Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Die Reamer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Die Reamer so you can tailor your answers to impress potential employers.

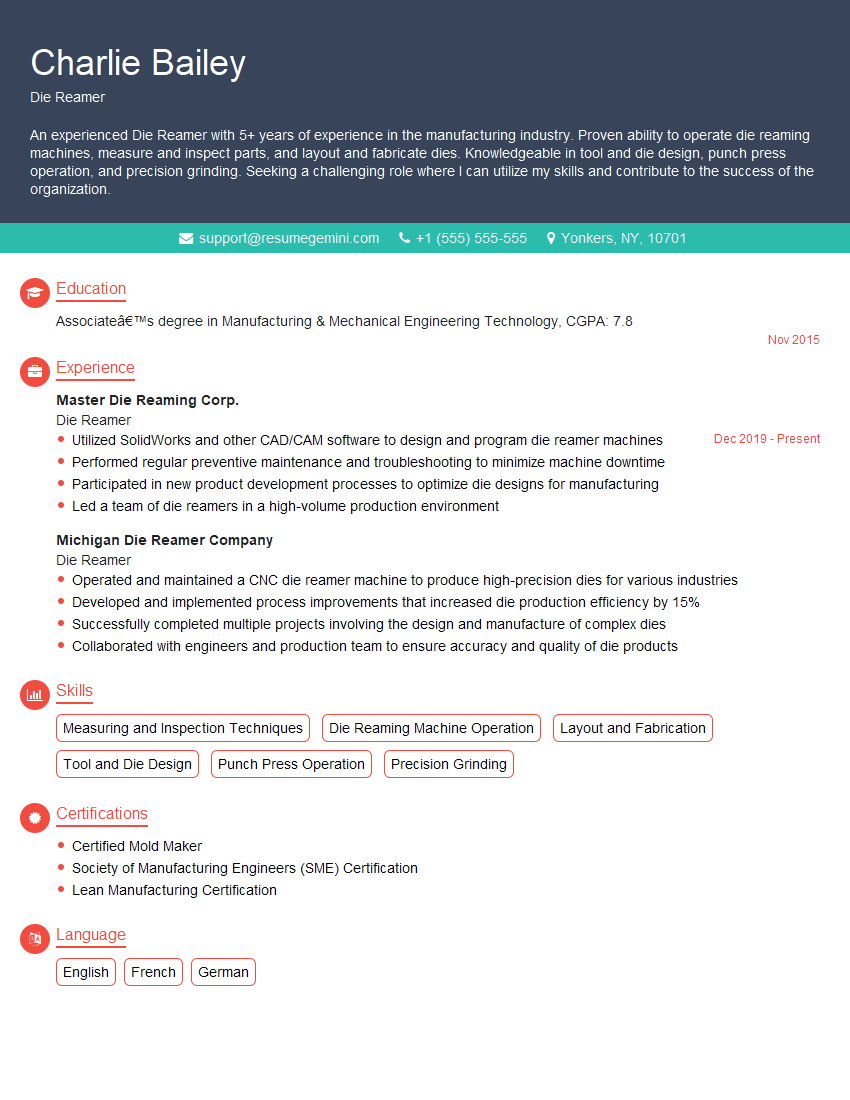

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Die Reamer

1. Explain the different types of reamers and their applications?

- Hand reamers are used for reaming holes by hand.

- Machine reamers are used for reaming holes in a machine.

- Chucking reamers are used for reaming holes in a chuck.

- Boring reamers are used for boring holes.

2. What are the different cutting operations performed by a reamer?

- Enlarging a hole.

- Finishing a hole.

- Producing a smooth surface finish.

- Creating a hole with a specific tolerance.

3. What are the factors that affect the cutting force required for reaming?

- The material of the workpiece.

- The size of the hole.

- The type of reamer.

- The cutting speed.

- The feed rate.

4. What are the different types of reamer materials?

- High-speed steel.

- Carbide.

- Ceramic.

- Diamond.

5. What are the different types of reamer coatings?

- Titanium nitride.

- Titanium carbide.

- Chromium nitride.

- Diamond-like carbon.

6. What are the different types of reamer shanks?

- Straight shank.

- Taper shank.

- Weldon shank.

- CAT shank.

7. What are the different types of reamer flutes?

- Straight flutes.

- Spiral flutes.

- Helical flutes.

8. What are the different types of reamer cutting edges?

- Single cutting edge.

- Double cutting edge.

- Quadruple cutting edge.

9. What are the different types of reamer tolerances?

- H7 tolerance.

- H8 tolerance.

- H9 tolerance.

- H10 tolerance.

10. What are the different types of reamer applications?

- Reaming holes for bolts.

- Reaming holes for dowel pins.

- Reaming holes for bearings.

- Reaming holes for bushings.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Die Reamer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Die Reamer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Die Reamers are responsible for a range of tasks related to the operation and maintenance of die reaming machines. These machines are used to create precision holes in various materials, and Die Reamers must ensure that they are operating correctly and producing high-quality results.

1. Set up and operate die reaming machines

Die Reamers must be able to set up and operate die reaming machines safely and efficiently. They must be able to select the correct tooling for the job and to make adjustments to the machine as needed.

- Inspect and position dies into the machine for reaming operations.

- Mount and secure dies in machines.

- Set machine parameters, such as spindle speed and feed rate.

2. Monitor the operation of die reaming machines

Die Reamers must monitor the operation of die reaming machines closely to ensure that they are operating correctly. They must be able to identify and troubleshoot any problems that may arise.

- Monitor the progress of reaming operations.

- Check the quality of the finished product.

- Identify and resolve problems with the die reaming machine.

3. Maintain die reaming machines

Die Reamers must perform regular maintenance on die reaming machines to ensure that they are in good working order. They must be able to clean and lubricate the machine, and to replace worn or damaged parts.

- Clean and lubricate the die reaming machine.

- Inspect and replace worn or damaged parts.

- Keep records of maintenance performed.

4. Provide support to other operators

Die Reamers may be required to provide support to other operators on the production floor. They may be called upon to train new operators or to help troubleshoot problems with the die reaming machine.

- Train new operators on the die reaming machine.

- Troubleshoot problems with the die reaming machine.

- Provide support to other operators on the production floor.

Interview Tips

Preparing for a Die Reamer interview can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, and it will also give you a better idea of the skills and experience required to be successful in the role.

- Visit the company’s website to learn about their history, mission, and values.

- Read the job description carefully and identify the key skills and experience required.

- If possible, connect with current or former employees of the company on LinkedIn.

2. Practice answering common interview questions

One of the best ways to prepare for your interview is to practice answering common interview questions. This will help you develop clear and concise answers, and it will also boost your confidence.

- Some common interview questions for Die Reamers include:

- Tell me about your experience operating die reaming machines.

- What are your strengths and weaknesses as a Die Reamer?

- How do you stay up-to-date on the latest die reaming technology?

3. Come prepared with questions for the interviewer

Asking thoughtful questions at the end of your interview will show the interviewer that you are engaged and interested in the position. It will also give you a chance to learn more about the company and the role.

- Some good questions to ask include:

- What are some of the biggest challenges facing Die Reamers today?

- What is the company’s culture like?

- What opportunities are there for professional development?

4. Be yourself

The most important tip for acing your interview is to be yourself. Don’t try to be someone you’re not, because the interviewer will be able to tell. Just be confident and authentic, and let your personality shine through.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Die Reamer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!