Are you gearing up for an interview for a Tool Sharpener position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Tool Sharpener and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

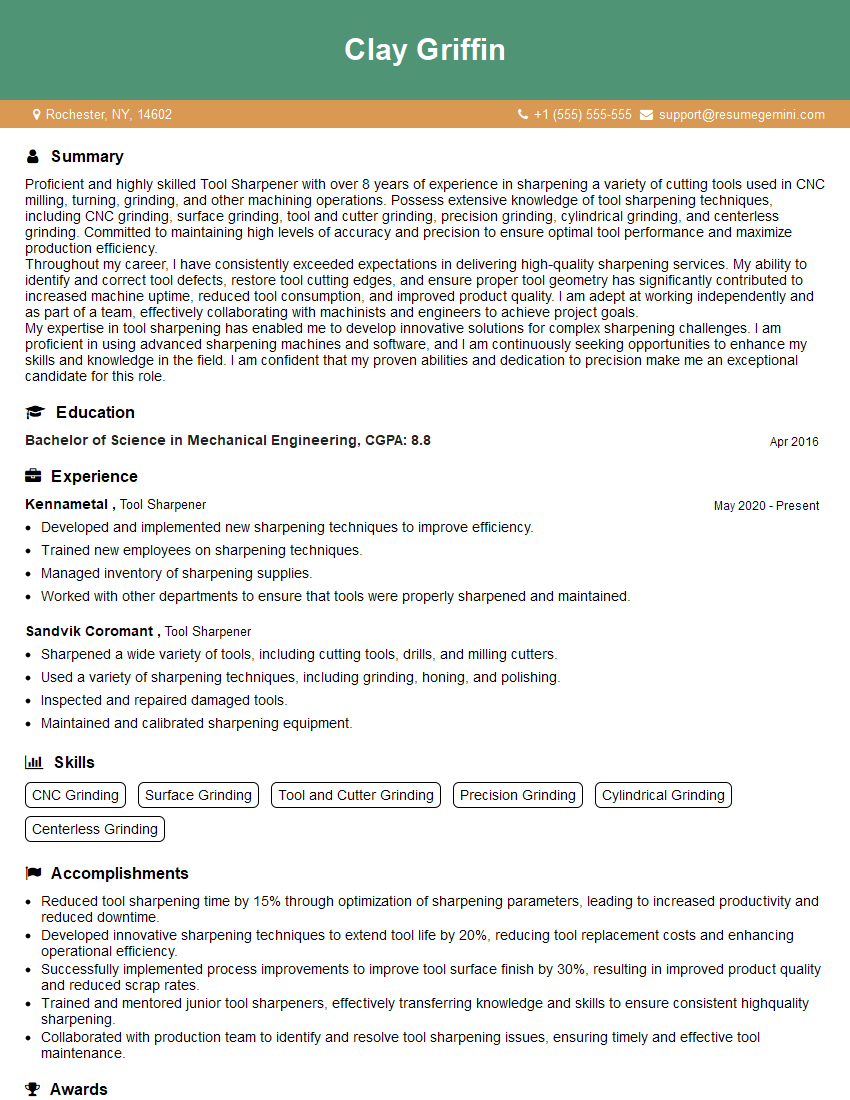

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool Sharpener

1. What are the different types of tool sharpening equipment that you are familiar with?

- Grinders: Bench grinders, pedestal grinders, and hand-held grinders

- Sharpening stones: Water stones, oil stones, and diamond stones

- Honing tools: Strops, steels, and diamond hones

- Specialized equipment: Lathe-mounted tool grinders, CNC tool grinders, and end mill sharpeners

2. What factors should be considered when selecting the correct cutting angle for a tool?

Material of the workpiece

- Harder materials require steeper cutting angles

- Softer materials require shallower cutting angles

Type of operation

- Roughing operations require larger cutting angles

- Finishing operations require smaller cutting angles

Tool material

- Carbide tools can handle larger cutting angles

- High-speed steel tools require smaller cutting angles

3. How do you ensure the accuracy of your sharpening process?

- Using precision measuring tools such as micrometers and calipers

- Regularly calibrating sharpening equipment

- Following manufacturer’s instructions and recommendations

- Inspecting sharpened tools under magnification to ensure proper geometry

4. What is the difference between grinding and honing?

- Grinding removes material to shape and sharpen the tool

- Honing refines the edge of the tool, removing burrs and creating a smooth, polished surface

5. How do you handle sharpening tools made of different materials, such as carbide, high-speed steel, and diamond?

- Carbide: Use diamond grinding wheels and light pressure to avoid chipping

- High-speed steel: Use aluminum oxide or silicon carbide grinding wheels and adjust pressure based on hardness

- Diamond: Use specialized diamond-coated grinding wheels or laser sharpening

6. What safety precautions should be taken when sharpening tools?

- Wear appropriate safety gear, including eye protection, gloves, and a dust mask

- Secure tools properly and use a sharpener with a safety guard

- Be aware of potential hazards such as flying sparks and sharp edges

7. How do you determine the proper grit size for a grinding wheel or sharpening stone?

- Coarser grits (lower numbers) remove more material and are used for initial shaping

- Finer grits (higher numbers) create a smoother finish and are used for honing

- Consider the material of the tool and the desired sharpness

8. What is the importance of coolant when sharpening tools?

- Cools the tool and prevents overheating, which can damage the tool

- Lubricates the grinding process, reducing friction and wear

- Washes away metal particles, preventing clogging and ensuring a clean surface

9. How do you troubleshoot common sharpening problems, such as chatter, burrs, and uneven edges?

- Chatter: Ensure the tool is securely held, adjust the grinding speed, and use a finer grit

- Burrs: Hone the edge at a slightly lower angle or use a finer grit

- Uneven edges: Check the sharpness of the grinding wheel, adjust the tool’s angle, and use a steady hand

10. What are the latest advancements in tool sharpening technology?

- CNC-controlled tool grinders for high precision and repeatability

- Laser sharpening for specialized tools and complex shapes

- Abrasive waterjet sharpening for burr-free edges and reduced heat distortion

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool Sharpener.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool Sharpener‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool Sharpeners are responsible for maintaining the sharpness and functionality of cutting tools used in various industries. Their primary duties and responsibilities include:

1. Tool Inspection and Assessment

Examine cutting tools to determine their condition, such as wear, damage, or deformation.

- Assess the sharpness of tools and identify the appropriate sharpening techniques.

- Record the condition of tools before and after sharpening for quality control purposes.

2. Sharpening and Refinement

Utilize specialized equipment and techniques to sharpen tools, including grinders, honing stones, and abrasive wheels.

- Grind, hone, and lap tools to achieve desired sharpness and cutting performance.

- Adjust grinding angles and apply appropriate cutting fluids to optimize sharpening outcomes.

3. Quality Control and Testing

Inspect sharpened tools to ensure they meet the required specifications and performance standards.

- Conduct cutting tests or use specialized gauges to evaluate sharpness and cutting ability.

- Monitor tool performance during use to identify any issues or areas for improvement.

4. Maintenance and Repair

Perform routine maintenance on sharpening equipment to ensure optimal functionality.

- Replace worn or damaged parts, such as grinding wheels or abrasive belts.

- Troubleshoot and resolve any equipment malfunctions to minimize downtime.

Interview Tips

Preparing for a Tool Sharpener interview requires thorough research and a clear understanding of the job’s responsibilities. Here are some tips to help you ace the interview:

1. Research the Industry and Company

Familiarize yourself with the industry in which the tool sharpening services are used. Research the company’s background, products or services, and their reputation in the market.

2. Highlight Your Skills and Experience

Emphasize your expertise in tool sharpening techniques and your ability to assess and maintain cutting tools. Showcase your proficiency in using various sharpening equipment and your knowledge of different cutting materials.

3. Prepare Examples of Your Work

If possible, bring examples of your sharpened tools or provide photographic evidence of your work. This demonstrates your practical skills and attention to detail.

4. Be Prepared to Discuss Safety and Quality

Tool sharpening involves potentially hazardous equipment and sharp objects. Highlight your commitment to safety and your understanding of industry regulations. Discuss your quality control processes and your ability to meet or exceed performance standards.

5. Show Enthusiasm and Interest

Express your genuine interest in the tool sharpening profession and your eagerness to contribute to the company’s success. Demonstrate your passion for precision and attention to detail.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tool Sharpener, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tool Sharpener positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.