substrate to be removed.

2. What are the different techniques used in vacuum application?

Physical vapor deposition (PVD)

- Sputtering

- Evaporation

Chemical vapor deposition (CVD)

- Plasma enhanced CVD (PECVD)

- Metal organic CVD (MOCVD)

3. Can you explain the principle of magnetron sputtering?

Magnetron sputtering is a PVD technique that utilizes a magnetic field to enhance ionization of the sputtered material.

- A magnetic field is applied parallel to the target surface.

- Electrons in the plasma are trapped in the magnetic field lines.

- Trapped electrons collide with gas atoms, ionizing them.

- The ionized gas atoms bombard the target material, causing atoms to be sputtered.

- The sputtered atoms deposit on the substrate surface.

4. What are the factors that affect the thickness and quality of a vacuum coating?

- Deposition rate

- Substrate temperature

- Vacuum pressure

- Target material properties

- Distance between target and substrate

5. How do you maintain and troubleshoot a vacuum deposition system?

- Maintenance

- Regular cleaning and inspection

- Preventive maintenance

- Troubleshooting

- Identifying and resolving vacuum leaks

- Addressing contamination issues

- Calibrating and adjusting system parameters

6. Describe the safety precautions that must be observed when working with vacuum equipment?

- Wear appropriate personal protective equipment (PPE).

- Ensure proper ventilation to prevent inhalation of toxic fumes.

- Handle and store chemicals safely.

- Be aware of electrical hazards.

- Follow established safety protocols and procedures.

7. What is the role of a vacuum applicator operator in a production environment?

- Operating and monitoring vacuum deposition equipment.

- Performing quality control checks on coated products.

- Maintaining and troubleshooting vacuum systems.

- Adhering to safety protocols and procedures.

- Working as part of a production team to meet production targets.

8. How do you ensure the quality of vacuum-coated products?

- Visual inspection: Checking for defects, such as scratches, pinholes, or uneven coating.

- Thickness measurement: Using instruments like profilometers or ellipsometers to measure coating thickness.

- Adhesion testing: Performing tests like the scratch test or tape test to assess coating adhesion.

- Functionality testing: Evaluating the performance of the coating in its intended application.

9. What are the common problems encountered in vacuum application and how do you resolve them?

- Vacuum leaks: Use a leak detector to locate and seal leaks.

- Contamination: Clean the vacuum chamber and components thoroughly.

- Poor coating adhesion: Optimize deposition parameters, such as substrate temperature or deposition rate.

- Coating defects: Identify the cause of defects, such as dust particles or improper vacuum conditions, and take corrective actions.

10. How do you stay up-to-date with the latest advancements in vacuum application technology?

- Attending industry conferences and workshops.

- Reading technical journals and research papers.

- Participating in online forums and discussions.

- Seeking training and certification from equipment manufacturers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Vacuum Applicator Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Vacuum Applicator Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Vacuum Applicator Operator, you are accountable for the operation and maintenance of vacuum applicators in a production environment. Your key responsibilities include:

1. Machine Operation

intro paragraph

- Set up and operate vacuum applicators according to established procedures.

- Monitor machine performance and make necessary adjustments to ensure optimal operation.

2. Material Handling

intro paragraph

- Load and unload materials from the vacuum applicator.

- Ensure proper alignment and positioning of materials for accurate application.

3. Quality Control

intro paragraph

- Inspect finished products for defects and non-conformances.

- Identify and report any quality issues promptly.

4. Maintenance and Troubleshooting

intro paragraph

- Perform routine maintenance and cleaning of vacuum applicators to ensure proper functioning.

- Identify and troubleshoot common machine issues, and perform basic repairs as necessary.

Interview Tips

To help you ace the Vacuum Applicator Operator interview, here are some tips:

1. Research the Company and Role

intro paragraph

- Visit the company’s website to learn about their products, services, and culture.

- Review the job description carefully to understand the specific requirements of the role.

2. Highlight Your Experience and Skills

intro paragraph

- Quantify your accomplishments and use specific examples to demonstrate your abilities.

- Tailor your resume and cover letter to the specific responsibilities of the Vacuum Applicator Operator role.

3. Practice Answering Common Interview Questions

intro paragraph

- Prepare for questions about your experience, skills, and knowledge of vacuum applicators.

- Rehearse your answers to common behavioral interview questions, such as “Tell me about a time when you had to overcome a challenge.”.

4. Be Prepared to Discuss Safety Procedures

intro paragraph

- Vacuum applicators can pose safety hazards, so be prepared to discuss your understanding of and adherence to safety protocols.

- Provide examples of how you have implemented safety measures in previous roles.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Vacuum Applicator Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.