Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Welding Rod Coater position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

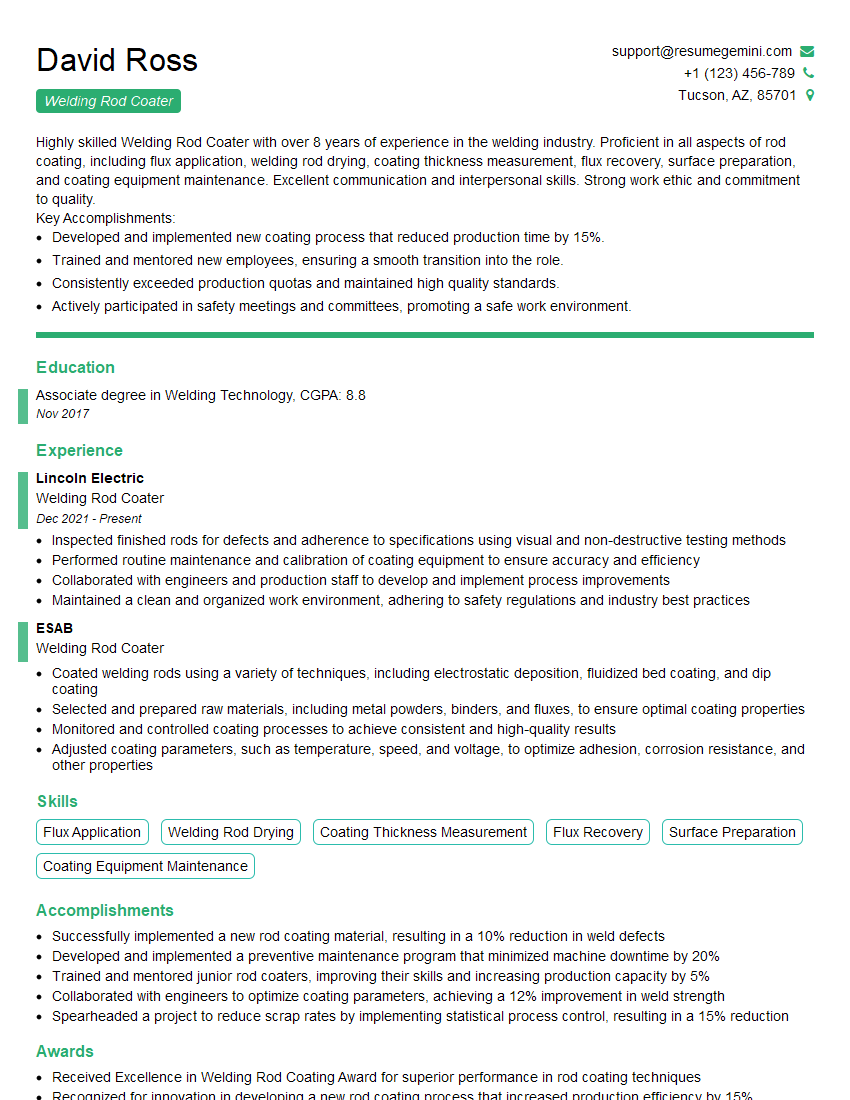

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Welding Rod Coater

1. Explain the process of preparing the welding rod for coating?

The process of preparing the welding rod for coating involves several steps to ensure proper adhesion and performance of the coating material:

- Cleaning: The welding rod is cleaned to remove any contaminants, such as rust, oil, or dirt, that could interfere with the coating process.

- Annealing: The welding rod is heated to a specific temperature and then cooled slowly, which softens the metal and makes it more ductile for coating.

- Drawing: The welding rod is drawn through a die to reduce its diameter and achieve the desired thickness for the coating.

- Fluxing: A flux is applied to the welding rod, which helps to remove oxides and impurities from the metal surface during welding.

2. What are the different types of coating materials used in welding rods?

There are various types of coating materials used in welding rods to enhance their performance and cater to different welding applications:

Types of Coating Materials

- Cellulosic: Provides high arc stability and penetration, suitable for welding in all positions.

- Rutile: Offers easy slag removal and a smooth weld bead, commonly used for general-purpose welding.

- Basic: Produces a thick slag layer, which protects the weld pool from contamination and is often used for high-strength welding.

- Acidic: Generates minimal slag, making it suitable for welding thin metals or where slag removal is critical.

- Metal Powder: Contains metal powders in the coating, which improve deposition rates and reduce spatters.

3. Describe the dipping method used in coating welding rods?

The dipping method is a manual process used to apply coating materials onto welding rods:

- The prepared welding rod is immersed into a molten coating material, such as a flux or a mixture of fluxes and other additives.

- The rod is withdrawn from the molten bath, and the excess coating material is allowed to drain off.

- The coated rod is then cooled, which solidifies the coating and ensures its adherence to the rod.

- This process can be repeated multiple times to achieve the desired coating thickness.

4. Explain the importance of controlling the thickness of the coating on the welding rod?

Controlling the thickness of the coating on the welding rod is crucial for several reasons:

- Weld Quality: The coating thickness affects the stability of the arc, penetration depth, and the amount of slag produced during welding, thus influencing the quality of the weld.

- Welding Efficiency: A proper coating thickness ensures efficient metal transfer, minimizes spatter, and optimizes welding deposition rates.

- Weld Bead Appearance: The coating thickness influences the shape and smoothness of the weld bead, which is important for aesthetic and functional requirements.

- Compliance with Standards: Industry standards and specifications often specify the required coating thickness range for different types of welding rods.

5. What are the different techniques used to apply coating to welding rods?

There are several techniques used to apply coating to welding rods, including:

- Dipping: Manually immersing the rod into a molten coating bath.

- Extrusion: Forcing the coating material through a die to form a continuous coating on the rod.

- Electrostatic Spraying: Using electrostatic forces to attract the coating particles onto the rod.

- Plasma Spraying: Utilizing a plasma torch to melt and spray the coating material onto the rod.

- Powder Adhesion: Applying a powdered coating material and then heating it to fuse it to the rod’s surface.

6. How do you ensure the quality of the coated welding rods?

Ensuring the quality of the coated welding rods involves several steps:

- Raw Material Inspection: Verifying the quality of the welding rods and the coating materials used.

- Coating Process Control: Monitoring and controlling the coating parameters, such as temperature, thickness, and adhesion.

- Visual Inspection: Examining the coated rods for any defects or inconsistencies.

- Mechanical Testing: Performing tests to assess the mechanical properties of the coated rods, such as tensile strength and ductility.

- Weldability Testing: Conducting welding tests to evaluate the performance of the coated rods in actual welding conditions.

7. What are the common defects that can occur during the coating process?

Several defects can occur during the coating process of welding rods, including:

- Inconsistent Coating Thickness: Variations in the coating thickness can affect weld quality and performance.

- Flaking or Peeling: The coating may detach from the rod’s surface due to poor adhesion.

- Cracking: The coating may develop cracks due to thermal stresses or improper drying.

- Porosity: Air bubbles or voids may become trapped in the coating, weakening its integrity.

- Slag Inclusions: Impurities or slag particles may get embedded in the coating, affecting weld quality.

8. What safety precautions should be taken when working with welding rod coating materials?

Working with welding rod coating materials requires adherence to safety precautions:

- Respiratory Protection: Wear a respirator to prevent inhalation of fumes and particles.

- Skin Protection: Use gloves and protective clothing to avoid skin contact with coating materials.

- Eye Protection: Wear safety glasses or a face shield to protect eyes from splashes and sparks.

- Ventilation: Ensure adequate ventilation in the workspace to remove harmful fumes.

- Proper Handling and Storage: Handle and store coating materials safely according to manufacturer’s instructions.

9. How do you stay updated on the latest advancements in welding rod coating technology?

To stay updated on the latest advancements in welding rod coating technology:

- Industry Publications and Journals: Access technical publications and industry journals.

- Conferences and Trade Shows: Attend industry events to learn about new technologies and products.

- Vendor Training: Participate in training programs offered by welding rod coating manufacturers.

- Online Resources: Utilize online platforms to research and connect with industry experts.

- Networking: Connect with other professionals in the field to exchange knowledge and insights.

10. Why are you interested in this Welding Rod Coater position?

I am eager to contribute my skills and experience as a Welding Rod Coater to your esteemed organization. My passion for welding and my proven expertise in coating techniques make me a suitable candidate for this role. I am confident that I can leverage my knowledge to optimize the coating process, ensure product quality, and support the production goals of the company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Welding Rod Coater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Welding Rod Coater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Welding Rod Coaters play a crucial role in ensuring the quality and efficiency of welding processes. Their primary responsibilities include:

Coating Welding Rods

Coaters prepare welding rods by applying a uniform layer of coating material to their surfaces. This coating enhances the rods’ performance during welding by stabilizing the arc, shielding the weld pool from contaminants, and improving weld quality.

Maintaining Coating Equipment

Coaters are responsible for the proper maintenance and calibration of coating equipment. This includes cleaning and inspecting machinery, replacing worn parts, and ensuring that all equipment operates efficiently.

Monitoring Production Processes

Coaters closely monitor the coating process to ensure that rods meet the required specifications. They inspect coated rods for defects, adjust coating parameters as needed, and keep records of production data.

Troubleshooting Production Issues

In the event of any production issues, coaters troubleshoot problems and identify the source of defects. They implement corrective actions to resolve issues promptly and maintain production efficiency.

Interview Tips

To ace the interview for a Welding Rod Coater position, candidates should prepare in the following ways:

1. Research the Company and Role

Thoroughly research the company’s history, products, and industry presence. Understand the specific requirements of the Welding Rod Coater role within the organization.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in welding rod coating, including your knowledge of coating materials, equipment operation, and troubleshooting techniques. Highlight your experience in maintaining and repairing coating equipment.

3. Prepare for Technical Questions

Expect questions on welding rod coating processes, equipment maintenance, and quality control procedures. Be prepared to discuss specific examples of your work and how you have handled challenging situations.

4. Showcase Your Problem-Solving Abilities

Demonstrate your problem-solving skills by providing examples of how you have identified and resolved issues in previous roles. Highlight your ability to analyze data, make informed decisions, and take corrective actions effectively.

5. Be Enthusiastic and Motivated

Convey your enthusiasm for the welding industry and your eagerness to contribute to the company’s success. Show your commitment to quality and safety in all aspects of your work.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Welding Rod Coater interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!