Are you gearing up for a career in Die Fitter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Die Fitter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

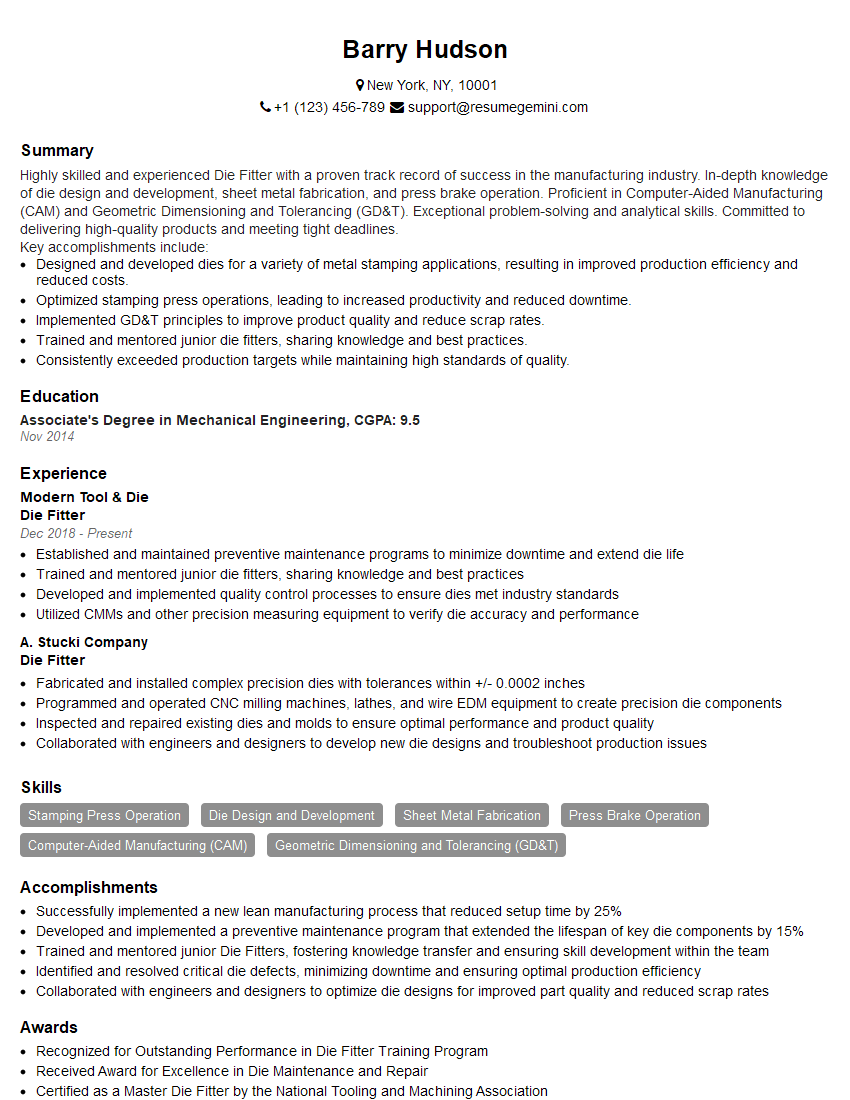

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Die Fitter

1. Explain the process of designing and manufacturing a stamping die.

- Understand the part design and specifications.

- Select the appropriate die type and materials.

- Design the die components, including the punch, die block, stripper, and pressure pad.

- Machine and assemble the die components.

- Test the die to ensure it meets the required specifications.

2. What are the different types of stamping dies and when would you use each type?

Progressive dies

- Used for producing high-volume parts.

- Multiple stations perform different operations on the strip material in a single stroke of the press.

Compound dies

- Used for producing complex parts.

- Multiple punches and dies operate simultaneously to create the part.

Transfer dies

- Used for producing parts that require multiple operations.

- The strip material is transferred from one station to another using a transfer mechanism.

3. What are the critical dimensions to consider when designing a stamping die?

- Part thickness

- Part width

- Part length

- Hole size and location

- Bend radii

4. What are the common materials used for stamping dies?

- Tool steel

- Carbide

- Ceramics

- Polycrystalline diamond (PCD)

5. What are the different types of press brakes used in stamping?

- Mechanical press brakes

- Hydraulic press brakes

- Pneumatic press brakes

6. What are the safety precautions that should be taken when operating a press brake?

- Wear appropriate safety gear, including safety glasses, gloves, and hearing protection.

- Inspect the press brake and tooling before each use.

- Keep hands and fingers clear of the bending area.

- Never operate the press brake while under the influence of drugs or alcohol.

7. What are the different types of stamping defects and how can they be prevented?

- Cracking

- Tearing

- Wrinkling

- Burring

8. What are the different types of stamping lubricants and how are they applied?

- Oil-based lubricants

- Water-based lubricants

- Solid lubricants

9. What are the different types of stamping presses and how do they differ?

- Mechanical presses

- Hydraulic presses

- Pneumatic presses

10. What are the different types of stamping dies and how are they used?

- Progressive dies

- Compound dies

- Transfer dies

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Die Fitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Die Fitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Die fitters are responsible for installing, maintaining, and repairing dies and other equipment used in metalworking and manufacturing processes. They work closely with engineers and technicians to ensure that the dies are properly designed and installed, and that the equipment is operating correctly.

1. Die Installation

Die fitters install dies into presses and other equipment. They ensure that the dies are properly aligned and secured, and that the equipment is operating correctly.

- Install dies into presses and other equipment

- Ensure that the dies are properly aligned and secured

- Ensure that the equipment is operating correctly

2. Die Maintenance

Die fitters maintain dies and other equipment by performing regular inspections and repairs. They also replace worn or damaged parts.

- Perform regular inspections of dies and other equipment

- Repair dies and other equipment as needed

- Replace worn or damaged parts

3. Equipment Troubleshooting

Die fitters troubleshoot equipment problems and make repairs. They also work with engineers and technicians to identify and resolve issues.

- Troubleshoot equipment problems

- Make repairs to equipment as needed

- Work with engineers and technicians to identify and resolve issues

4. Safety

Die fitters work in a hazardous environment, so they must follow all safety procedures. They must also wear appropriate personal protective equipment.

- Follow all safety procedures

- Wear appropriate personal protective equipment

Interview Tips

Preparing well for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for a die fitter position.

1. Research the Company

Before the interview, take some time to research the company. This will show the interviewer that you are interested in the position and that you have taken the time to learn about the company’s culture and values.

- Visit the company’s website

- Read the company’s annual report

- Talk to people who work for the company

2. Practice Your Answers

Once you have researched the company, take some time to practice answering common interview questions. This will help you feel more confident and prepared during the interview.

- Use the STAR method to answer interview questions

- Practice answering questions about your skills, experience, and qualifications

- Prepare questions to ask the interviewer

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire.

- Wear a suit or business casual attire

- Make sure your clothes are clean and pressed

- Accessorize with a tie or scarf

4. Be on Time

Punctuality is important, so be sure to arrive on time for your interview. This shows the interviewer that you are respectful of their time.

- Arrive on time for your interview

- Give yourself plenty of time to get to the interview location

- If you are running late, call the interviewer to let them know

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Die Fitter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.