Are you gearing up for a career in Cutting Tool Sharpener? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Cutting Tool Sharpener and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

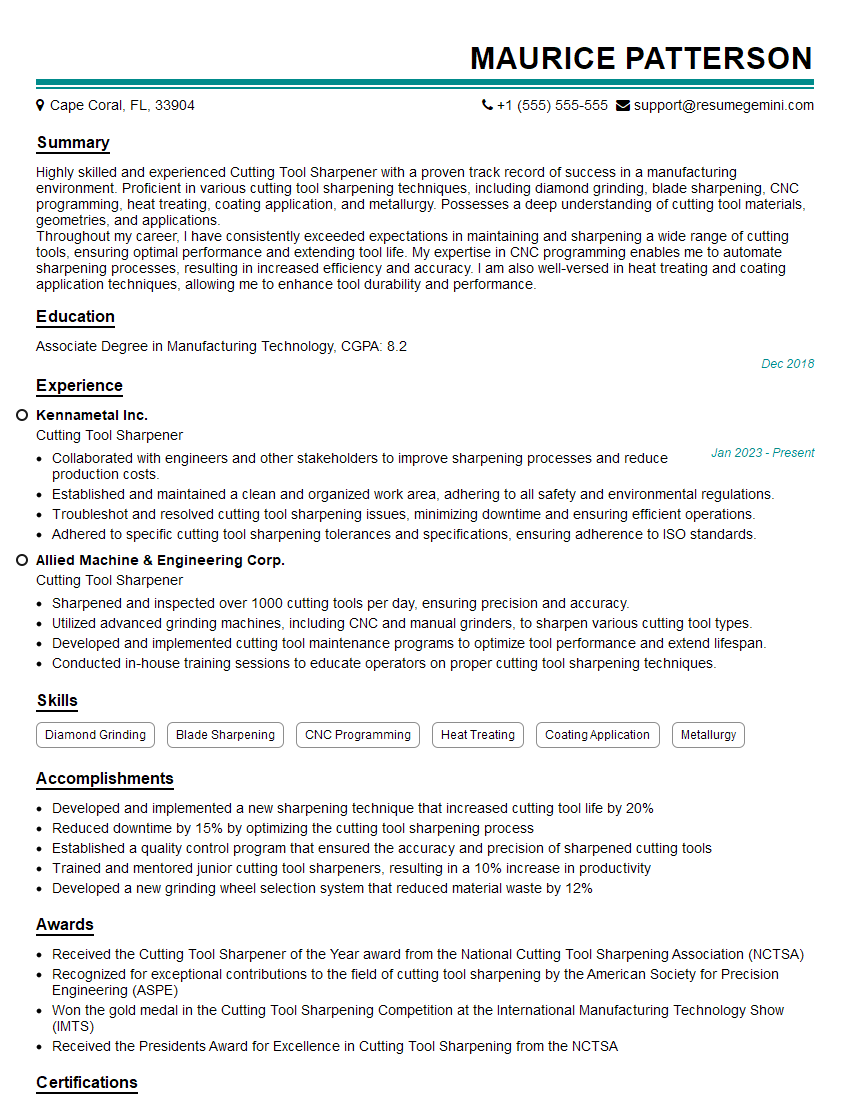

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cutting Tool Sharpener

1. Explain the different types of cutting tools and their applications?

There are a wide variety of cutting tools available, each with its own specific application. Some of the most common types of cutting tools include:

- Knives: Knives are used for a variety of cutting tasks, including slicing, dicing, and chopping. They are available in a variety of shapes and sizes, depending on the intended use.

- Saws: Saws are used for cutting through wood, metal, and other materials. They are available in a variety of types, including hand saws, power saws, and table saws.

- Drills: Drills are used for creating holes in wood, metal, and other materials. They are available in a variety of sizes and types, depending on the intended use.

- Grinders: Grinders are used for shaping and smoothing metal and other materials. They are available in a variety of sizes and types, depending on the intended use.

- Sharpeners: Sharpeners are used for sharpening knives, saws, and other cutting tools. They are available in a variety of sizes and types, depending on the intended use.

2. What are the different types of abrasives and their applications?

- Natural abrasives: These abrasives are found in nature and include materials such as sandstone, pumice, and garnet. They are typically used for grinding and polishing.

- Manufactured abrasives: These abrasives are created in a laboratory and include materials such as aluminum oxide, silicon carbide, and diamond. They are typically used for grinding, polishing, and cutting.

- Bonded abrasives: These abrasives are made by bonding abrasive particles to a backing material. They are typically used for grinding and polishing.

- Coated abrasives: These abrasives are made by coating abrasive particles onto a backing material. They are typically used for sanding and finishing.

3. What are the different types of sharpening machines and their applications?

- Grinding machines: These machines use abrasive wheels to grind and shape metal and other materials. They are typically used for heavy-duty sharpening tasks.

- Polishing machines: These machines use abrasive wheels or brushes to polish metal and other materials. They are typically used for finishing tasks.

- Honing machines: These machines use a fine abrasive stone to hone the edge of a cutting tool. They are typically used for sharpening knives and other cutting tools.

- Sharpening stones: These stones are used to sharpen knives and other cutting tools. They are available in a variety of grits, depending on the intended use.

4. What are the different factors to consider when selecting a sharpening machine?

- The type of material to be sharpened: Different materials require different types of abrasives.

- The desired finish: The type of finish required will determine the grit of the abrasive to be used.

- The speed and efficiency required: Some machines are faster and more efficient than others.

- The cost: The cost of the machine will need to be considered.

5. What are the different safety precautions to take when operating a sharpening machine?

- Wear eye protection: Abrasive particles can fly off the machine and cause eye injuries.

- Wear gloves: Gloves will protect your hands from cuts and abrasions.

- Keep the machine clean: A clean machine is less likely to cause accidents.

- Follow the manufacturer’s instructions: The manufacturer’s instructions will provide specific safety precautions for the machine.

6. What are the different types of cutting tool materials and their properties?

- High-carbon steel: This steel is hard and durable, but it is also brittle.

- Alloy steel: This steel is harder and more durable than high-carbon steel, but it is also more expensive.

- Stainless steel: This steel is corrosion-resistant and easy to clean, but it is not as hard or durable as high-carbon steel or alloy steel.

- Ceramic: This material is very hard and durable, but it is also brittle.

- Carbide: This material is very hard and durable, but it is also expensive.

7. What are the different factors to consider when selecting a cutting tool material?

- The type of material to be cut: Different materials require different types of cutting tools.

- The desired finish: The type of finish required will determine the type of cutting tool to be used.

- The cost: The cost of the cutting tool will need to be considered.

8. What are the different types of cutting tool geometries?

- Single-point cutting tools: These tools have a single cutting edge that is used to cut the material.

- Multi-point cutting tools: These tools have multiple cutting edges that are used to cut the material.

- Continuous cutting tools: These tools have a continuous cutting edge that is used to cut the material.

9. What are the different factors to consider when selecting a cutting tool geometry?

- The type of material to be cut: Different materials require different types of cutting tool geometries.

- The desired finish: The type of finish required will determine the type of cutting tool geometry to be used.

- The cost: The cost of the cutting tool will need to be considered.

10. What are the different types of cutting tool coatings?

- TiN: This coating is hard and wear-resistant.

- TiCN: This coating is harder and more wear-resistant than TiN.

- TiAlN: This coating is even harder and more wear-resistant than TiCN.

- DLC: This coating is a diamond-like carbon coating that is very hard and wear-resistant.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cutting Tool Sharpener.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cutting Tool Sharpener‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cutting Tool Sharpeners play a critical role in manufacturing and industrial settings by maintaining and sharpening cutting tools to ensure optimal performance and precision.

1. Sharpening and Maintaining Cutting Tools

Sharpening a wide range of cutting tools, including drill bits, milling cutters, taps, and dies, using various sharpening equipment.

- Selecting and using the appropriate abrasives and techniques to achieve the desired sharpness and accuracy.

- Inspecting and testing sharpened tools to ensure they meet specifications and quality standards.

2. Tool Inspection and Quality Control

Inspecting and measuring cutting tools using precision instruments to assess their condition, wear, and damage.

- Identifying and repairing minor defects, such as nicks and burrs, to extend the life of the tools.

- Collaborating with engineers and technicians to determine the optimal sharpening parameters for specific applications.

3. Equipment Maintenance and Calibration

Maintaining and calibrating sharpening equipment to ensure accuracy and precision.

- Performing regular preventive maintenance, cleaning, and lubrication of equipment.

- Calibrating machines and instruments to meet industry standards.

4. Safety and Compliance

Adhering to all safety regulations and protocols in the sharpening area.

- Using appropriate personal protective equipment (PPE), such as gloves, eye protection, and respirators.

- Maintaining a clean and organized work environment.

Interview Tips

Preparing for a Cutting Tool Sharpener interview requires understanding the key job responsibilities and aligning your skills and experience accordingly. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, research the company’s industry, products, and values. This will demonstrate your interest and help you understand their specific requirements.

- Review the job description thoroughly and identify the essential skills and qualifications they are seeking.

- Visit the company’s website and LinkedIn page to learn about their culture and recent developments.

2. Highlight Your Skills and Experience

Showcase your technical proficiency in sharpening cutting tools using different equipment and techniques.

- Quantify your accomplishments by providing specific examples of how you have improved tool performance or reduced downtime.

- Emphasize your attention to detail, precision, and ability to meet tight tolerances.

3. Demonstrate Your Knowledge of Safety and Compliance

Highlight your understanding of safety protocols and your commitment to maintaining a safe work environment.

- Discuss your experience with OSHA or ISO safety standards and how you have implemented them in previous roles.

- Explain your familiarity with the proper handling and storage of hazardous materials, such as abrasives and coolants.

4. Ask Thoughtful Questions

Asking relevant and insightful questions demonstrates your engagement and interest in the role and the company.

- Inquire about the company’s plans for expanding or improving their sharpening operations.

- Ask about the latest advancements in cutting tool technology and how they are incorporated into the company’s processes.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cutting Tool Sharpener role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.