Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Precision Honer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Precision Honer so you can tailor your answers to impress potential employers.

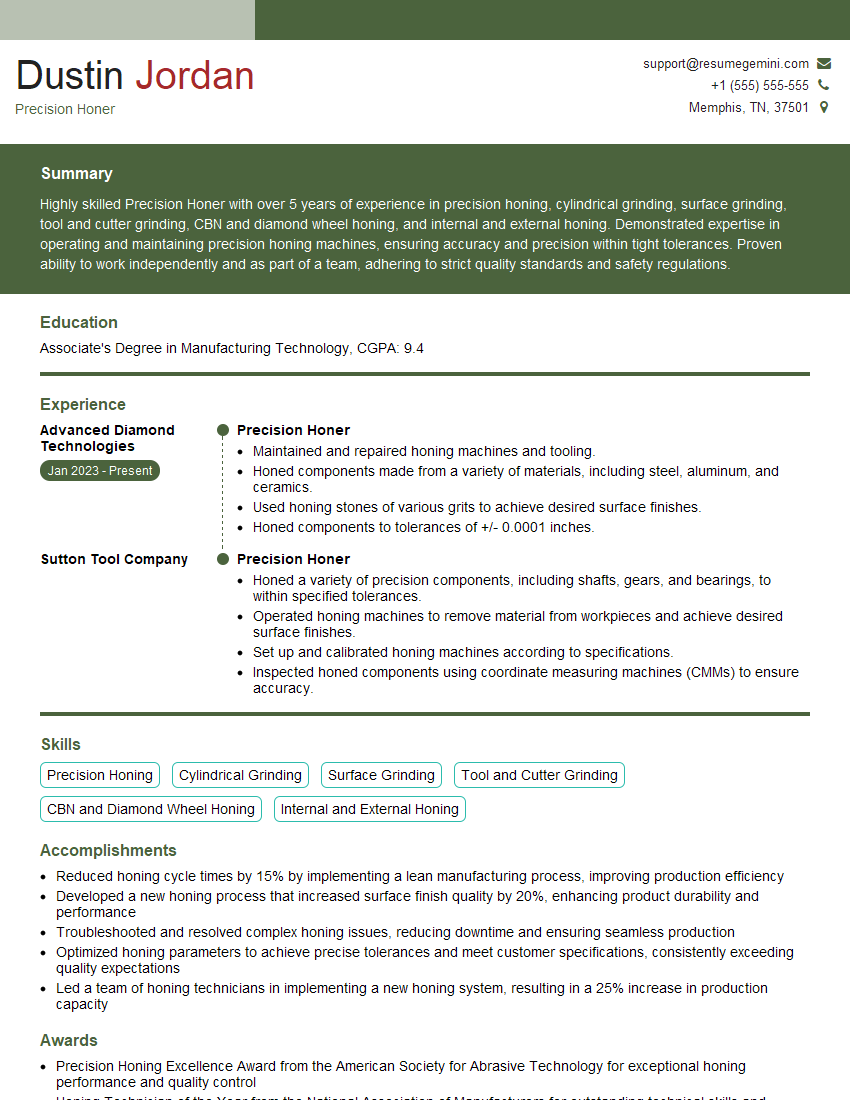

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Precision Honer

1. What are the key responsibilities of a Precision Honer?

A Precision Honer is primarily responsible for performing precision honing operations to achieve specified tolerances and surface finishes on cylindrical components. The duties include:

- Setting up and operating honing machines to hone various types of cylindrical parts according to engineering specifications

- Selecting and installing appropriate tooling and abrasives based on the workpiece material and required finish

- Monitoring honing processes and making adjustments to the machine settings to optimize honing parameters

- Inspecting honed parts for dimensions, surface roughness, and other quality attributes

- Maintaining and calibrating honing equipment to ensure accuracy and precision

2. Explain the different types of honing processes and their applications

Abrasive Honing

- Uses abrasive stones to remove material and create a precise bore diameter and surface finish

- Suitable for processing hard materials such as hardened steel, cast iron, and ceramics

Diamond Honing

- Employs diamond-impregnated honing stones to achieve extremely fine surface finishes and close tolerances

- Used for honing critical components in industries such as aerospace, medical, and automotive

Plateau Honing

- Produces a surface with a specific plateau pattern to enhance bearing performance

- Suitable for honing hydraulic cylinders, engine components, and other parts requiring improved lubrication

3. How do you ensure the accuracy and repeatability of honed parts?

- Rigorously follow established honing processes and procedures

- Use calibrated measuring instruments to verify dimensions and surface finishes

- Monitor critical process parameters such as honing pressure, stroke speed, and honing time

- Implement statistical process control techniques to identify and eliminate sources of variation

- Regularly maintain and calibrate honing equipment to ensure optimal performance

4. How do you handle and resolve honing defects such as taper, bellmouthing, and ovality?

- Analyze the honed parts to identify the type of defect

- Investigate potential causes, such as improper machine settings, worn tooling, or workpiece inconsistencies

- Adjust honing parameters, inspect tooling, and make necessary corrections

- Implement corrective actions to prevent recurrence of the defects

5. What types of surface finishes can be achieved through honing, and how are they measured?

- Honing can produce surface finishes ranging from rough to superfine

- Surface roughness is measured using instruments such as profilometers or surface texture analyzers

- Commonly used parameters for quantifying surface roughness include Ra (average roughness), Rz (average maximum height of peaks and valleys), and Rq (root mean square roughness)

6. How do you select the appropriate honing stones and abrasives for different applications?

- Consider workpiece material, desired surface finish, and honing process

- Select abrasives with appropriate grain size, hardness, and bond type

- Refer to industry standards or manufacturer recommendations for specific honing applications

- Conduct trial runs to optimize honing parameters and ensure desired results

7. What are the safety precautions you observe when operating honing machines?

- Wear appropriate personal protective equipment, including safety glasses, gloves, and earplugs

- Securely mount workpieces to prevent slippage or ejection

- Ensure proper ventilation to minimize exposure to dust and abrasives

- Maintain a clean and organized work area to avoid tripping hazards

- Follow established safety protocols and lockout procedures during maintenance and repairs

8. How do you contribute to continuous improvement in the honing process?

- Monitor honing operations and identify areas for optimization

- Participate in process improvement initiatives and suggest innovative solutions

- Stay up-to-date with industry best practices and advancements in honing technology

- Provide feedback to management on potential process improvements

9. How do you work effectively as part of a production team?

- Communicate effectively with colleagues and supervisors

- Follow established work instructions and quality standards

- Assist other team members as needed to maintain production flow

- Contribute to a positive and collaborative work environment

10. What are your expectations for this role and how do you see yourself adding value to our organization?

- Eager to contribute my skills and experience to enhance the company’s honing capabilities

- Confident in my ability to produce high-quality honed parts consistently and efficiently

- Excited about working with experienced professionals and contributing to the overall success of the team

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Precision Honer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Precision Honer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Precision Honer is an individual who operates a honing machine to improve the surface finish and dimensional accuracy of metal components. Their expertise lies in honing, a precise machining process that involves abrading a workpiece with a bonded abrasive tool to achieve a smooth and accurate surface.

1. Honing Machine Operation

The primary responsibility of a Precision Honer is to skillfully operate a honing machine by following established procedures. This involves setting up the machine according to specifications, including the selection and installation of appropriate abrasives and honing stones.

- Set up and calibrate the honing machine to meet specific job requirements.

- Select and install suitable abrasives and honing stones based on the material and desired finish.

- Monitor the honing process and make necessary adjustments to maintain optimal conditions.

2. Workpiece Handling and Inspection

Precision Honers are responsible for handling workpieces with great care throughout the honing process. This includes loading and unloading parts, ensuring proper alignment, and verifying dimensional accuracy using measuring tools.

- Load and unload workpieces safely and efficiently.

- Inspect workpieces before and after honing to ensure conformance to specifications.

- Measure and record workpiece dimensions and surface finish using appropriate tools.

3. Abrasive Maintenance

Maintaining and dressing the abrasive tools used in honing is crucial for achieving desired surface finishes. A Precision Honer must possess the skills to dress and condition abrasive stones to maintain their cutting efficiency.

- Dress and condition abrasive stones using specialized equipment.

- Monitor and maintain proper abrasive condition to ensure optimal performance.

- Replace abrasives when necessary to maintain consistent surface finishes.

4. Quality Control and Documentation

Precision Honers play a vital role in ensuring the quality of honed components. They are responsible for monitoring the honing process, inspecting workpieces, and maintaining accurate records.

- Monitor and maintain quality standards throughout the honing process.

- Inspect and measure honed components to verify conformance to specifications.

- Maintain accurate records of honing parameters and inspection results.

Interview Tips

To ace an interview for a Precision Honer position, it is essential to prepare thoroughly and showcase your expertise in honing operations. Here are some tips to help you succeed:

1. Research the Company and Job Description

Take the time to thoroughly research the company you are interviewing with and the specific job description. This will demonstrate your interest and enthusiasm for the position and allow you to tailor your answers to the interviewer’s expectations.

- Visit the company’s website to learn about their products, services, and culture.

- Review the job description carefully and identify key skills and responsibilities.

2. Highlight Your Honing Experience

The primary focus of the interview will be on your honing experience and expertise. Be prepared to discuss your skills in operating a honing machine, selecting abrasives, and maintaining quality standards. Provide specific examples of your successful honing projects.

- Describe your experience in operating different types of honing machines.

- Explain your knowledge of abrasive selection and the impact on surface finish.

- Share examples of how you have maintained quality standards and resolved honing issues.

3. Emphasize Quality Control and Inspection Techniques

Precision Honing involves stringent quality control measures. Highlight your understanding of inspection techniques and your ability to ensure the accuracy and surface finish of honed components. Discuss the tools and methods you use to inspect workpieces.

- Explain your familiarity with industry standards for surface finish and dimensional tolerance.

- Describe the inspection tools and techniques you are proficient in using.

- Share examples of how you have identified and resolved quality issues.

4. Showcase Problem-Solving and Troubleshooting Abilities

Honing operations often require problem-solving and troubleshooting skills. Be prepared to discuss your approach to identifying and resolving common honing issues. Provide examples of how you have overcome challenges and improved the honing process.

- Explain how you diagnose and troubleshoot honing problems based on workpiece characteristics.

- Describe your experience in optimizing honing parameters to achieve desired results.

- Share examples of how you have implemented improvements to the honing process.

Next Step:

Now that you’re armed with the knowledge of Precision Honer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Precision Honer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini